Environment-friendly ecological building material and preparation method thereof

A kind of building material and ecological technology, applied in the direction of filling slurry, etc., can solve the problems of too much formaldehyde, not enough environmental protection, and easy cracking of putty paste, and achieve the effect of improving crack resistance, adhesion, and moisture retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

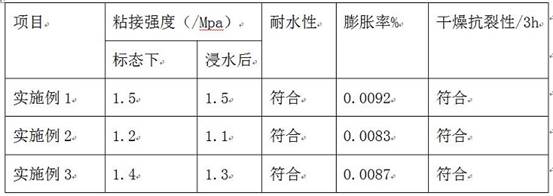

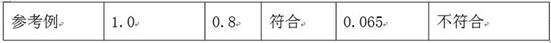

Examples

Embodiment 1

[0018] In the embodiment of the present invention, an environmentally friendly ecological building material includes 90 parts of the raw material large white powder, 80 natural rubber emulsions, 5 cellulose, 5 additions, moisture-proof agent, nano-zinc oxide 3 Series, 12 parts of the nano, 15 milk powder, 11 volcanic rocks, 65 purified water.

[0019] Further, an environmentally friendly ecological building material is prepared, including the following steps:

[0020] S1: After the nano-photovoltaic and volcanic rock abrasives, the mixture is mixed.

[0021] S2: Place a large white powder, latex powder, natural rubber emulsion, cellulose, and purified water into the dispersion, resulting in a mixture B;

[0022] S3: The mixture is mixed, and the mixture B is placed in a mixer. paste.

[0023] Further, the cellulose is mixed by carboxymethylcellulose and lignocellulose, both of which are 2: 1.

[0024] Further, the whiteflium is made of penetrate oxide.

[0025] Further, the moistu...

Embodiment 2

[0028] Preparation was prepared in accordance with Example 1, which is: an environmentally friendly ecological building material including the following weight material: 80 large white powder, 70 parts of natural rubber lotion, 12 cellulose, whitening 5 parts of the agent, 5 moisture-proof products, 3 nano-zinc oxide, 8 nano-photoprocarbon, 10 emilings, 8 volcanic rocks, purified water 60.

Embodiment 3

[0030] Preparation was carried out in accordance with Example 1, which is different from Examples 1 and Example 2: an environmentally friendly ecological building material, including the following weight material: 100 parts of large white powder, 90 natural rubber lotion, cellulose 12 5 parts of the white, 5 parts of moisture, 3 parts of nano-zinc oxide, 15 nano-optic catalysts, 20 emilings, 15 volcanic rocks, purified water 70.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com