A kind of mineral powder grinding aid and its preparation method and application

A grinding aid and mineral powder technology, which is applied in the field of building materials, can solve the problems such as the inability to meet the performance requirements of mineral powder, the low activity of slag, and the failure of the mineral powder to achieve the expected use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

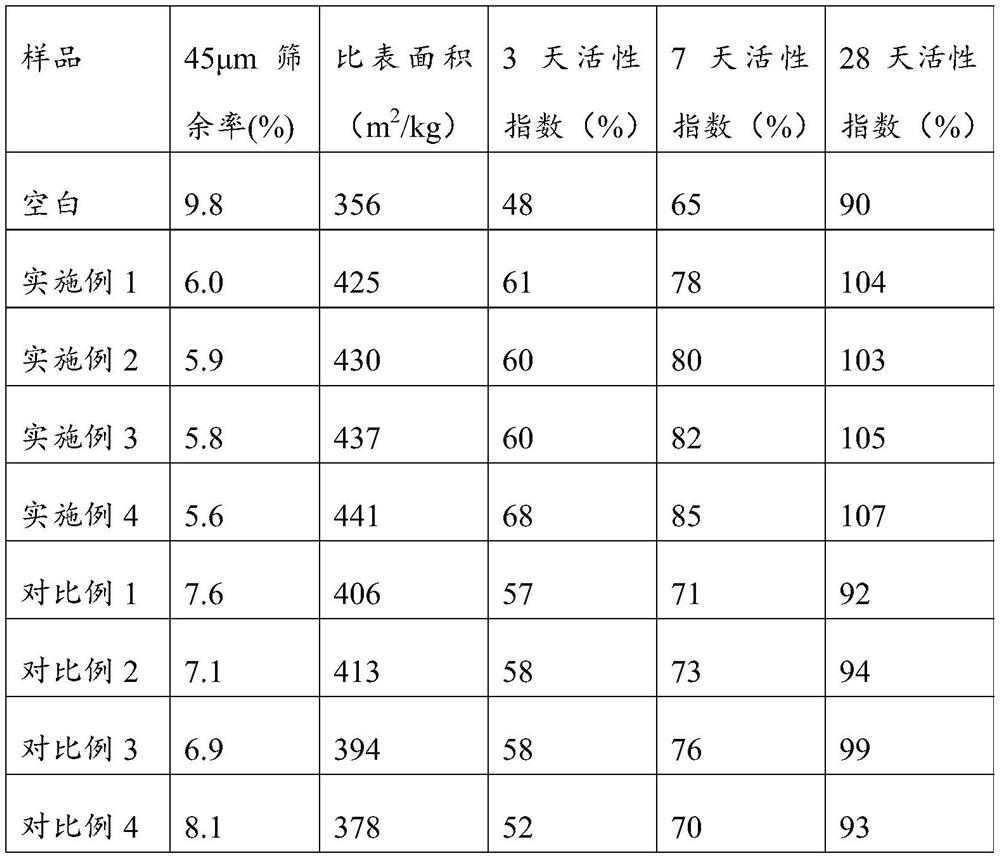

Examples

Embodiment 1

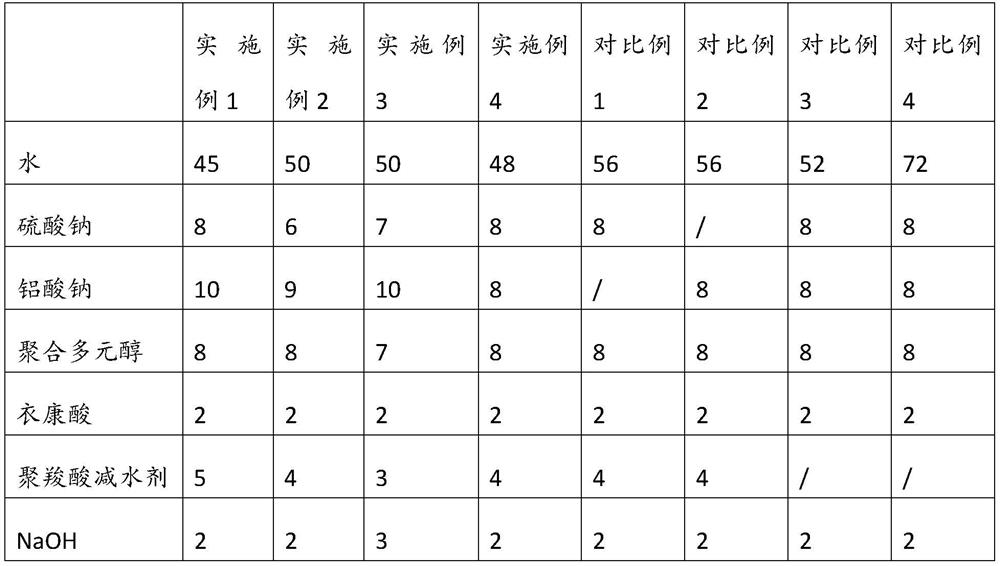

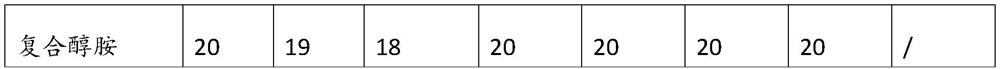

[0065] The present embodiment provides a mineral powder grinding aid, the specific formula is shown in Table 1, the specific preparation method is, under normal temperature and pressure, in order, sodium sulfate, sodium aluminate, polymeric polyol, itaconic acid, Polycarboxylate water reducing agent, NaOH and compound alcohol amine are dissolved in water in turn, and then continue to stir for 20min; in the dissolving process, the former raw material needs to be completely dissolved before adding the latter raw material.

[0066] Wherein, in the present embodiment, the polycarboxylate water reducer is a polycarboxylate water reducer produced from Hunan Zhongyan Building Materials Technology Co., Ltd. and the model is HL-700;

[0067] The compound alcoholamine is a mixture of ethylene oxide-modified diethanolamine and ethylene oxide-modified triethanolamine, and the composition ratio is 1:1;

[0068] The polymerized polyol is obtained by polymerizing ethylene glycol, diethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com