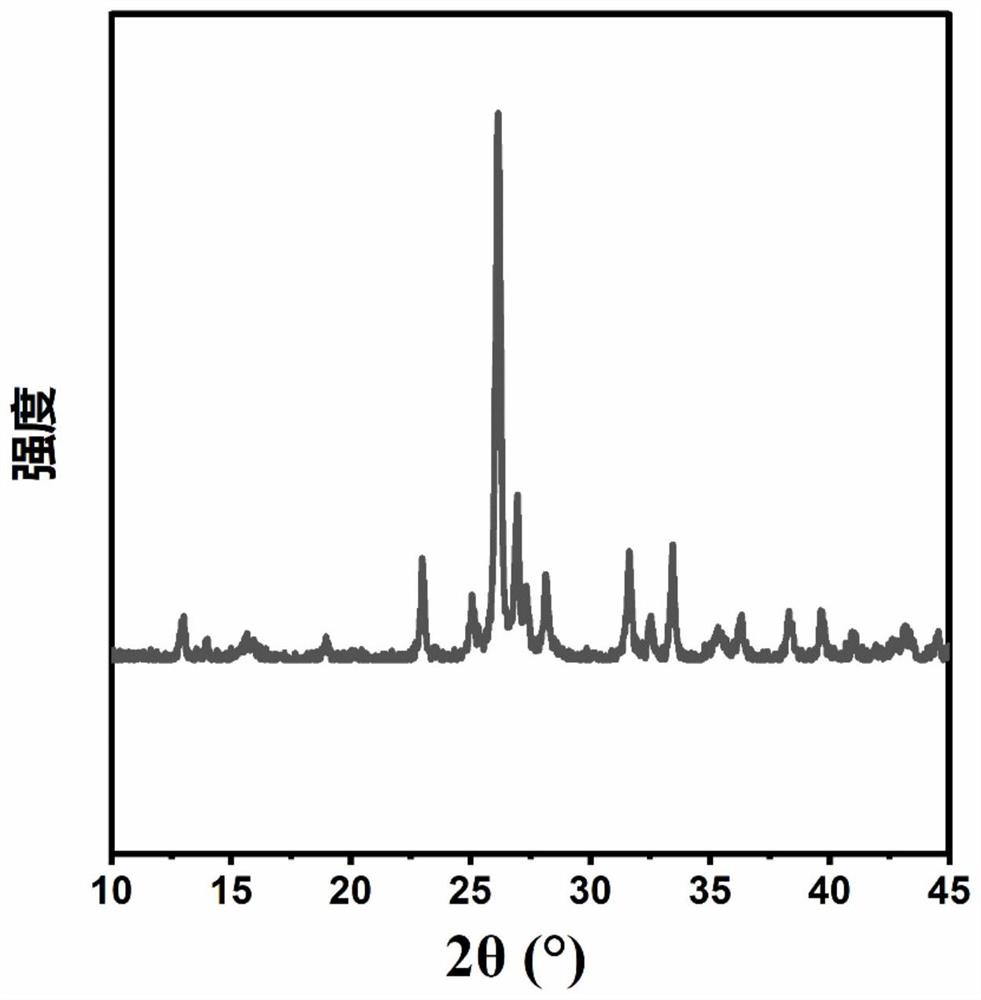

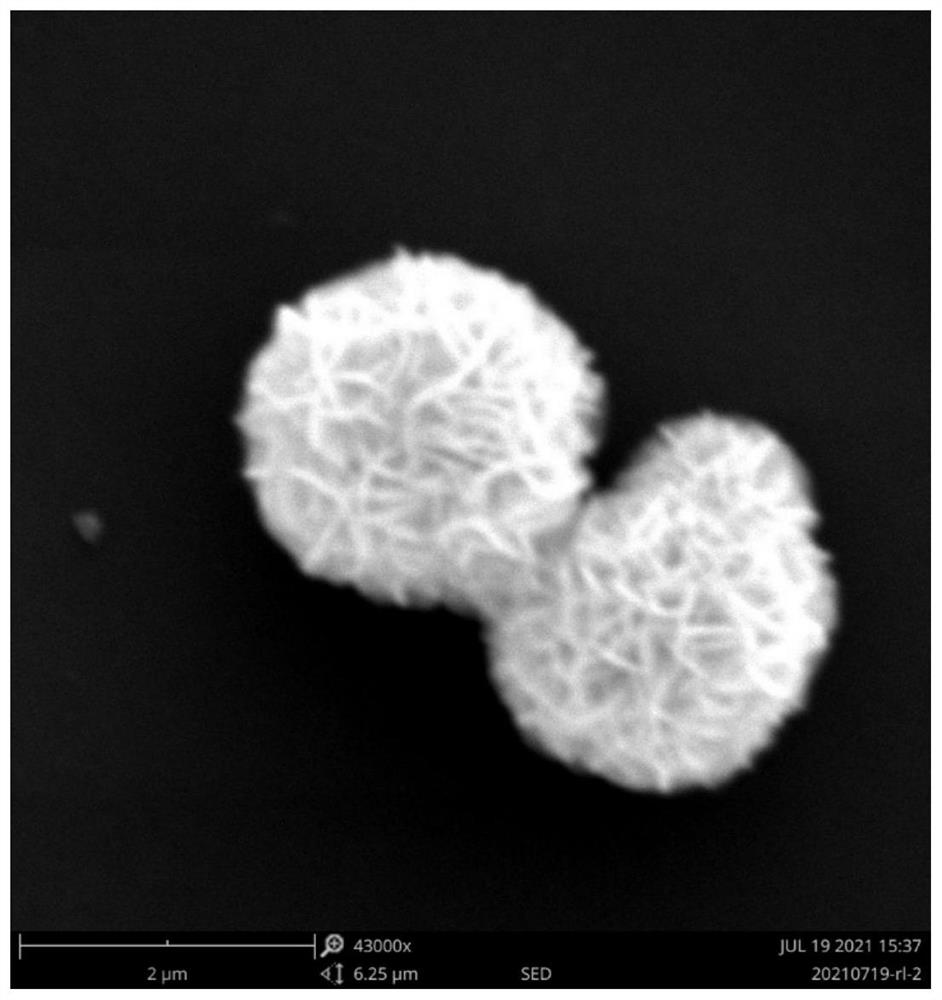

Nanosheet self-assembled spherical ferrous molybdate material as well as preparation method and application thereof

A ferrous molybdate, self-assembly technology, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of instability of ferrous iron, low symmetry, low thermodynamic stability, etc., and achieve product morphology The effect of regularity, low cost, excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a nanosheet self-assembled spherical ferrous molybdate (FeMoO 4 ) The preparation method of material, comprises the following steps:

[0029] First, ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 ) is the molybdenum source, and the amount that takes 1.0mmol is dissolved in 20mL deionized water and dissolves, and this moment adds thiourea (30mmol) and constantly stirs and fully mixes; Simultaneously, 1.0mmol ferrous sulfate hydrate (FeSO 4 ·7H 2 O) dissolved in 15mL deionized water (the molar ratio of molybdenum source to iron source is 1:1), and slowly added to the mixed solution of molybdenum salt and thiourea; the reaction solution was fully stirred at room temperature for 20min, and after ultrasonication for 5min , transfer the reaction precursor reaction solution to a microwave hydrothermal special reaction kettle, and place it in a microwave reactor for reaction. The microwave reaction temperature is 220°C, and the reaction time is 60min...

Embodiment 2

[0032] A kind of self-assembled spherical ferrous molybdate (FeMoO) of the present embodiment 4 ) The preparation method of material, its preparation method is the same as the preparation method of embodiment 1, and difference is, molybdenum source uses Na 2 MoO 4 .

Embodiment 3

[0034] A kind of self-assembled spherical ferrous molybdate (FeMoO) of the present embodiment 4 ) The preparation method of material, its preparation method is the same as the preparation method of embodiment 1, and difference is that ferrous salt uses ferrous chloride hydrate (FeCl 2 4H 2 O).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com