Digital screening flexographic preprinting method for wide color corrugated carton

A corrugated box and corrugated paper technology, which is applied in the field of digitally screened flexographic pre-printing of wide-width color corrugated boxes, can solve the problem of inconvenient handling of color levels in graphics, and achieve the goal of saving ink consumption, saving ink consumption, and reducing color shift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Now, the present invention will be described in detail by taking the application of the present invention to the digital screened flexo preprinting of a certain wide-width color corrugated box as an example, and it also has a guiding effect on the application of the present invention to other wide-width color corrugated box digital screened flexo preprinting .

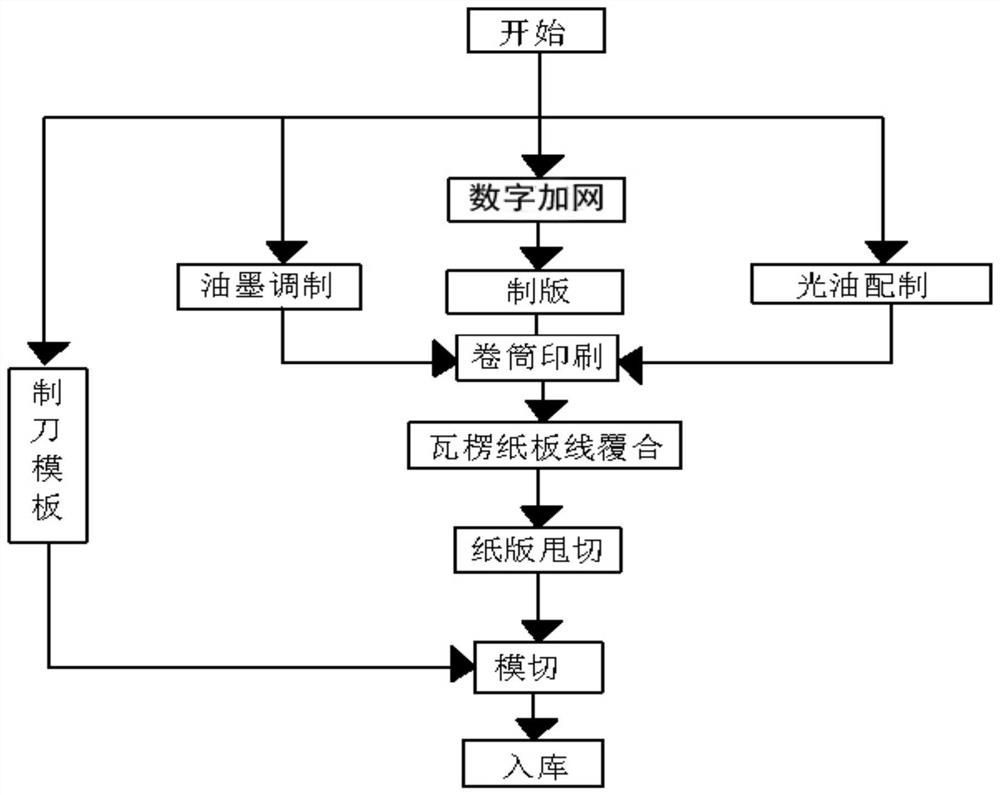

[0054]The digital screen flexographic preprinting method for a wide-width color corrugated box includes a wide-width color corrugated box flexo preprinting method and a digital screen method; wherein, the wide-width color corrugated box flexo preprinting method is Existing technology, including knife template making, ink preparation, varnish preparation, plate making, roll printing, corrugated cardboard line lamination, cardboard cutting, die cutting and warehousing and other processes;

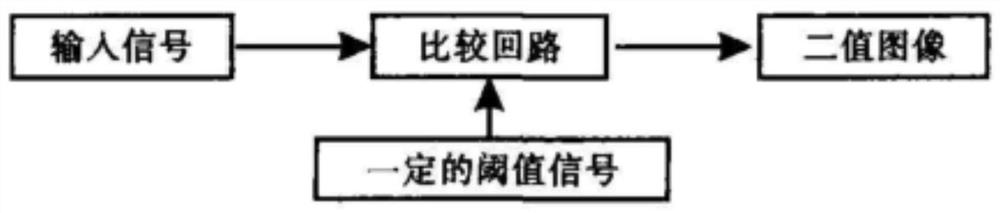

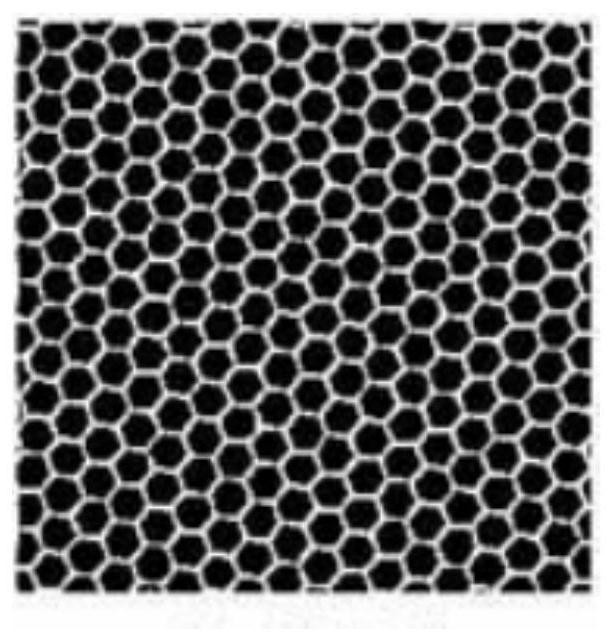

[0055] The digital screening method adopts the digital screening system to realize the generation of flexo printing dots; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com