Corrosion-resistant waterborne epoxy floor paint and preparation method thereof

A technology of epoxy floor paint and water-based epoxy resin, applied in the field of floor paint, can solve the problems of poor water resistance, corrosion resistance and anti-aging performance, improve alkali resistance, improve impact strength, and improve resistance to aging. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

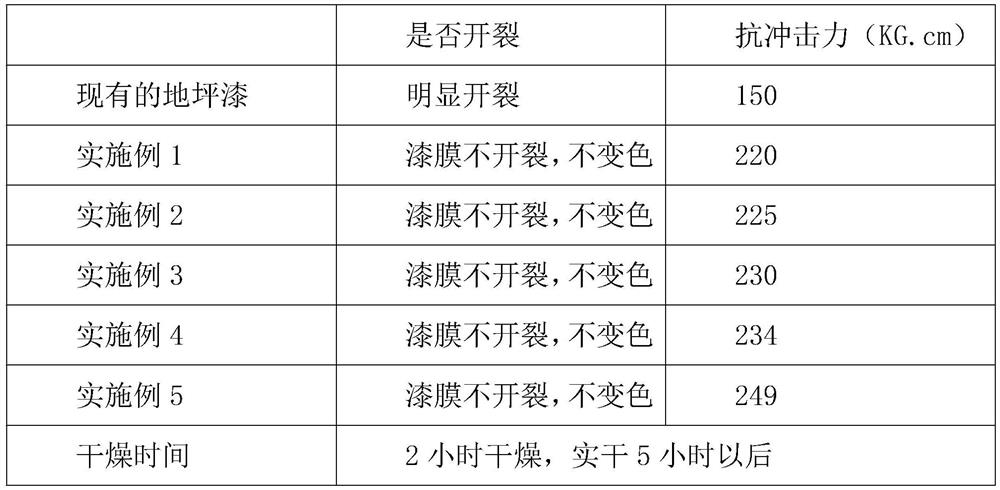

Examples

Embodiment 1

[0021] A corrosion-resistant water-based epoxy floor paint disclosed in this embodiment includes combination A and component B according to the painting ratio of 1:2, wherein the component A includes raw materials according to the following proportions : 40-45 parts of water-based epoxy resin curing agent, 60-70 parts of water, 3-5 parts of preservative, 1-5 parts of superfine light calcium carbonate powder; 3-10 parts of antistatic agent; the components B includes raw materials according to the following proportions: 30-40 parts of water-based modified epoxy resin, 10-20 parts of water-based hyperbranched resin, 10-15 parts of ultrafine light calcium carbonate powder, and 5-10 parts of modified filler , 5-8 parts of linoleic acid, 4-10 parts of graphene, 1-3 parts of preservative, 2-4 parts of dispersant, 3-5 parts of wetting agent, 4-10 parts of surfactant, 1- 9 parts, 4-8 parts of surface modifier, 2-10 parts of epoxy curing agent, 3-9 parts of water-based defoamer, 1-6 par...

Embodiment 2

[0037] A corrosion-resistant water-based epoxy floor paint disclosed in this embodiment includes combination A and component B according to the painting ratio of 1:2, wherein the component A includes raw materials according to the following proportions : 40 parts of water-based epoxy resin curing agent, 60 parts of water, 3 parts of preservatives, 1 part of superfine light calcium carbonate powder; 3 parts of antistatic agent; said component B includes raw materials according to the following proportions : 30 parts of water-based modified epoxy resin, 10 parts of water-based hyperbranched resin, 10 parts of superfine light calcium carbonate powder, 5 parts of modified filler, 5 parts of linoleic acid, 4 parts of graphene, 1 part of preservative, 2 parts of agent, 3 parts of wetting agent, 4 parts of surfactant, 1 part of reactive diluent, 4 parts of surface modifier, 2 parts of epoxy curing agent, 3 parts of water-based defoamer, 1 part of leveling agent, 4 parts of kaolin 1 p...

Embodiment 3

[0042] A corrosion-resistant water-based epoxy floor paint disclosed in this embodiment includes combination A and component B according to the painting ratio of 1:2, wherein the component A includes raw materials according to the following proportions : 42 parts of water-based epoxy resin curing agent, 62 parts of water, 4.5 parts of preservatives, 3 parts of superfine light calcium carbonate powder; 6 parts of antistatic agent; described component B includes the raw materials according to the proportioning of the following parts : 32 parts of water-based modified epoxy resin, 12 parts of water-based hyperbranched resin, 12 parts of superfine light calcium carbonate powder, 6 parts of modified filler, 6 parts of linoleic acid, 5 parts of graphene, 1.5 parts of preservative, dispersion 2.5 parts of agent, 3.5 parts of wetting agent, 6 parts of surfactant, 5 parts of reactive diluent, 4-8 parts of surface modifier, 4 parts of epoxy curing agent, 5 parts of water-based defoamer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com