Drag reducer and preparation method thereof

A technology of drag reducer and solvent, which is applied in the field of drag reducer and the preparation of the drag reducer, which can solve the problems of single effect of drag reducer, difficulty in achieving drag reduction effect, poor shear resistance, etc., and achieve good shale suppression The effects of high resistance, good salt resistance, and good shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

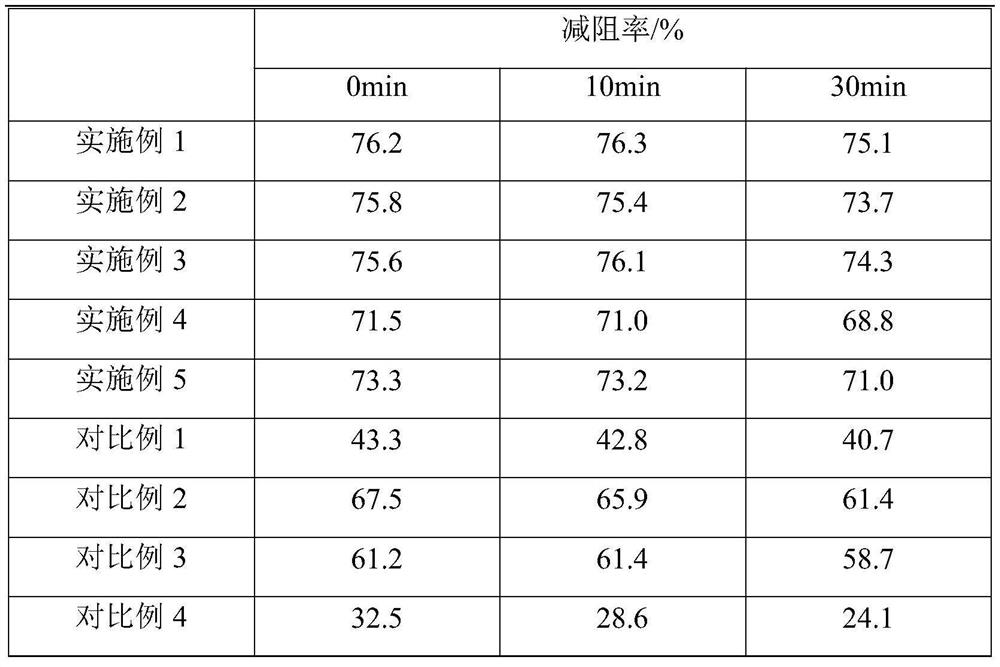

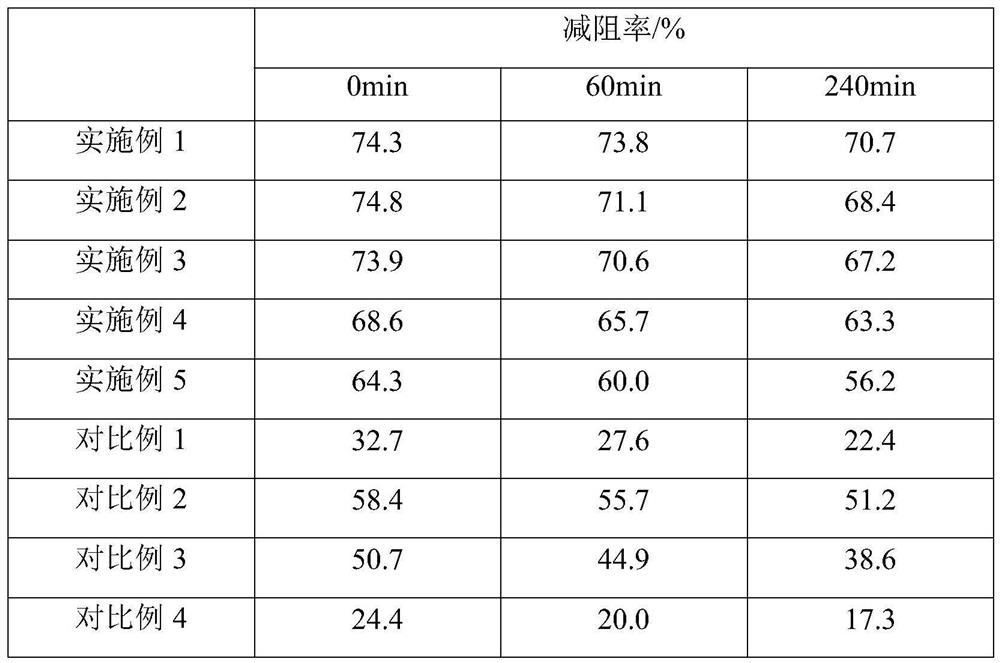

Examples

preparation example Construction

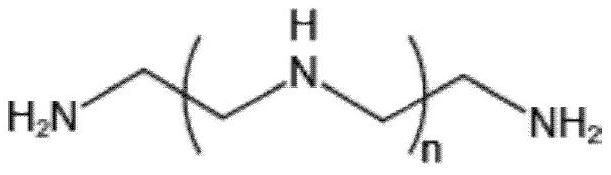

[0026] A preparation method of drag reducer, comprising the following steps:

[0027] Take 1 mole part of polyethylene polyamine and dissolve it in the first solvent, and take another 1 mole part of unsaturated quaternary ammonium salt and dissolve it in the second solvent. Add the quaternary ammonium salt solution dropwise to the polyethylene polyamine solution. After the dropwise addition, maintain the above conditions and continue the reaction for 2-4 hours. After the reaction is completed, G1 can be obtained by purification;

[0028] Take 1 mole part of G1 and dissolve it in the first solvent, and take another 1 mole part of unsaturated quaternary ammonium salt and dissolve it in the second solvent, repeat the above steps, and the number of repetitions is m-2 or m-1, wherein, m is polyvinyl The number of hydrogen atoms on the amino group in the polyamine is the branched quaternary ammonium salt G; in this step and the previous step, the unsaturated quaternary ammonium salt...

Embodiment 1

[0046] Preparation of branched quaternary ammonium salt monomer: take equimolar parts of triethylenetetramine and trimethylvinyl ammonium bromide respectively dissolved in acetone, under 70°C, nitrogen atmosphere and continuous stirring, trimethyl Vinyl ammonium bromide solution was added dropwise to triethylenetetramine solution. After the dropwise addition was completed, the aforementioned conditions were maintained for 3 hours of continuous reaction. After the reaction was completed, S1- G1;

[0047] Get S1-G1 and trimethylvinyl ammonium bromide of equimolar amount, repeat above-mentioned steps altogether 5 times, finally make branched quaternary ammonium salt S1-G; Times" means, including the initial step and subsequent repeated steps, a total of 5 times.

[0048] Take equimolar parts of S1-G and acryloyl chloride and dissolve them in tetrahydrofuran respectively. Under the condition of ice bath, blow nitrogen gas and keep stirring, add N,N-diisopropylethylamine to the S1...

Embodiment 2

[0051] Preparation of branched quaternary ammonium salt monomer: take equimolar parts of diethylenetriamine and trimethylvinylammonium bromide and dissolve them in acetone respectively. Vinyl ammonium bromide solution was added dropwise to diethylenetriamine solution. After the dropwise addition was completed, the aforementioned conditions were maintained for 3 hours of continuous reaction. After the reaction was completed, S2- G1;

[0052] Get S2-G1 and trimethylvinyl ammonium bromide of equimolar amount, repeat above-mentioned steps altogether 4 times, finally make branched quaternary ammonium salt S2-G; Times" means, including the initial step and subsequent repeated steps, a total of 4 times.

[0053] Take equimolar parts of S2-G and acryloyl chloride and dissolve them in tetrahydrofuran respectively. Under the condition of ice bath, blow nitrogen gas and keep stirring, add N,N-diisopropylethylamine to the S2-G solution, where N , the molar ratio of N-diisopropylethylami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com