Adsorption material with selectivity and preparation method thereof

An adsorption material and selective technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of limited application, complex preparation methods, etc., achieve good oil absorption capacity, simple modification process, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

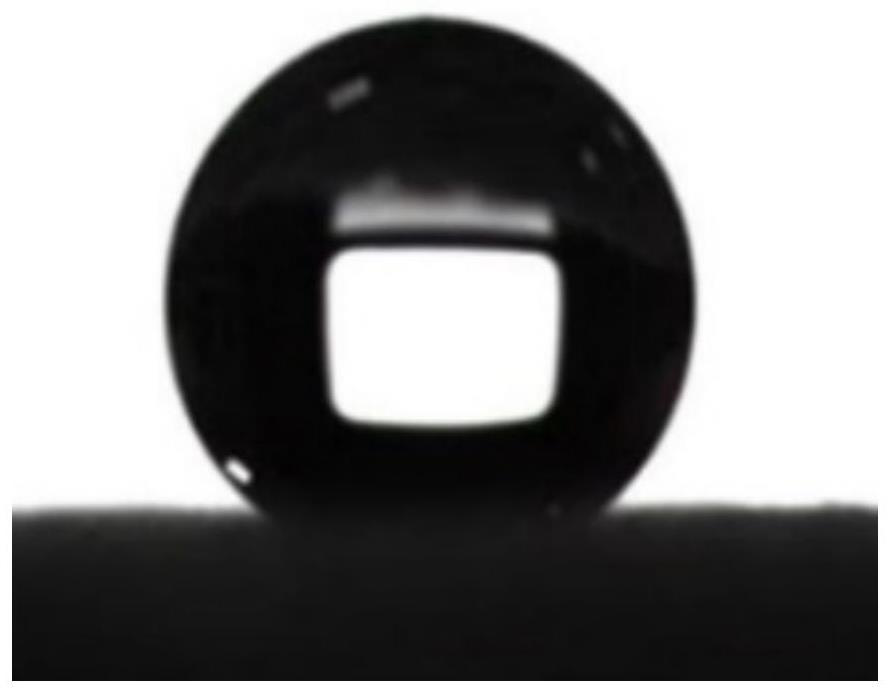

[0028] Embodiment 1: as figure 1 Shown, a kind of selective adsorption material preparation method comprises the following steps:

[0029] (1) Mix vinyltrimethoxysilane and ethanol evenly (the ratio of the amount of substances is 1:5), add acid to adjust the pH to 3, then stir to complete the hydrolysis process, then add alkali to adjust the pH to 9 for gelation, wait After the gel is formed, it is aged for 24 hours and dried to constant weight to obtain a block of airgel, which is ground through a 400-mesh sieve to obtain airgel powder, and the powder with a mass fraction of 5% is ultrasonically dispersed in n-hexane to form a suspension liquid.

[0030] (2) Immerse the commercial polyurethane sponge cut into pieces with a viscosity of 500cs polydimethylsiloxane, 10wt% methyltrimethoxysilane and n-hexane mixture and stir for 1 hour, then pour the prepared suspension into Among them, the mass ratio of commercial polyurethane sponge to airgel particles is 1:10, the sponge is ...

Embodiment 2

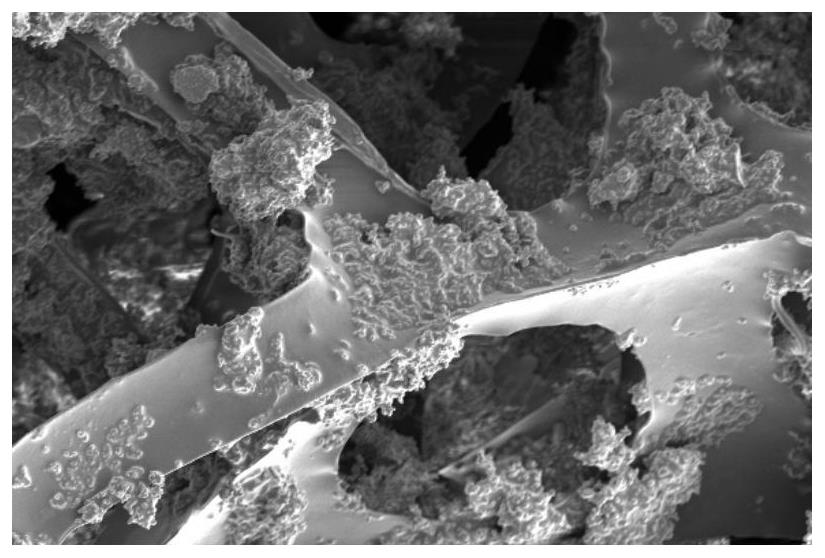

[0031] Embodiment 2: as figure 2 Shown, a kind of selective adsorption material preparation method comprises the following steps:

[0032] (1) Mix vinyltrimethoxysilane and ethanol evenly (the ratio of the amount of substances is 1:10), add acid to adjust the pH to 4 and then stir to complete the hydrolysis process, then add alkali to adjust the pH to 10 for gelation, wait After the gel is formed, it is aged for 12 hours and dried to a constant weight to obtain a block airgel, which is then ground through a 300-mesh sieve to obtain an airgel powder, and the powder with a mass fraction of 7% is ultrasonically dispersed in n-hexane to form a suspension liquid.

[0033] (2) Immerse the commercial polyurethane sponge cut into pieces with a viscosity of 2000cs polydimethylsiloxane, 5wt% propyltriacetoxysilane and n-hexane mixture and stir for 1 hour, then pour the prepared suspension The mass ratio of sponge to airgel particles was 1:5. After stirring for 1 hour, the sponge was ...

Embodiment 3

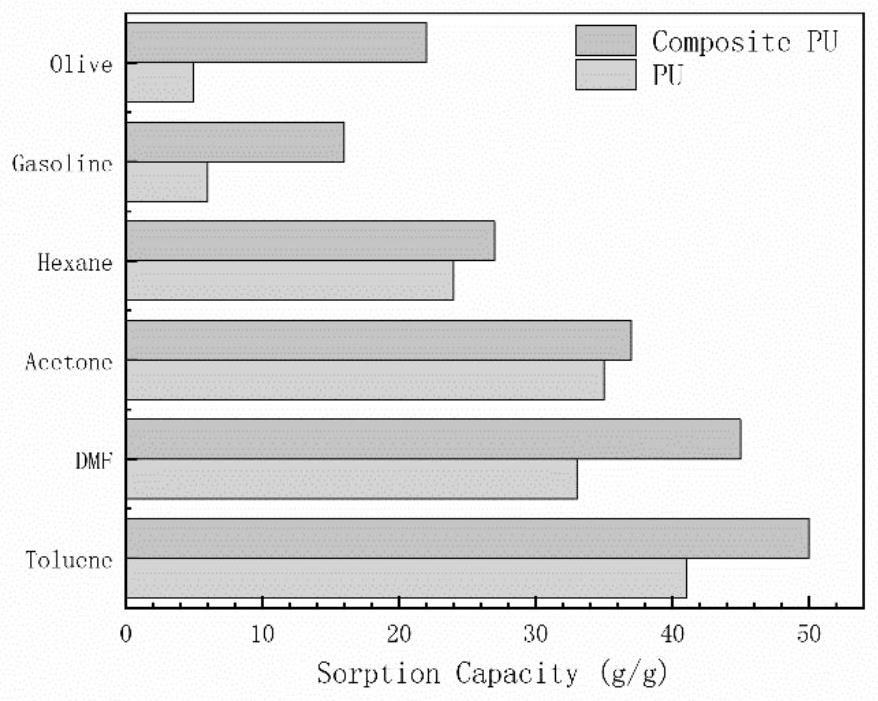

[0034] Embodiment 3: as image 3 Shown, a kind of selective adsorption material preparation method comprises the following steps:

[0035] (1) Mix vinyltrimethoxysilane and ethanol evenly (the ratio of the amount of substances is 1:15), add acid to adjust the pH to 2 and then stir to complete the hydrolysis process, then add alkali to adjust the pH to 8 for gelation, wait After the gel is formed, it is aged for 36 hours and dried to constant weight to obtain a block of airgel, which is then ground through a 600-mesh sieve to obtain an airgel powder, and the powder with a mass fraction of 10% is ultrasonically dispersed in n-hexane to form a suspension liquid.

[0036] (2) Immerse the commercial polyurethane sponge cut into pieces with a viscosity of 5000cs polydimethylsiloxane, 10wt% methyl tributylketoxime silane and n-hexane mixed solution and stir for 1 hour, then prepare the suspension Pour it into it, the mass ratio of sponge to airgel particles is 1:15, continue to sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com