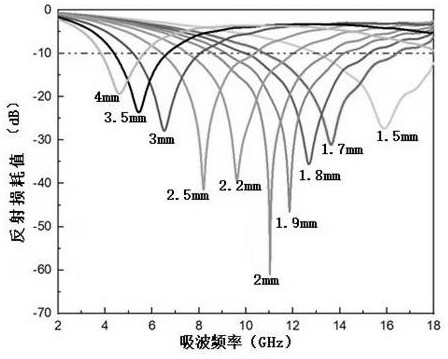

High-entropy alloy wave-absorbing material with reflection loss reaching -60.9dB and preparation method for high-entropy alloy wave-absorbing material

A high-entropy alloy and wave-absorbing material technology, applied in the field of wave-absorbing materials, can solve the problems of high price of Co element, narrow effective absorption bandwidth, complicated preparation process, etc. The effect of electromagnetic absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

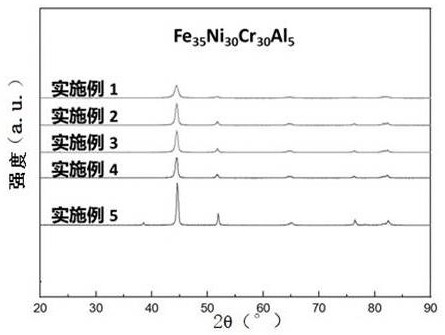

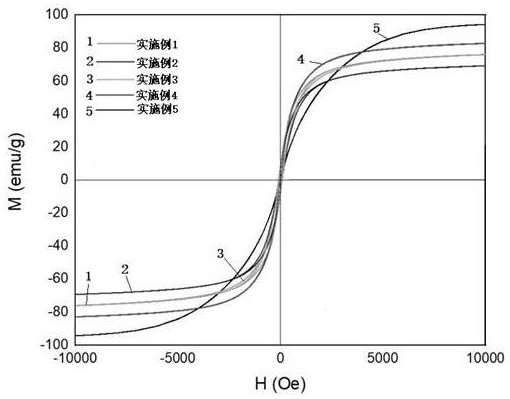

[0034] The molecular formula of the high-entropy alloy absorbing material of this embodiment is Fe 35 Ni 30 Cr 30 Al 5 .

[0035] The preparation method of the high-entropy alloy absorbing material of the present embodiment comprises the following steps:

[0036] Step 1, the target product Fe 35 Ni 30 Cr 30 Al 5Each atomic percentage designed in is converted into mass ratio, then weighs the powder of Fe, Ni, Cr, Al according to mass ratio; The mass purity of the powder of described Fe, Ni, Cr, Al is all greater than 99.5%;

[0037] Step 2, in a glove box full of argon, put 30g of Fe, Ni, Cr, Al powder weighed in step 1 into a ball mill jar with 600g of grinding balls, and add absolute ethanol as process control agent, and then seal the ball mill jar; the balls contain 300g of balls with a diameter of 10mm;

[0038] Step 3, take out the sealed ball mill jar from step 2 from the vacuum glove box, then place it on a planetary ball mill, and perform ball milling for 90 ho...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is: the time of ball milling is 70h.

Embodiment 3

[0045] The difference between this embodiment and embodiment 1 is: the time of ball milling is 50h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com