Cordierite microcrystalline glass for silicon nitride dental ceramic facing porcelain and preparation method thereof

A technology of dental ceramics and glass-ceramics, which is applied in glass manufacturing equipment, glass pressing, glass molding, etc., can solve the problems of thermal expansion coefficient mismatch and large thermal expansion coefficient, and achieve lower thermal expansion coefficient, lower softening point and analysis The effect of crystal temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cordierite glass-ceramic for silicon nitride dental ceramic veneer, made of the following components in mass percentage:

[0032] Kaolin Kaolin76%, SiO 2 1.2%, MgO9.8%, additives 13%; additives include sintering aids and crystal nucleating agents, sintering aids consist of 5% CaCO 3 , the nucleating agent consists of 4% ZrO 2 and 4% TiO 2 Composition.

[0033] The above-mentioned preparation method for the cordierite glass-ceramic of silicon nitride dental ceramic veneer porcelain, comprises the following steps:

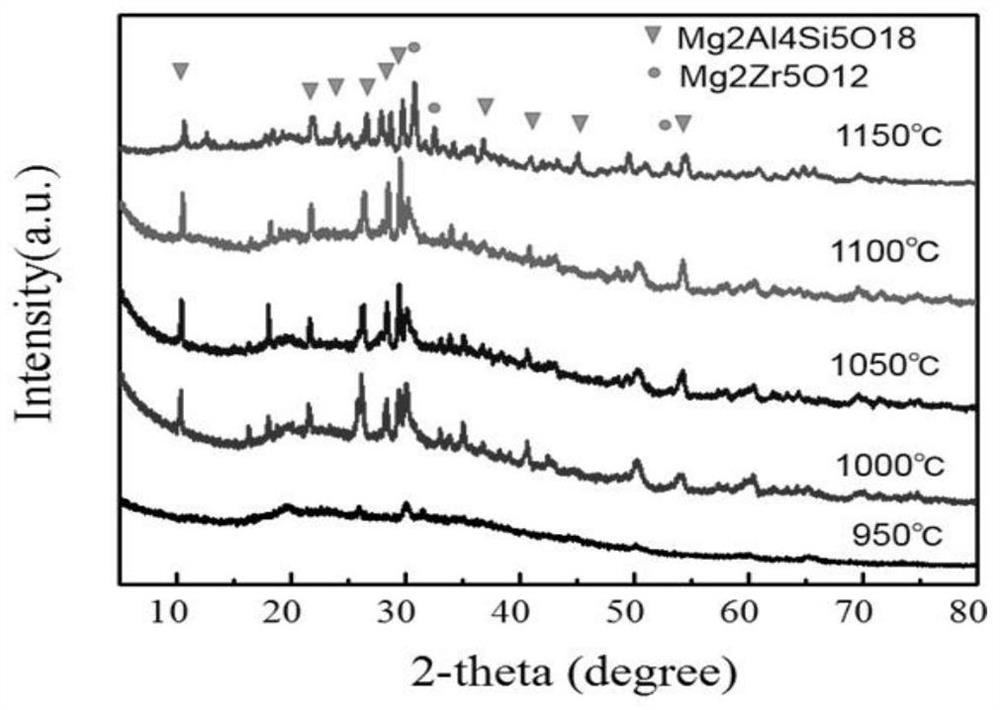

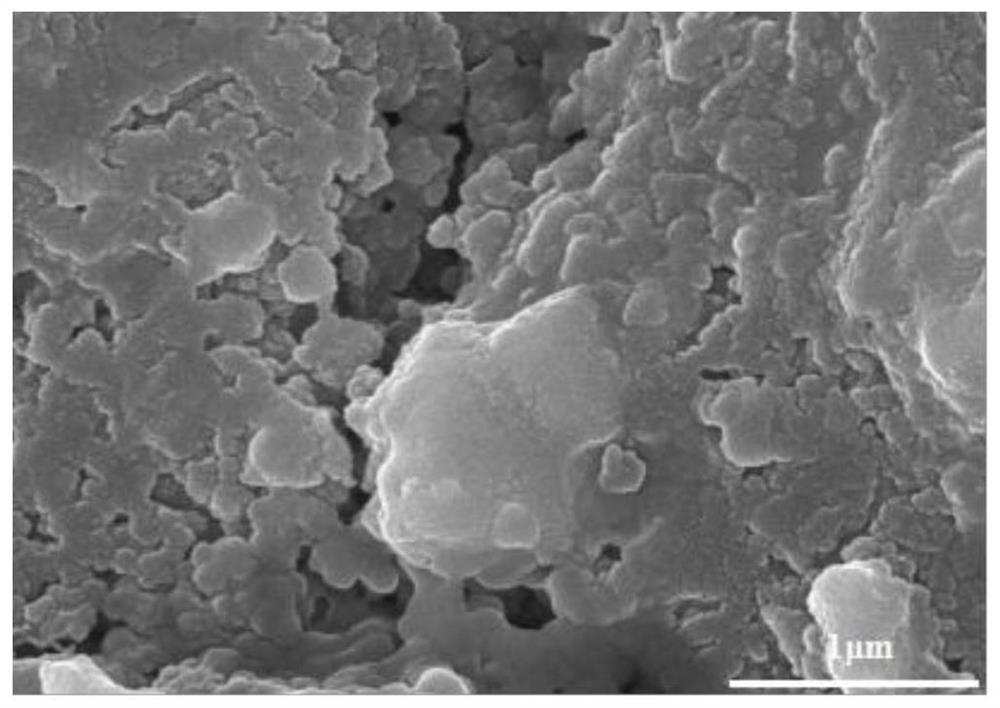

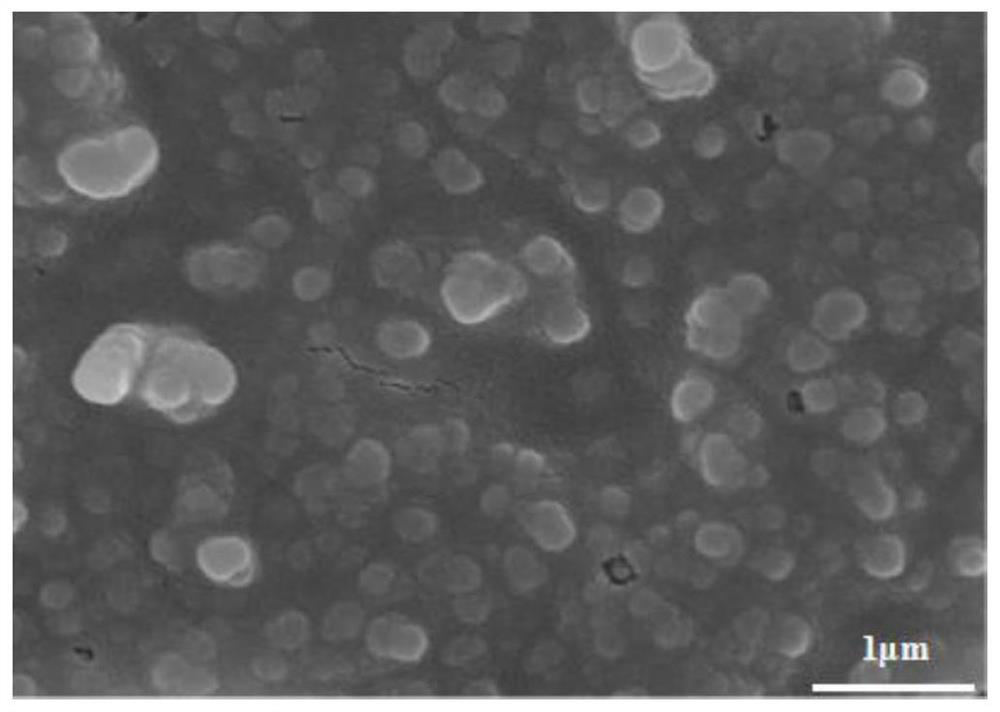

[0034]S1. Preparation of cordierite glass body: weigh kaolin, Kaolin and SiO in proportion 2 , MgO, TiO 2 , ZrO 2 and CaCO 3 , put zirconia balls of the same quality as the above-mentioned solid materials into a wide-mouth plastic bottle, add deionized water with a total mass of 5 wt% of the solid materials, and mix on a roller mill for 4 hours; Put the crucible into a frit furnace and melt at 1550°C for 2 hours. After water quenching, glass particles ...

Embodiment 2

[0037] Cordierite glass-ceramic for silicon nitride dental ceramic veneer, made of the following components in mass percentage:

[0038] Kaolin Kaolin76%, SiO 2 1.2%, MgO9.8%, additives 13%; additives include sintering aids and crystal nucleating agents, sintering aids consist of 5% CaCO 3 , the nucleating agent consists of 4% ZrO 2 and 4% TiO 2 Composition.

[0039] The above-mentioned preparation method for the cordierite glass-ceramic of silicon nitride dental ceramic veneer porcelain, comprises the following steps:

[0040] S1. Preparation of cordierite glass body: weigh kaolin, Kaolin and SiO in proportion 2 , MgO, TiO 2 , ZrO 2 and CaCO 3 , put zirconia balls of the same quality as the above-mentioned solid materials into a wide-mouth plastic bottle, add deionized water with a total mass of 5 wt% of the solid materials, and mix on a roller mill for 4 hours; Put the crucible into a frit furnace and melt at 1600°C for 2 hours. After water quenching, glass particles...

Embodiment 3

[0043] Cordierite glass-ceramic for silicon nitride dental ceramic veneer, made of the following components in mass percentage:

[0044] Kaolin Kaolin76%, SiO 2 1.2%, MgO9.8%, additives 13%; additives include sintering aids and crystal nucleating agents, sintering aids consist of 5% CaCO 3 , the nucleating agent consists of 4% ZrO 2 and 4% TiO 2 Composition.

[0045] The above-mentioned preparation method for the cordierite glass-ceramic of silicon nitride dental ceramic veneer porcelain, comprises the following steps:

[0046] S1. Preparation of cordierite glass body: weigh kaolin, Kaolin and SiO in proportion 2 , MgO, TiO 2 , ZrO 2 and CaCO 3 , put zirconia balls of the same quality as the above-mentioned solid materials into a wide-mouth plastic bottle, add deionized water with a total mass of 5 wt% of the solid materials, and mix on a roller mill for 4 hours; The crucible is put into a frit furnace and melted at 1550°C for 2.5 hours. After water quenching, glass pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com