Anti-pulling type rigidity-controllable piled raft foundation structure and construction method

A technology of piled raft foundation and stiffness, which is applied in the engineering practice of piled raft foundation with controllable stiffness. The problem of limited pullout resistance and loss of pullout resistance can be achieved to improve the anti-seepage ability, strong bonding ability and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

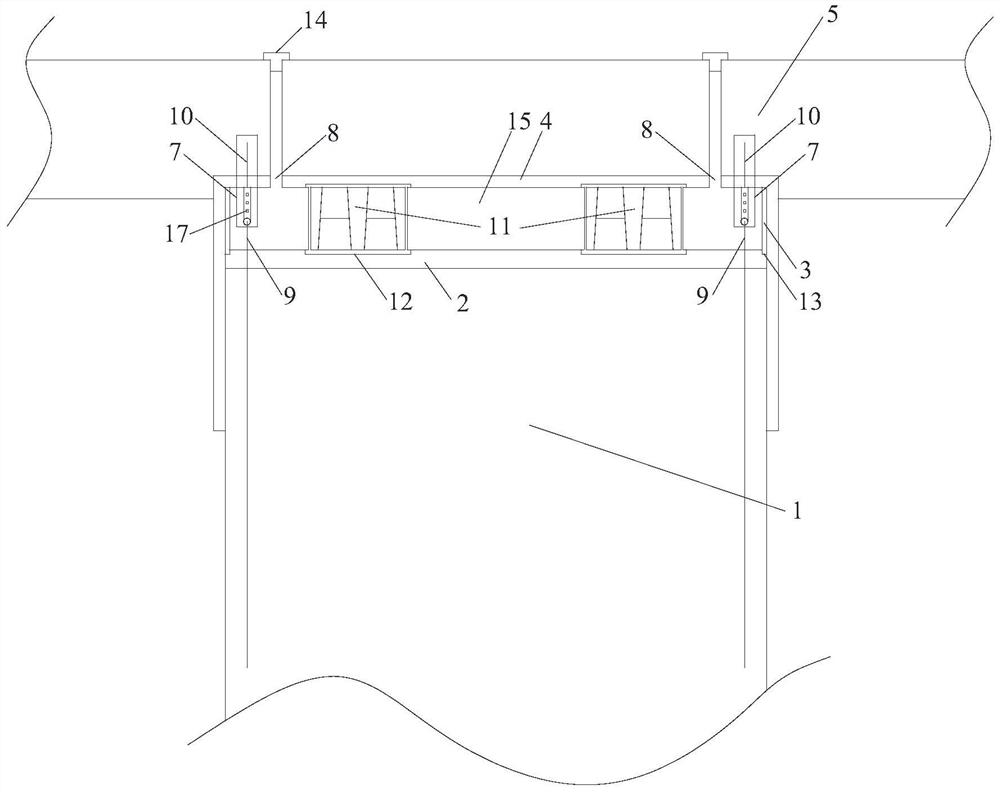

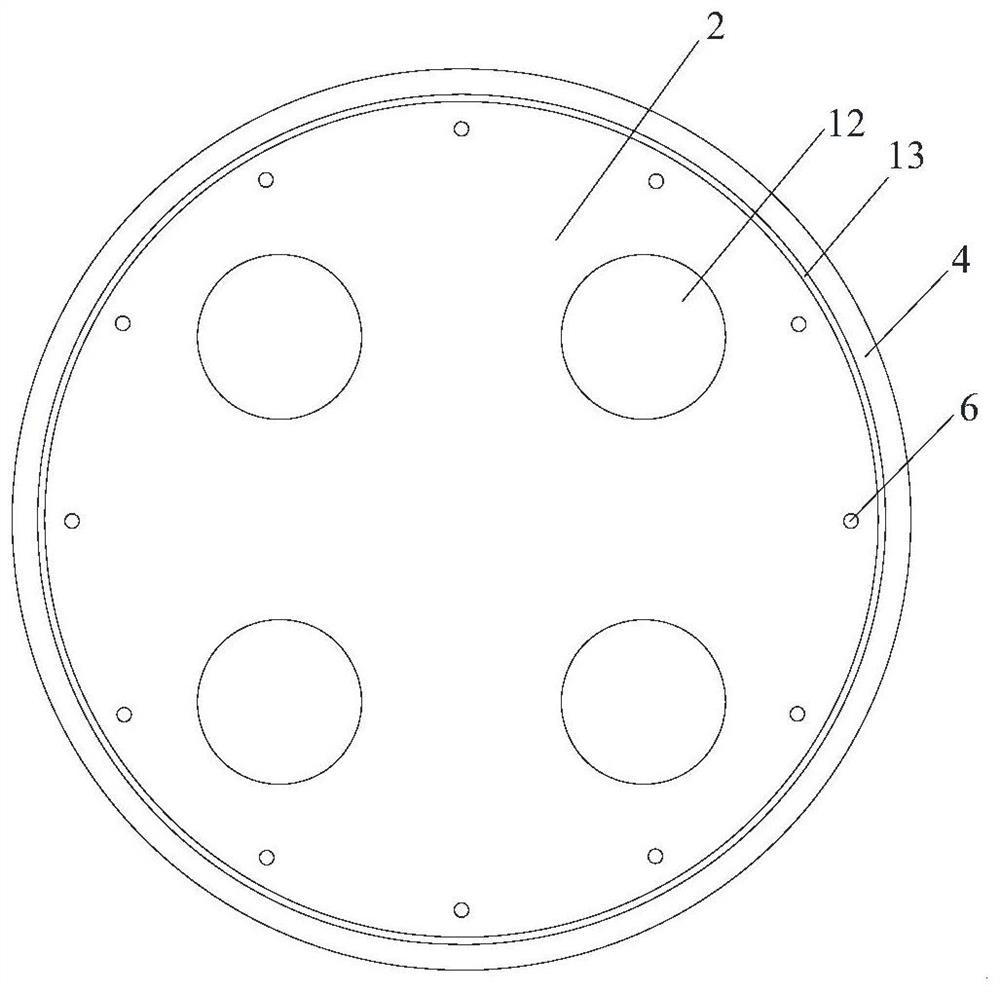

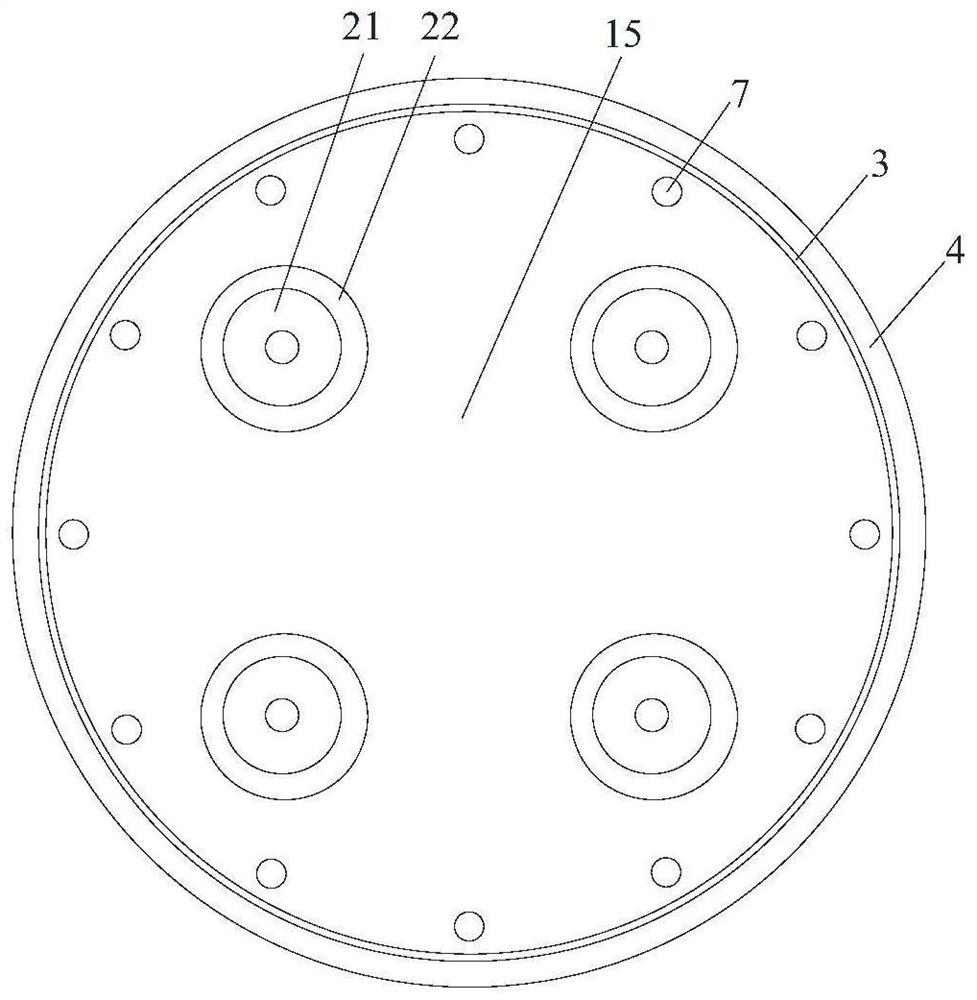

[0068] A controllable rigidity pile-raft foundation construction form of anti-pull and anti-seepage, such as figure 1 , figure 2 , image 3 As shown, it includes a base 2 fixedly installed on the top of the pile body 1, a flexible side guard plate 3, an integrated cylinder body 4, and a raft 5. The base 2 is fixedly installed on the top of the pile body 1, and the base 2 is provided with 12 A round hole 6, the bottom of the flexible side guard 3 is connected to the base 2, the integrated cylinder 4 is a circular structure with a closed top and an open bottom, and the inner wall of the top of the integrated cylinder 4 is provided with 12 A sleeve 7, a grouting hole 8, the lower part of the sleeve 7 is fixedly connected with the longitudinal reinforcement 9 in the pile body, and the steel bar 10 at the upper part of the sleeve is fixedly connected with the steel bar in the raft 5. The inner wall of the integrated cylinder 4 is fixedly connected with the outer wall of the flex...

Embodiment 2

[0099] The difference from Example 1 is that the grouting holes 8 are arranged on the same side, such as Image 6 shown.

Embodiment 3

[0101]The difference from Example 1 is that the cement-based high-strength grouting material is prepared from the following materials:

[0102] S1. Take the following raw materials and weigh them by weight: 110 parts of cement clinker, 11 parts of nano silicon oxide, 10 parts of steel fiber, 16 parts of ceramic particles, 22 parts of sodium silicate, 12 parts of slag, 20 parts of steel slag, aluminum oxide cooked 15 parts of raw materials, 20 parts of sodium nitrite, 10 parts of sodium stearate, 7 parts of phosphogypsum, 4 parts of titanium dioxide, 22 parts of river sand, 65 parts of sodium hydroxide, and 50 parts of industrial water glass;

[0103] S2. Add dry cement clinker, nano silicon oxide, steel fiber, sodium silicate, alumina clinker, sodium nitrite, sodium stearate, phosphogypsum and titanium dioxide into the pulverizer for grinding until the particle diameter is not larger than 0.1um, the mixed powder material A is obtained;

[0104] S3, adding the weighed sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com