Method for manufacturing a magnetic memory element using ru and diamond like carbon hard masks

A technology of magnetic memory and memory elements, applied in static memory, digital memory information, application of conductive/insulating/magnetic materials on magnetic films, etc., can solve the problems that electrons cannot easily pass through, high resistance, etc., and achieve reduction in thickness and data The effect of increased density and reduced shadowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description is of the best mode currently contemplated for carrying out the invention. This description is for the purpose of illustrating the general principles of the invention and is not meant to limit the inventive concepts claimed herein.

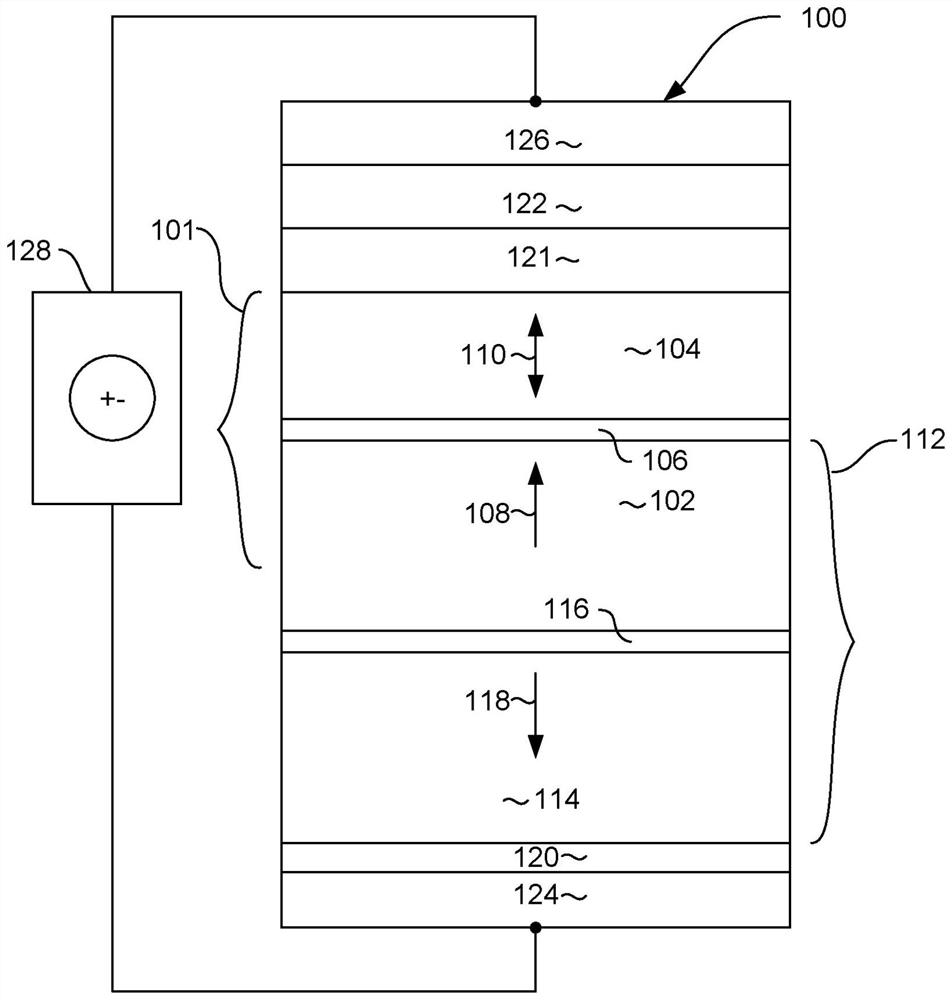

[0020] now refer to figure 1 , the magnetic memory element 100 may be in the form of a vertical magnetic tunnel junction (pMTJ) memory element. The magnetic memory element may include an MTJ 101 which may include a magnetic reference layer 102 , a magnetic free layer 104 , and a thin non-magnetic electrically insulating barrier layer 106 between the magnetic reference layer 102 and the magnetic free layer 104 . The barrier layer 106 can be, for example, an oxide of MgO. The magnetic reference layer has a magnetization 108 fixed in a direction preferably perpendicular to the plane of the layer as indicated by arrow 108 . The magnetically free layer 104 has a magnetization 110 that may be in either of two directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com