Turbid liquid type drag reducer and preparation method and application thereof

A drag reducer and suspension liquid technology, applied in the suspension liquid drag reducer and its preparation, the application field of slick water fracturing fluid, can solve the operator's health injury, reduce the utilization rate, weaken the drag reduction ability, etc. problems, to achieve the effect of reducing dust pollution, convenient on-site use, and improving viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

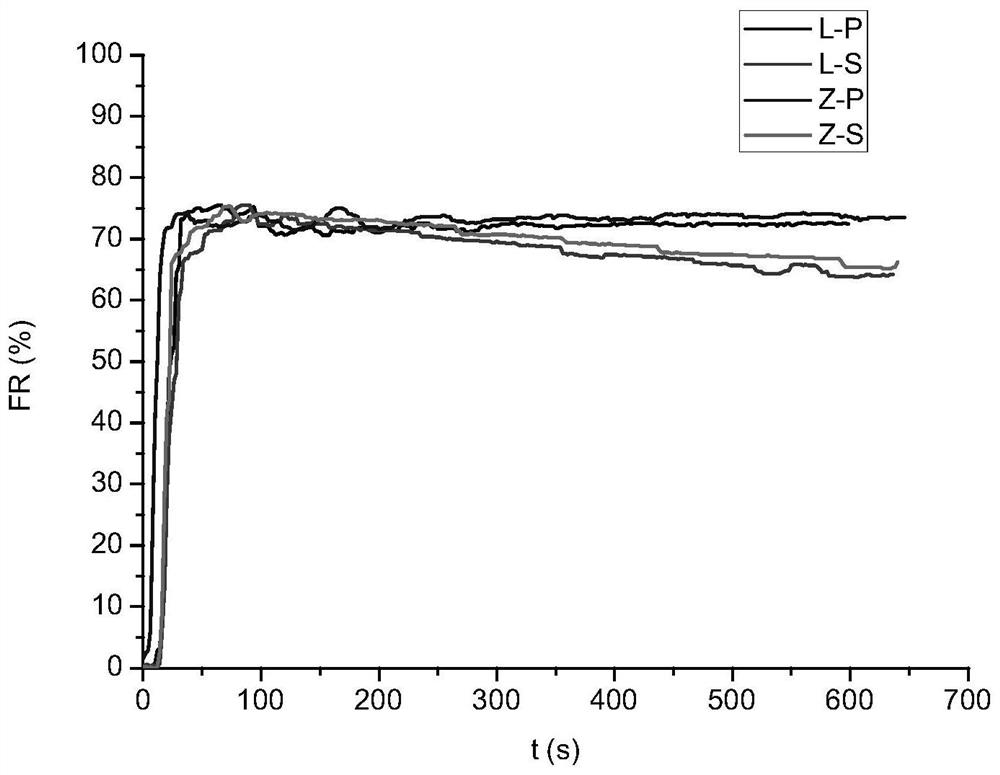

Image

Examples

Embodiment 1

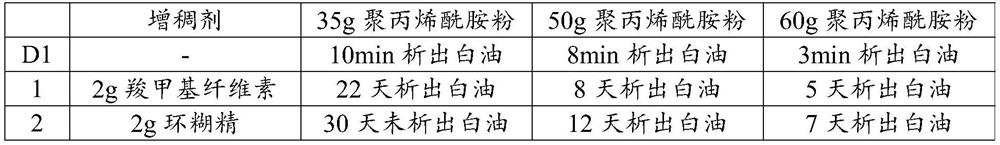

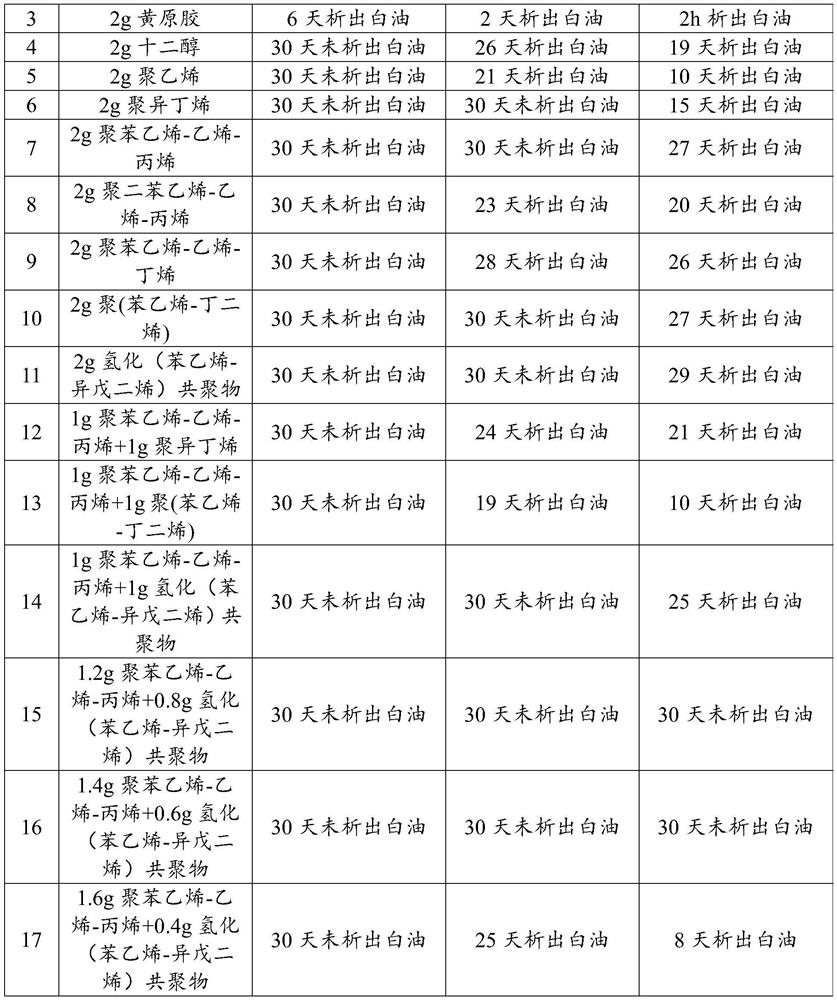

[0032]This embodiment provides a drag reducer that can be used to prepare oilfield slick water fracturing fluid, and the drag reducer is prepared from the following mass percentage of raw materials:

[0033]The molecular weight is 20 million and the particle size is 80 mesh polyacrylamide powder 50wt%, 1wt% Span60, 1wt% Tween60, thickener 2wt%, No. 5 white oil 46wt%.

[0034]The following methods are used to prepare the above-mentioned raw material components into drag reducers:

[0035]Step 1: Add 46g of No. 5 white oil to the beaker, stir under a magnetic stirrer, weigh 2g of thickener, and slowly add it to the stirred No. 5 white oil at a temperature of 55°C and a rotation speed of 700r / min. , Fully stir to make it completely dissolve, get a colorless, transparent, viscous mixture;

[0036]Step 2: Lower the temperature to 45°C, add 1g Span60 and 1g Tween60 to the mixture obtained in Step 1, and continue to stir until completely dissolved;

[0037]Step 3: Keep the temperature constant, add 50 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com