Briquetting molded body of rubber composition, method for producing same, rubber composition for crosslinking, and tread for tire

A technology of rubber composition and manufacturing method, which is applied in the direction of tire tread/tread pattern, special tire, tire parts, etc., and can solve the problems of increased viscosity of rubber composition, peeling of rubber composition, and easy pollution of molding molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

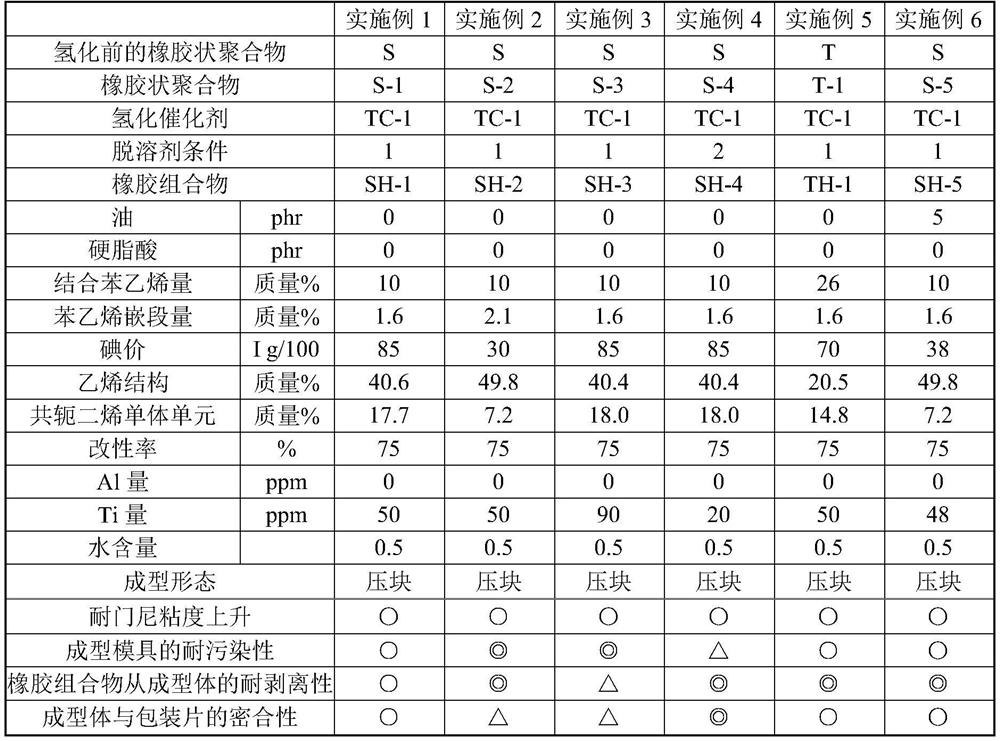

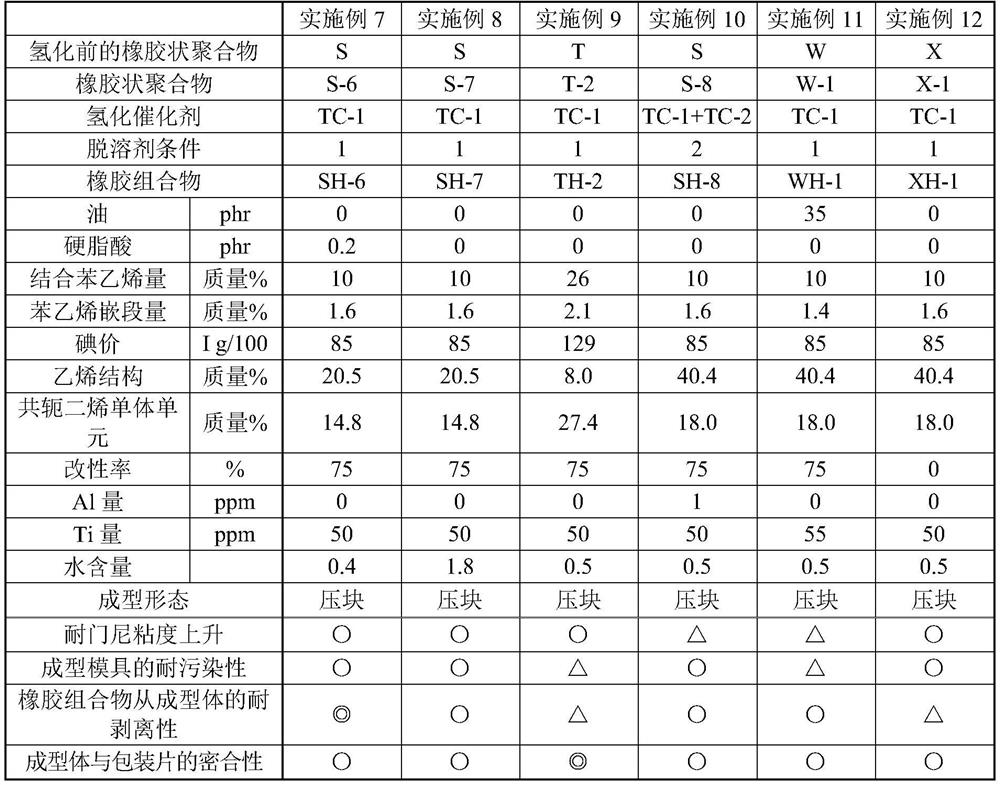

[0270] Hereinafter, the present embodiment will be described in more detail by giving specific examples and comparative examples, but the present embodiment is not limited to the following examples and comparative examples at all.

[0271] Various physical properties in Examples and Comparative Examples were measured by the methods shown below.

[0272] [Physical Properties of Rubbery Polymer (A)]

[0273] (weight average molecular weight (Mw) of the rubber-like polymer (A) before hydrogenation)

[0274] The chromatogram was measured using a GPC measuring device connected to three columns using polystyrene-based gel as a filler, and the weight-average molecular weight of the rubber-like polymer before hydrogenation was determined based on a calibration curve obtained using standard polystyrene (Mw).

[0275] As an eluent, THF (tetrahydrofuran) to which 5 mmol / L of triethylamine was added was used.

[0276] As for the column, a guard column: "TSKguardcolumn SuperH-H" manufactu...

manufacture example 1

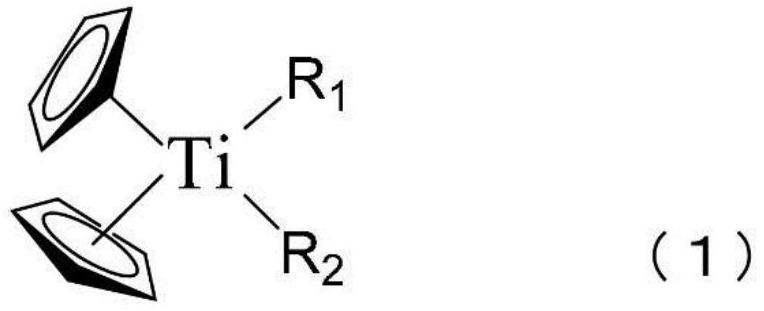

[0360] 2 liters of dried and purified cyclohexane was charged into the nitrogen-purged reaction vessel, and 40 mmoles of bis(η5-cyclopentadiene)bis(p-tolyl)titanium and 1,000 molecular weight about 1,000 were dissolved therein. 2-polybutadiene (1,2-vinyl incorporation about 85%) 150 g. Thereafter, a cyclohexane solution containing 60 millimoles of n-butyllithium was added to the reaction vessel, and reacted at room temperature for 5 minutes, then 40 millimoles of n-butanol was immediately added and stirred to obtain a hydrogenation catalyst (TC-1). The resulting catalyst was stored at room temperature.

manufacture example 2

[0362] 1 liter of dried and purified cyclohexane was put into the reaction vessel replaced with nitrogen, 100 mmoles of bis(η5-cyclopentadiene)titanium dichloride was added, and the mixture containing trimethylaluminum was added while fully stirring. A 200 mmol n-hexane solution was reacted at room temperature for about 3 days to obtain a hydrogenation catalyst (TC-2).

[0363] (polymerization of rubber-like polymer (A))

[0364]

[0365] Using a temperature-controlled autoclave with an internal volume of 40 L and equipped with a stirrer and a jacket as a reactor, add 2,160 g of 1,3-butadiene, 300 g of styrene, and 21,000 g of cyclohexane from which impurities have been removed in advance. g. 30 mmol of tetrahydrofuran (THF) and 3.6 mmol of 2,2-bis(2-tetrahydrofuryl)propane as polar substances, and the internal temperature of the reactor was kept at 46°C.

[0366] 23.9 mmol of n-butyl lithium as a polymerization initiator was supplied to the above-mentioned reactor.

[036...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com