Mica sheet adhesive tape and preparation method thereof

A mica sheet and tape technology, applied in the direction of adhesives, film/sheet adhesives, adhesive types, etc., can solve the problems of insufficient initial viscosity of tapes, rough surface of mica sheets, poor temperature resistance, etc., to improve adhesion. Stress and thermal stability, rapid wettability, effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a kind of preparation method of mica sheet adhesive tape, comprises the following steps:

[0023] Step 1: Prepare the following raw materials in parts by weight: acrylic acid: 5-8 parts; isooctyl acrylate: 30-32 parts; hydroxyethyl acrylate: 3-5 parts; vinyl acetate: 12-14 parts; stir and mix to obtain a mixed product;

[0024] Step 2: Put the mixed product in the reaction furnace into ethyl acetate: 50-55 parts, turn on the stirring, pass in nitrogen, and raise the temperature to 65-70°C to obtain the polymer;

[0025] Step 3: the following raw materials by weight: polymer: 100 parts; low softening point terpene resin: 5-10 parts; nano silicon dioxide: 3-5 parts; zinc oxide: 3-5 parts; silane coupling agent: 1-2 parts; 1-2 parts of paraffin; 0.5-1 part of isocyanate curing agent; after stirring and mixing, the finished glue is made;

[0026] Step 4: Coat the finished glue on one side of the tissue paper, then attach the release pape...

Embodiment 1

[0031] A preparation method of mica sheet tape, comprising the following steps:

[0032] Step 1: Prepare the following raw materials in parts by weight: acrylic acid: 7 parts; isooctyl acrylate: 31 parts; hydroxyethyl acrylate: 4 parts; vinyl acetate: 13 parts; stir and mix to obtain a mixed product;

[0033] Step 2: Put the mixed product in the reaction furnace into ethyl acetate: 53 parts, turn on the stirring, feed nitrogen, and raise the temperature to 66°C to obtain the polymer;

[0034] Step 3: the following raw materials by weight: polymer: 100 parts; low softening point terpene resin: 7 parts; nano silicon dioxide: 4 parts; zinc oxide: 4 parts; silane coupling agent: 1 part; paraffin wax 1 part ; Isocyanate curing agent: 0.5 part; after stirring and mixing, the finished glue is obtained;

[0035] The low softening point terpene resin is the low softening point terpene resin T-50 of Shanghai Shuixing Industrial Co., Ltd.; the silane coupling agent is a silane coupling ...

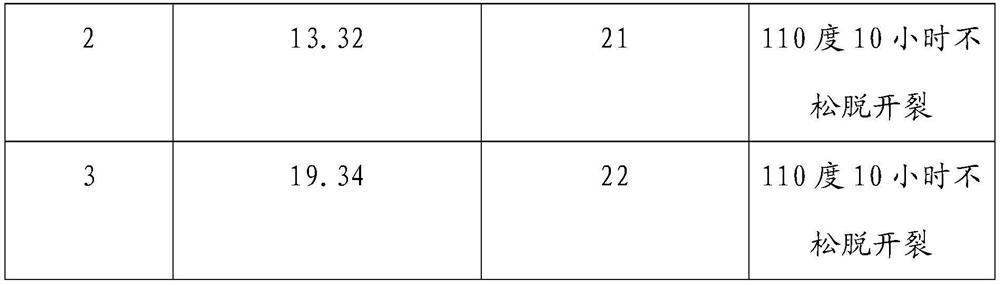

Embodiment 2

[0039] A preparation method of mica sheet tape, comprising the following steps:

[0040] Step 1: Prepare the following raw materials in parts by weight: acrylic acid: 5 parts; isooctyl acrylate: 30 parts; hydroxyethyl acrylate: 3 parts; vinyl acetate: 12 parts; stir and mix to obtain a mixed product;

[0041] Step 2: Put the mixed product into the reaction furnace: 50 parts of ethyl acetate, turn on the stirring, pass in nitrogen, and heat up to 65°C to obtain the polymer;

[0042] Step 3: the following raw materials by weight: polymer: 100 parts; low softening point terpene resin: 5 parts; nano silicon dioxide: 3 parts; zinc oxide: 3 parts; silane coupling agent: 1 part; paraffin wax 1 part ; Isocyanate curing agent: 0.5 part; after stirring and mixing, the finished glue is obtained;

[0043] The low softening point terpene resin is the low softening point terpene resin T-50 of Shanghai Shuixing Industrial Co., Ltd.; the silane coupling agent is a silane coupling agent (KH56...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com