Rice biscuit capable of being brewed into paste as well as preparation method and eating method thereof

A biscuit and brewing technology, applied in the fields of rice biscuit products and their preparation and consumption, can solve the problems of difficulty in forming an ideal paste, high water temperature requirements, and little attention to performance, and achieve uniform distribution, accelerated dissolution, Modulation of easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation process of embodiment 1 biscuit

[0052] Recipe: 100 parts of puffed whole rice flour, 20 parts of oil, 50 parts of maltitol liquid, 15 parts of eggs, 30 parts of erythritol, 4 parts of ammonium bicarbonate, 1 part of sodium bicarbonate, 0.5 parts of soybean lecithin, silicon dioxide 0.5 parts, 0.5 parts of salt, 0.1 parts of special enzyme S200 for crisp biscuits.

[0053] The preparation process is:

[0054] 1. Filling:

[0055] The first step: use eggs to dissolve sodium bicarbonate, ammonium bicarbonate and salt to obtain material 1.

[0056] Step 2: put oil, maltitol liquid, erythritol, material 1, and soybean lecithin into a blender, stir until there are no particles, and all materials are evenly distributed to obtain material 2.

[0057] Step 3: Add puffed whole rice flour, special enzyme S200 for crispy biscuits, and silicon dioxide into material 2, and stir until there is no dry powder.

[0058] 2. Forming:

[0059] Use a circular mold for ...

Embodiment 2

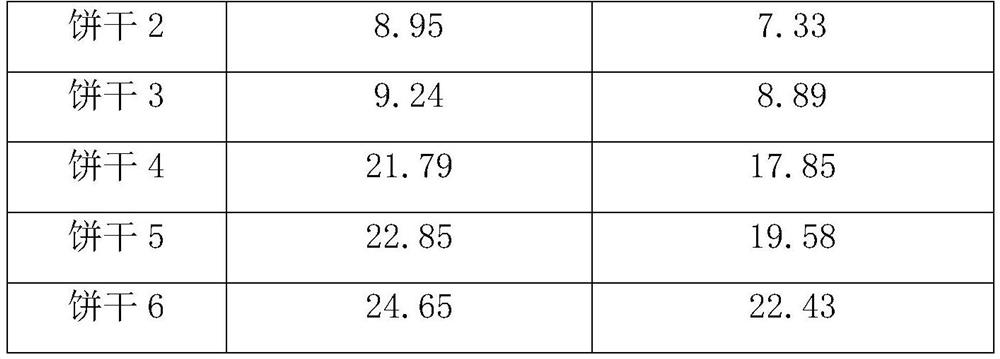

[0071] The crispness of embodiment 2 biscuits

[0072]The brittleness was detected using the above-mentioned apparatus: the brittleness was characterized by the number of space ruptures, and the brittleness was characterized by the maximum force corresponding to the strain. The results are shown in Table 1: The results are similar to those of the manual evaluation, indicating that the addition of protease and amylase has a significant effect on the improvement of crispness.

[0073] Table 1. Crisp evaluation

[0074] biscuit Number of space ruptures (times / mm) Maximum stress versus strain Cookies 1 5.71±1.23 0.39±0.03 Cookies 2 6.02±0.91 0.37±0.03 Cookies 3 5.85±1.01 0.41±0.06 Cookies 4 5.72±0.94 0.39±0.17 Cookies 5 4.79±0.88 0.42±0.21 Cookies 6 3.87±0.79 0.48±0.11

[0075] Note: Average value of five measurements.

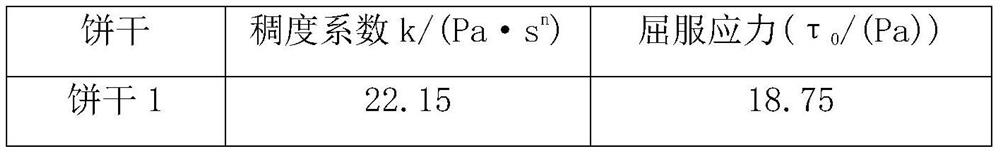

[0076] Example 2 Biscuit brewing performance

[0077] Determination of brewing performance-related v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com