Radome TPU protective film

A technology of protective film and radome, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of radome structural performance and electrical performance degradation, easy generation of static electricity on the radome surface, affecting radio wave transmission, etc. No glue residue VOA emission, good performance, not easy to slip off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of TPU composite layer specifically comprises the following steps:

[0035] (1) The thermoplastic polyurethane elastomer is controlled by a two-stage dehumidification dryer to control the moisture content of the TPU to less than 300ppm, and then the conventional injection molding, extrusion, blow molding or calendering process is performed to prepare the TPU layer, and the thickness is controlled at 125μm;

[0036] (2) Use organosilicon resin as film-forming resin, the amount of aluminum silver paste is 10-15wt%, the amount of mica powder is 12-15wt%, mix evenly through a mixer, and then pass through a two-stage dehumidification dryer to control the moisture below 300ppm, and then pass Film forming by conventional injection molding, extrusion, blow molding or calendering;

[0037] (3) Nano filler TiB 2 The mass ratio with TiC is 1:2, TiB 2 -The proportion of TiC is 4wt%, supplemented by silicone resin, mixed evenly by a mixer, and then controlle...

Embodiment 1

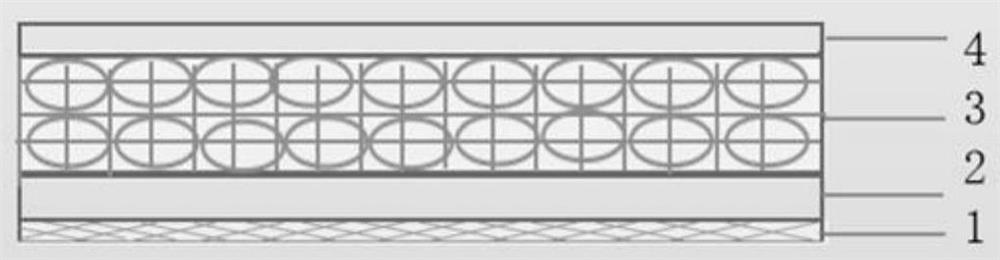

[0042] A TPU protective film for aircraft radome, which includes a release layer, a UV adhesive layer, a TPU composite layer, and an antistatic TPU layer from bottom to top. The thickness of the release layer is 1 μm, and the thickness of the UV adhesive layer is 10 μm. , the antistatic polyurethane layer is based on polyether polyurethane elastomer as the carrier, adding 10% thermoplastic conductive filler masterbatch Nano-Force S by mass, diluting and mixing TPU evenly, and then extruding to prepare the antistatic polyurethane layer, the thickness The antistatic polyurethane layer is directly coated on one surface of the TPU composite layer; the UV adhesive layer is coated on the release layer, and then heated and cured by UV light. The UV adhesive layer has a strong adhesion before UV light. Heli, after UV light, has a strong sticking force, it is not easy to slip off after being attached to the surface of the radome, and it is easy to peel off from the surface of the radome...

Embodiment 2

[0054] A TPU protective film for aircraft radome, which includes a release layer, a UV adhesive layer, a TPU composite layer, and an antistatic TPU layer from bottom to top. The thickness of the release layer is 2 μm, and the thickness of the UV adhesive layer is 12 μm. , the antistatic polyurethane layer is based on polyether polyurethane elastomer as a carrier, adding 15% thermoplastic conductive filler masterbatch Nano-Force S by mass, diluting and mixing TPU evenly, and then extruding to prepare an antistatic polyurethane layer with a thickness of The antistatic polyurethane layer is directly coated on one surface of the TPU composite layer; the UV adhesive layer is coated on the release layer, and then heated and cured by UV light. The UV adhesive layer has a strong adhesion before UV light. Heli, after UV light, has a strong sticking force, it is not easy to slip off after being attached to the surface of the radome, and it is easy to peel off from the surface of the rado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com