Preparation method of industrial grade card of Internet of Things

An Internet of Things and industrial technology, applied in the field of electronic information, can solve the problems of low pass rate, poor corrosion resistance, complicated process, etc., and achieve the effect of improving efficiency, reducing production cost and increasing corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

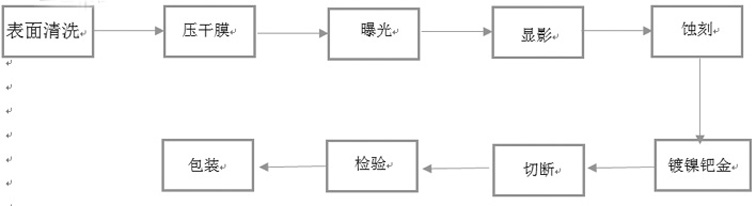

[0045] The preparation method of the described IoT industrial grade card specifically comprises the following steps:

[0046] (1) Surface cleaning

[0047] Choose 194 copper foil with a thickness of 203 microns as the substrate, and clean the substrate to remove oil and surface impurities. Cleaning adopts acid cleaning agent and alkaline cleaning agent in sequence, and the cleaning speed is 1.5 m / min. The acidic cleaning agent uses acetic acid aqueous solution, and the alkaline cleaning agent uses sodium bicarbonate aqueous solution.

[0048] (2) Press dry film

[0049] A photosensitive dry film is hot-pressed on the surface of the cleaned substrate; the temperature for pressing the dry film is: 120°C, the pressure is 0.6kg, and the transmission speed is 2.5 m / min.

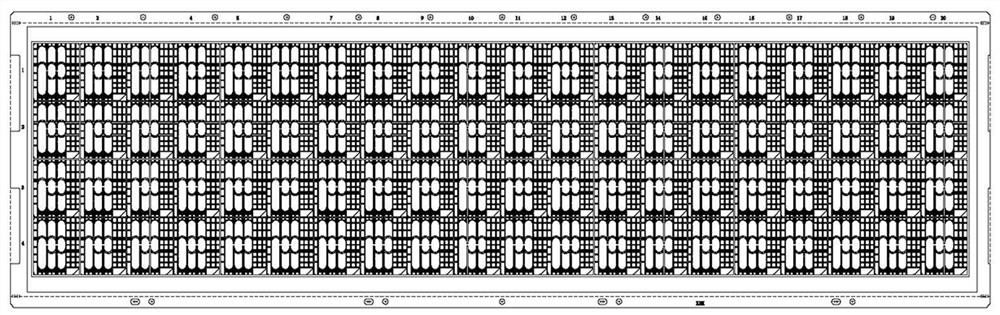

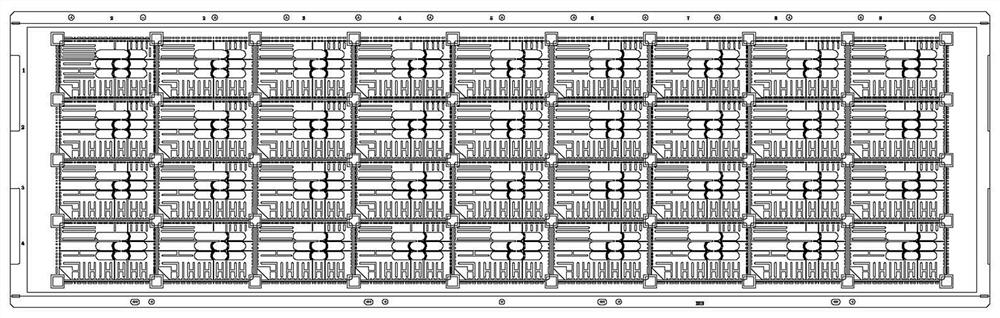

[0050] (3) Exposure

[0051] Design CAD drawings according to the required pattern and shape, import the drawings into the laser direct writing equipment, place the substrate after the dried film on the direct...

Embodiment 2

[0064] The preparation method of the described IoT industrial grade card specifically comprises the following steps:

[0065] (1) Surface cleaning

[0066] Choose 194 copper foil with a thickness of 203 microns as the substrate, and clean the substrate to remove oil and surface impurities. Cleaning uses acidic cleaning agent and alkaline cleaning agent in sequence, and the cleaning speed is 1 m / min. The acidic cleaning agent uses acetic acid aqueous solution, and the alkaline cleaning agent uses sodium bicarbonate aqueous solution.

[0067] (2) Press dry film

[0068] A photosensitive dry film is hot-pressed on the surface of the cleaned substrate; the temperature for pressing the dry film is: 110°C, the pressure is 0.8kg, and the transmission speed is 2 m / min.

[0069] (3) Exposure

[0070] Design CAD drawings according to the required pattern and shape, import the drawings into the laser direct writing equipment, place the substrate after the dried film on the direct wri...

Embodiment 3

[0083] The preparation method of the described IoT industrial grade card specifically comprises the following steps:

[0084] (1) Surface cleaning

[0085] Choose 194 copper foil with a thickness of 203 microns as the substrate, and clean the substrate to remove oil and surface impurities. Cleaning adopts acid cleaning agent and alkaline cleaning agent in sequence, and the cleaning speed is 2 m / min. The acidic cleaning agent uses acetic acid aqueous solution, and the alkaline cleaning agent uses sodium bicarbonate aqueous solution.

[0086] (2) Press dry film

[0087] A photosensitive dry film is hot-pressed on the surface of the cleaned substrate; the temperature for pressing the dry film is: 130°C, the pressure is 0.4kg, and the transmission speed is 3 m / min.

[0088] (3) Exposure

[0089] Design CAD drawings according to the required pattern and shape, import the drawings into the laser direct writing equipment, place the substrate after the dried film on the direct wri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap