Novel laser electronic target

An electronic target and laser technology, which is applied to targets, target indication systems, attack equipment, etc., can solve the problems of inconvenient handling of electronic targets, heavy electronic targets, and inconvenience to carry, etc. cost, reduce complexity and maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

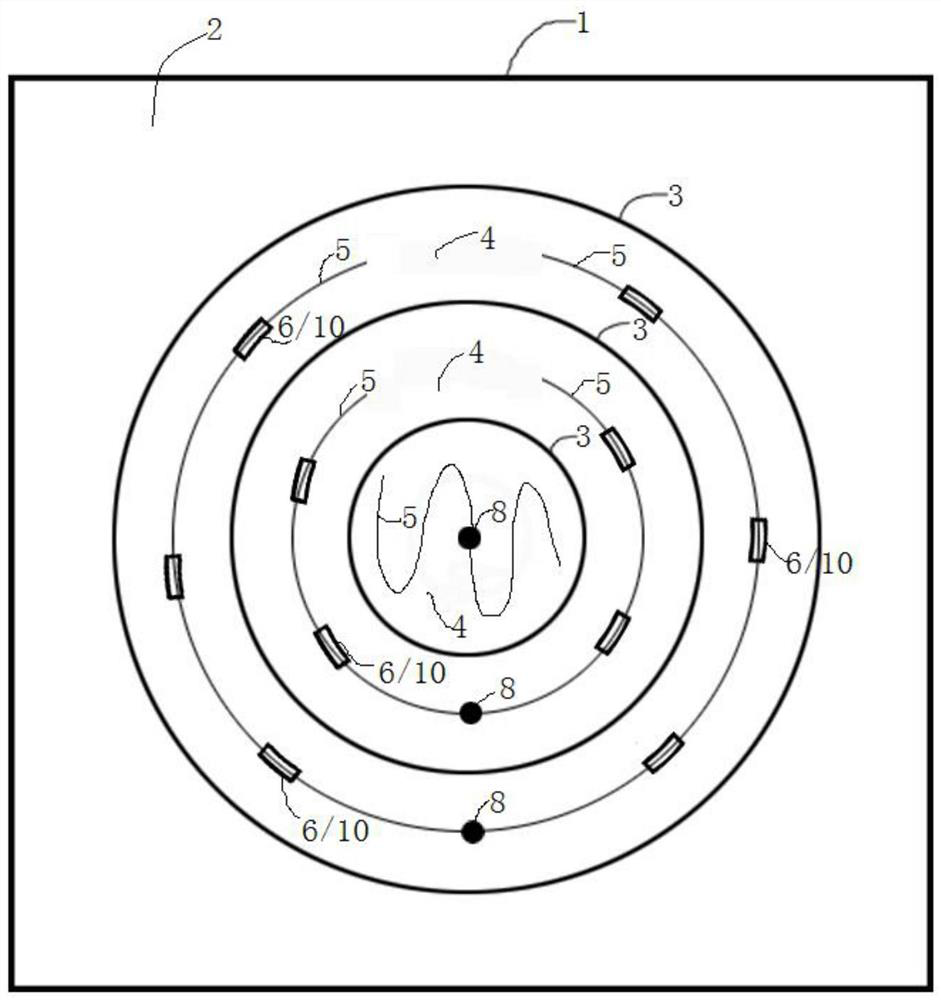

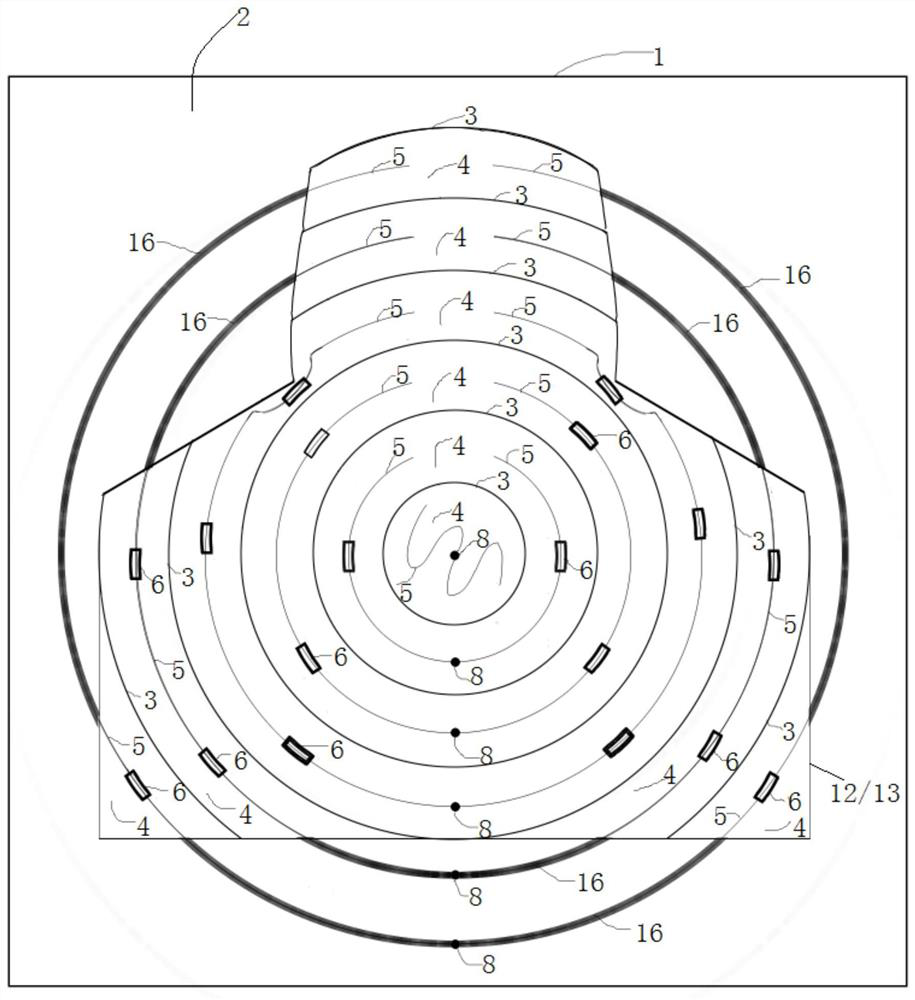

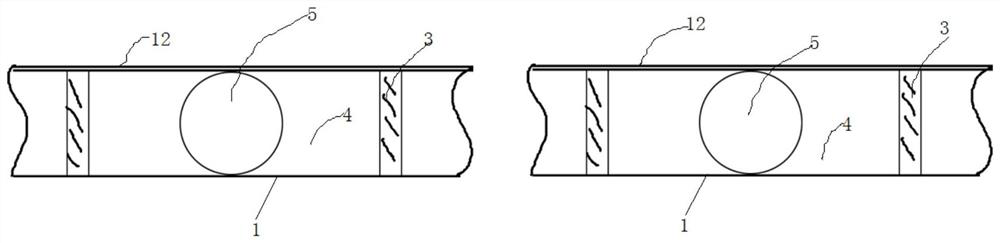

[0042] In this example, if Figure 1-4 As shown, the optical fiber 5 is a side-firing optical fiber, the side of the side-firing optical fiber is the light pickup surface 6 , and one or both end surfaces of the side-firing optical fiber are the light-emitting surface 7 .

[0043] Side-light optical fiber is also called full-body light-emitting optical fiber. It consists of a core material and a skin material. The refractive index of the core material is higher than that of the skin material. The core material is mostly made of transparent polymer or transparent organic matter. Vinyl fluoride, etc. Side-lit optical fibers are usually used for lighting and decoration. When in use, light is irradiated from one or both end faces of side-lit optical fibers and transmitted from the side, that is, through side-lit lighting. Since the light can enter from the end face of the side-light fiber and pass out from the side, then according to the reversible principle of the optical path, t...

example 2

[0047] In this example, if Figure 1-4 As shown, the optical fiber 5 is a side-light fiber, and a cut 9 is provided on the side-light fiber. The side of the side-light fiber and the cut surface at the cut are the light-picking surfaces, and one or both end faces of the side-light fiber are light-emitting surfaces.

[0048] In the foregoing example 1, the side surface of the side-firing optical fiber is used as the light-picking surface, which can achieve the purpose of picking up optical signals. However, after the laser beam is dispersed by diffuse reflection, its intensity will inevitably decrease, and although the side of the side-light fiber can also pick up light, the light-picking ability of the side-light fiber side is worse than that of its end face ( Not only side-lit optical fibers, but also other types of optical fibers have the strongest light-picking ability at the end face. For some types of optical fibers, the cortex is opaque, and the side does not have the lig...

example 3

[0057] In this example, the fiber is a side-light fiber, and a notch is opened on the side-light fiber. The side of the side-light fiber and the notch surface at the notch are the light-picking surfaces, and one or both end faces of the side-light fiber are light-emitting surfaces.

[0058] The difference between this example and Example 2 is that this example creates a notch on the side-light fiber, and the notch refers to cutting off a part of the side-light fiber by a cutter to form a V-shaped notch. Other parts are the same as Example 2, and will not be repeated in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com