Dry-method mixing device and mixing method for super capacitor pole piece material

A supercapacitor, dry mixing technology, applied in mixers with rotating containers, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problem of insufficient mixing uniformity, low fault tolerance, and low mixing efficiency. problems, to achieve the effect of improving mixing efficiency, high fault tolerance, and ensuring mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

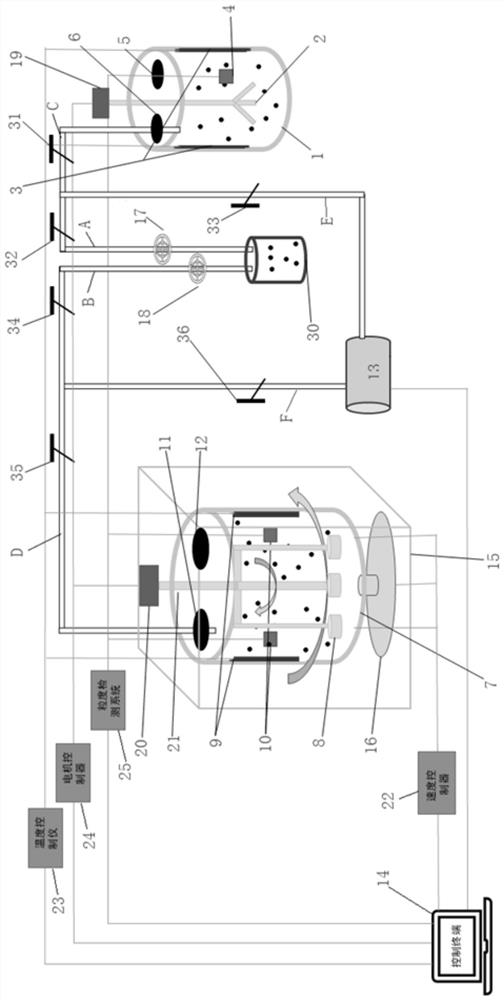

[0051] Such as figure 1 As shown, a dry mixing device for supercapacitor electrode materials includes: a storage tank 30 , a primary mixing system, a secondary mixing system, a vacuum pump 13 and a control terminal 14 .

[0052] A storage tank 30, the storage tank 30 is provided with a feed pipe A and a discharge pipe B; wherein, the feed pipe A is provided with a primary filter 17, and the discharge pipe B is provided with two Stage filter 18, after the supercapacitor pole piece material is mixed through one stage, before entering the storage tank 30, pass through and filter 17 to ensure that the supercapacitor pole piece material that does not mix and meet the requirements cannot enter the storage tank 30, and will Before the supercapacitor pole piece material in the storage barrel 30 is extracted into the secondary material cylinder 7, it also needs to pass through the secondary filter 18 to ensure that the supercapacitor pole piece material passing into the secondary mater...

Embodiment 2

[0062] A dry mixing method for a supercapacitor pole material, applied to the above dry mixing device for a supercapacitor pole material, comprising the following steps:

[0063] Turn on the primary heating mechanism 3 and obtain the actual ambient temperature in the primary barrel 1. When the actual ambient temperature in the primary barrel 1 reaches the ambient temperature of the primary barrel 1 set by the control terminal 14, perform Next step; what needs to be explained is that the ambient temperature of the first-stage barrel 1 set by the control terminal 14 is greater than or equal to 40°C, and the range of humidity is between 5% and 20%, so as to ensure the environmental state during the first-stage mixing. Temperature and humidity are ideal. When each environmental parameter does not reach the set value of the control terminal 14, the temperature controller 23 operates to calculate the heating time, and controls the operation of the primary heating mechanism 3 (the no...

Embodiment 3

[0075] S1, turn on the primary heating mechanism 4, detect the relative humidity in the primary barrel 1 at the present stage, and compare it with the parameters set by the control terminal 14 (the conventional set temperature is 40°C, and the humidity range is 20%), and the temperature is controlled The instrument 23 runs, calculates the heating time, and controls the primary heating mechanism 3 to run for 4 minutes to ensure that the internal environment of the primary barrel 1 is at a dry level;

[0076] S2, test run: turn on the motor 19 to drive the first-stage stirring mechanism 2 to run (at a speed of 2000rpm), the running time is set to 30s, and observe whether the operation of the first-stage material barrel 1 and the first-stage stirring mechanism 2 is stable;

[0077] S3, after the operation of S2 is correct, open the primary feed inlet 5, close the primary discharge port 6 and the first valve 31, and use 10% polyvinylidene fluoride (PVDF) of 8kg activated carbon, 1k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com