Desulfurization device corrosion risk early warning method based on cloud model

A desulfurization device and risk early warning technology, applied in the direction of instruments, data processing applications, resources, etc., can solve problems such as blunt methods, carrying noise, fuzzy or random risk early warning, etc., achieve good discrimination, soft data processing methods, and improve safety The effect of management and equipment management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Next, the technical solutions in the embodiments of the present invention will be described in connection with the embodiments, and embodiments are merely described in the embodiments of the present invention, not all of the embodiments of the present invention. Based on embodiments of the present invention, all other embodiments obtained without making creative labor have not made creative labor premises.

[0071] Taking the raw material gas into the unit of the desulfurization unit of X high-containing sulfur natural gas purifier as an example, the etching risk of the portion is determined by the following steps:

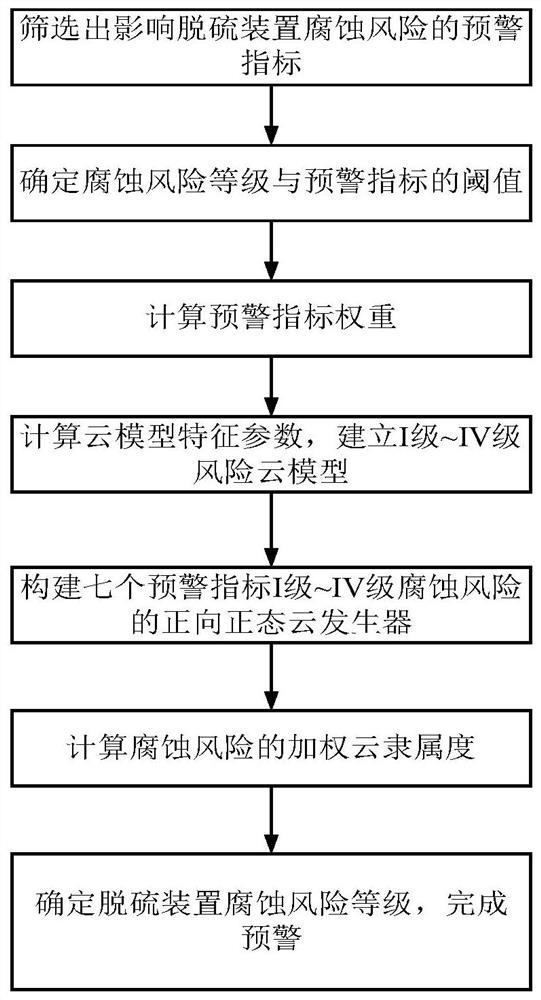

[0072] Step 1: Screen an early warning indicator affecting the risk of corrosion of desulfurization devices;

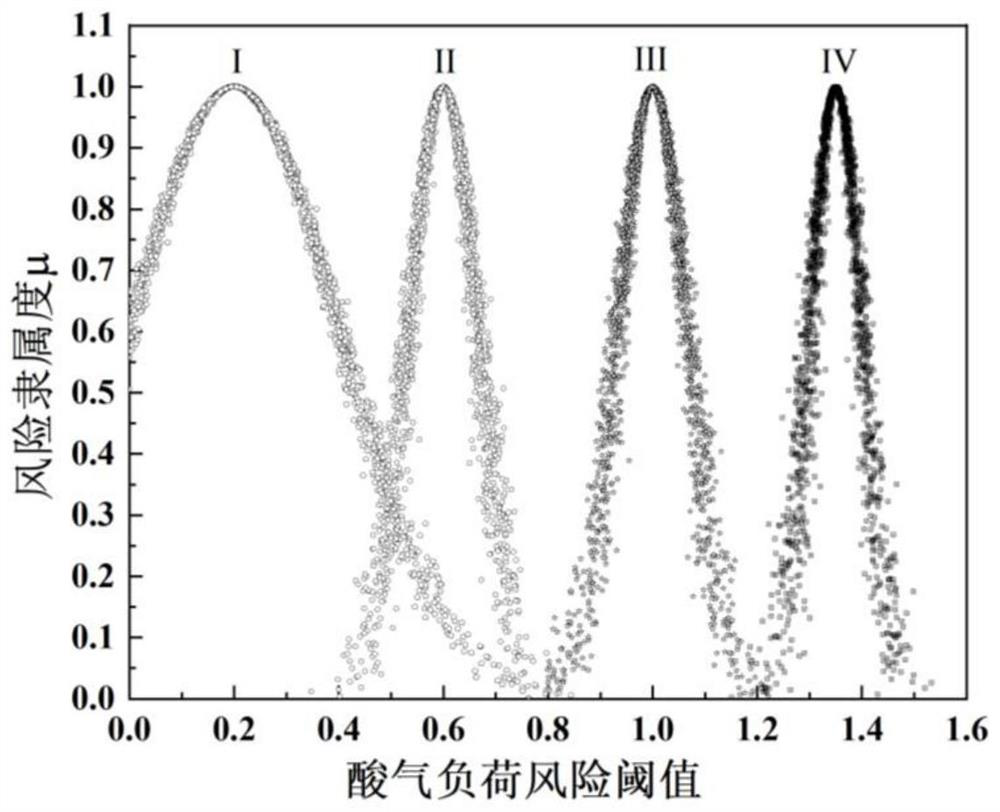

[0073] Specifically: (1) acid gas load 1 mol; (2) chloride ion concentration 261 mg / L; (3) organic thermal stability salt concentration 0mg / L; (4) inorganic thermal stability salt concentration 0 mg / L; (5) Material corrosion resistance is 0.4, 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com