Remediation device and method for organic matter and heavy metal combined polluted soil

A compound pollution and heavy metal technology, applied in the restoration of polluted soil, energy and wastewater treatment, etc., can solve the problems of cumbersome engineering, lack of universal applicability, and complicated equipment, and achieve the effect of flexible operation, low cost, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

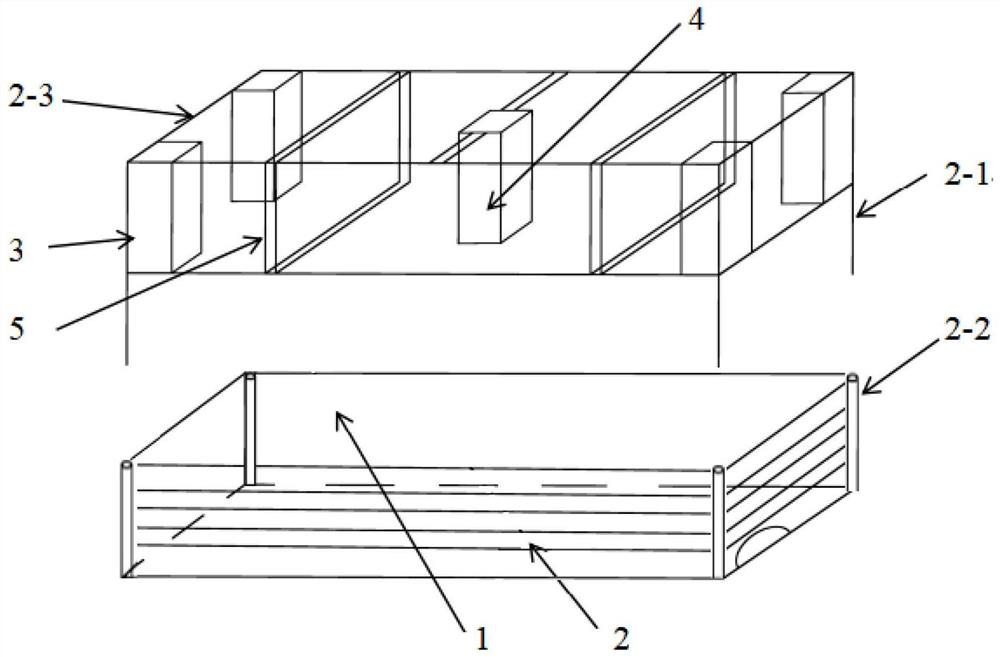

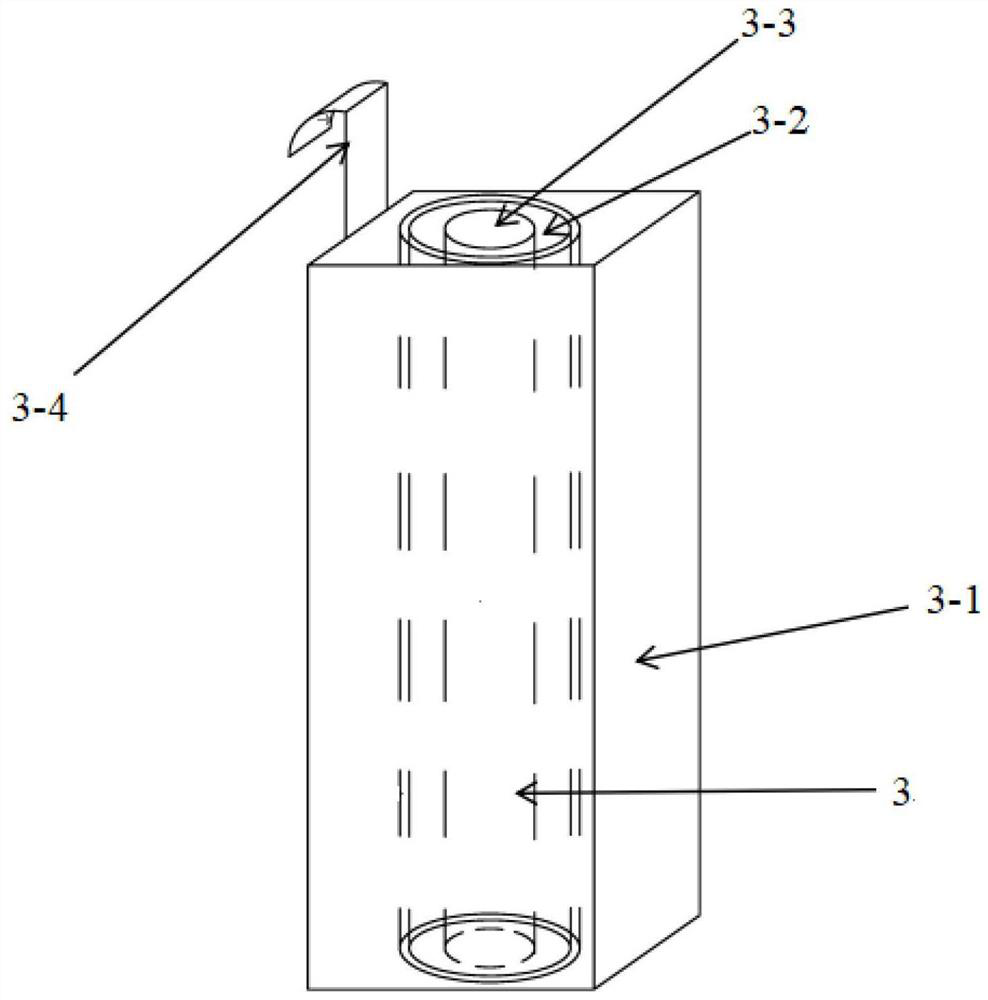

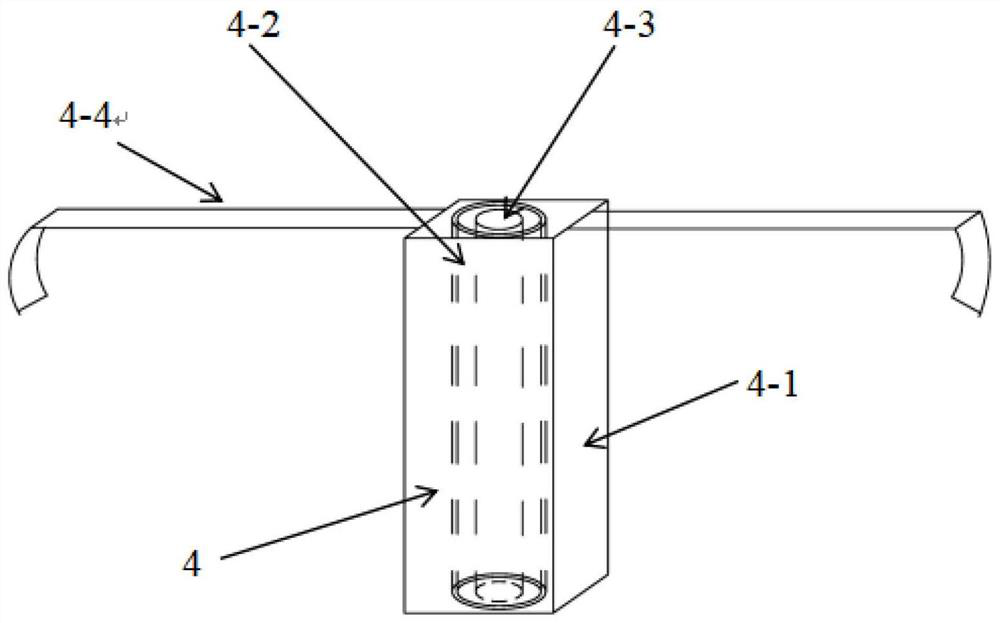

[0063] The purpose of the present invention is to provide a preparation of iron-carbon micro-electrolysis material, and apply it to the osmotic reaction column, combined with electrodynamic repair technology, to make a repair device for organic matter and heavy metal compound polluted soil, including electrolysis chamber box 2 , anodic electrolytic column 3, cathodic electrolytic column 4, osmotic reaction column 5, solar power generation system 6 and rinsing and spraying system 7.

[0064] The box body 2 of the electrolytic box is a cubic structure, which is divided into upper and lower parts, the upper part is a repair room, and the lower part is a permeation room.

[0065] The repair chamber is a hollow body surrounded by four sides, and the four vertical edges of the hollow body have four solid positioning cylinders 2-1 extending downward. When the repair is in progress, the soil to be repaired is loaded into the repair chamber. The four horizontal edges on the top of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com