Component adjusting method and device for acidic copper electroplating replenishing solution or electroplating replenishing solution of insoluble anode

A technology of acidic electroplating and component adjustment, which is applied in the direction of electrolytic components, electrolytic process, cells, etc. It can solve the problems of increased production cost, damage to the electroplating layer, and affecting the quality of electroplating, so as to reduce production cost, improve cost performance, and benefit stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

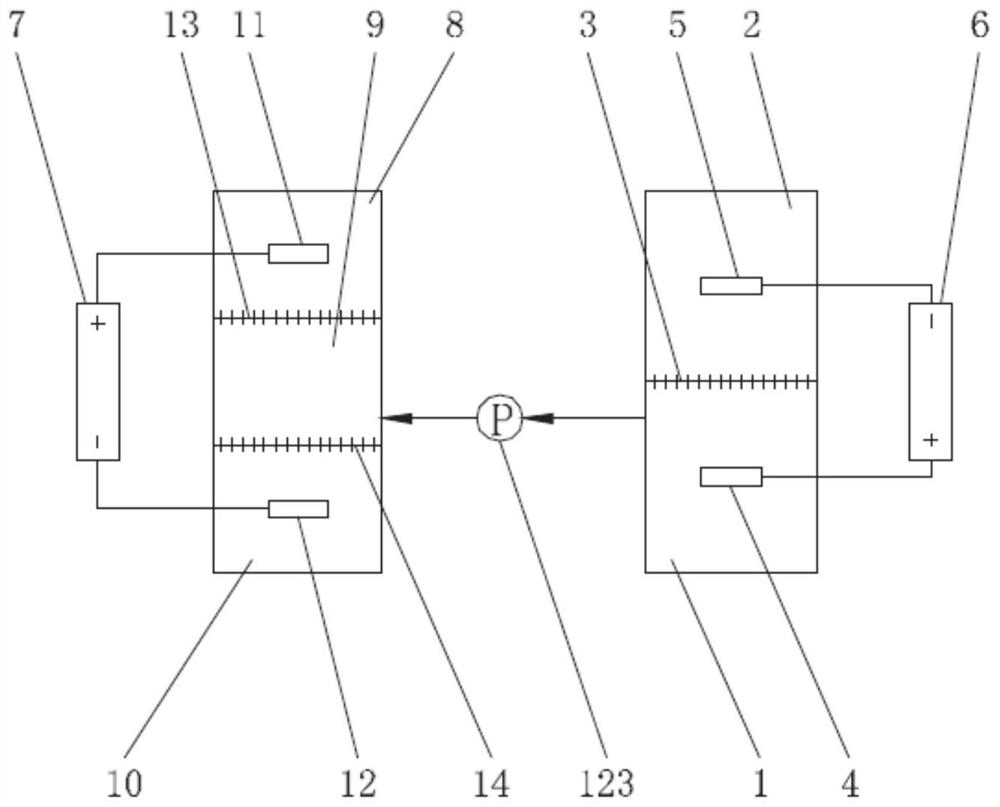

[0150] Such as figure 1 Shown, be the component adjustment device of acidic electroplating copper plating solution or electroplating replenishment liquid of the present invention, comprise No. 1 electrolysis device and No. 2 electrolysis device, No. 1 electrolysis device consists of No. 1 electrolyzer anode area 1, No. 1 electrolyzer cathode area 2. The No. 1 electrolytic tank separator 3, the No. 1 electrolytic anode 4, the No. 1 electrolytic cathode 5 and the No. 1 electrolytic power supply 6. The No. 1 electrolysis anode 4 and the No. 1 electrolysis cathode 5 are respectively connected to the positive pole and the negative pole of the No. 1 electrolysis power supply 6 . The No. 2 electrolysis device consists of No. 2 electrolysis power supply 7, No. 2 electrolysis anode area 8, No. 2 composition adjustment area 9, No. 2 electrolysis cathode area 10, No. 2 electrolysis anode 11, No. 2 electrolysis cathode 12, and No. 2 electrolysis cell separator Composed of A13, No. 2 elec...

Embodiment 2

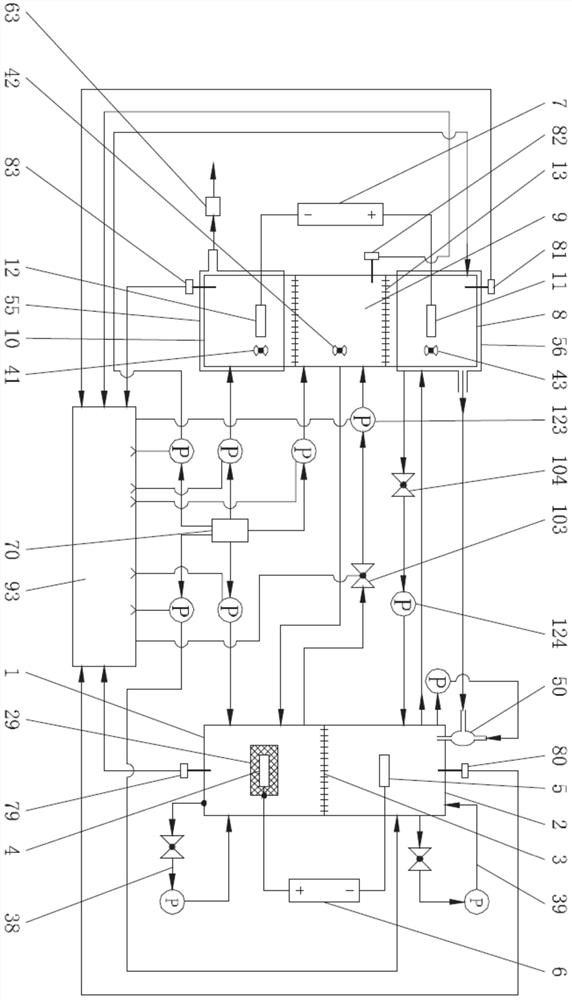

[0162] Such as figure 2 Shown, be the component adjustment device of a kind of acid electroplating copper plating bath of the present invention or electroplating replenishment liquid, and its difference with embodiment 1 is:

[0163] The No. 1 electrolysis anode area 1 and the No. 2 composition adjustment area 9 are respectively connected with the pipeline and the return pipeline provided with the pump 123 and the valve 103 to form a circulation. The pipeline with the pump 124 and the valve 104 and the return pipeline are double-connected to form a circulating liquid flow loop.

[0164] A gas collection tank cover 55 is arranged above the No. 2 electrolysis cathode area 10, and the collected hydrogen is discharged through the hydrogen discharge pipe 63.

[0165] A gas collection tank cover 56 is set above the No. 2 electrolysis anode area 8, and the oxygen released from the solution in the No. 2 electrolysis anode area is dissolved into the No. 1 electrolysis cathode through...

Embodiment 3

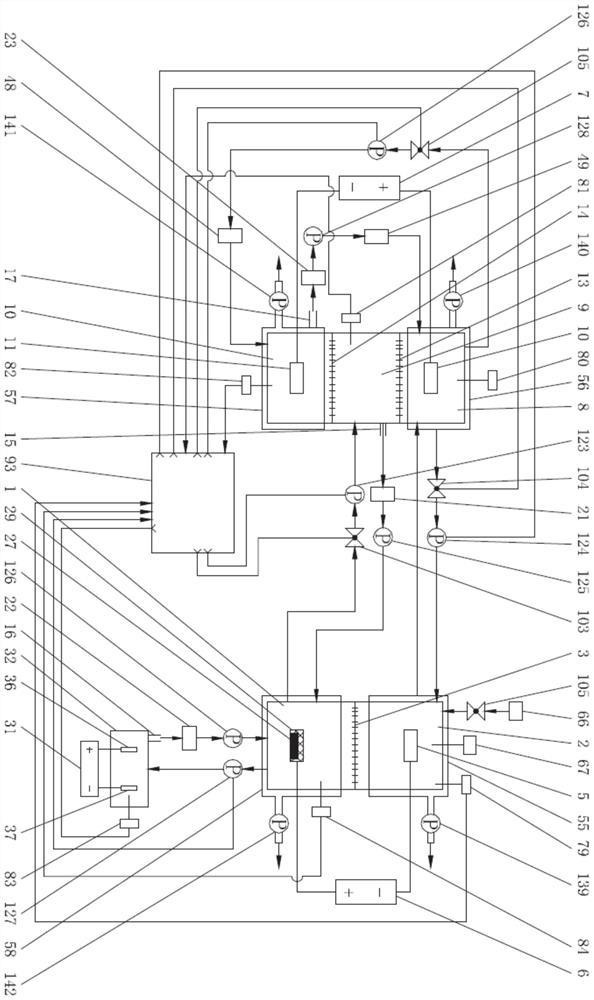

[0178] Such as image 3 Shown, be the component adjustment device of a kind of acid electroplating copper plating bath of the present invention or electroplating replenishment liquid, and its difference with embodiment 1 is:

[0179] The overflow port 15 of No. 1 electrolytic anode zone 1 and No. 2 composition adjustment zone 9 is connected with the pipeline of pump 125, buffer tank 21 and the pipeline of pump 123 and valve 103 respectively. Liquid flow circulation loop; Between the electrolysis cathode area 2 and the No. 2 electrolysis anode area 8, the pipelines provided with the pump 124 and the valve 103 are respectively connected with the return pipeline to form a liquid flow circulation loop; between the No. 2 electrolysis anode area 8 and the No. 2 electrolysis cathode area 10 Connected by a pipeline provided with a pump 126, a valve 105 and a liquid conduction interrupter 48;

[0180] No. 1 electrolytic anode is a combination of titanium basket 29 loaded with copper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com