Flame-retardant and fireproof sealant and preparation method thereof

A fireproof sealant and flame retardant technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of lack of flame retardant and fireproof effects, increase of flame retardants, poor flame retardant effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 flame retardant fireproof sealant

[0030] Composition in parts by weight of raw materials: 85 parts of polydimethylsiloxane; 8 parts of crosslinking agent; 1 part of catalyst; 3 parts of dispersant; 5 parts of plasticizer;

[0031] Described flame retardant is made up of zinc borate and magnesium carbonate that weight ratio is 4:1;

[0032] The preparation method of flame retardant and fireproof sealant: first put polydimethylsiloxane, dispersant and flame retardant into a high-speed mixer, and stir for 20 minutes under a vacuum of -0.06Mpa; then add a crosslinking agent and a catalyst, Stir for 150 minutes under a vacuum of -0.08Mpa to obtain the flame retardant and fireproof sealant.

Embodiment 2

[0033] The preparation of embodiment 2 flame retardant fireproof sealant

[0034] Composition in parts by weight of raw materials: 85 parts of polydimethylsiloxane; 8 parts of crosslinking agent; 1 part of catalyst; 3 parts of dispersant; 5 parts of plasticizer;

[0035] The flame retardant is a modified flame retardant, and the modified flame retardant is prepared by the following method: zinc borate and magnesium carbonate (the weight ratio of zinc borate and magnesium carbonate is 4:1) are dispersed in the volume Add N-(2-aminoethyl)-3-aminopropyltrimethoxysilane and sodium lignosulfonate to an aqueous ethanol solution with a fraction of 50% and stir evenly; then grind at a temperature of 50° C. for 8 hours; After the grinding is finished, the grinding slurry is dried to obtain the modified flame retardant; wherein, the total weight of zinc borate and magnesium carbonate and ethanol aqueous solution and N-(2-aminoethyl)-3-aminopropyltrimethyl The dosage ratio of oxysilane ...

experiment example 1

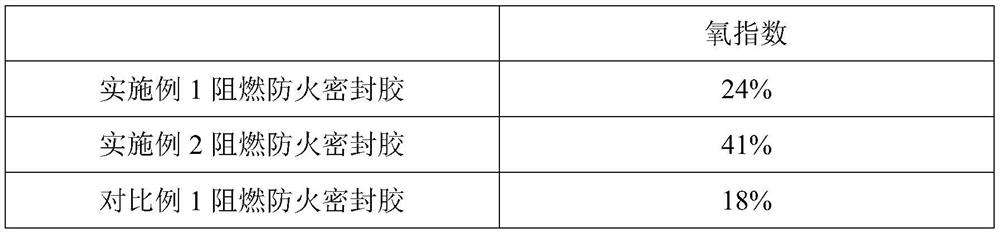

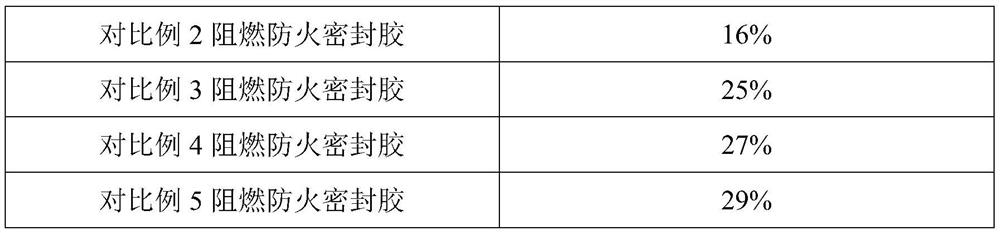

[0063] The flame-retardant and fire-proof sealants prepared in Examples 1 and 2 and Comparative Examples 1 to 5 were made into a sample strip with a length of 100mm, a width of 6mm, and a thickness of 3mm; refer to GB / T 2406.2-2009 to test the flame-retardant and fire-proof sealant sample in The minimum oxygen concentration (oxygen index) required to maintain balanced combustion in the oxygen-nitrogen mixed flow; the higher the oxygen index, the better the fire and flame retardant effect; the test results are shown in Table 1.

[0064] Table 1. Fireproof effect test of flame retardant and fireproof sealant

[0065]

[0066]

[0067] As can be seen from the test data in Table 1, the flame retardant and fireproof effect of the flame retardant and fireproof sealant of embodiment 1 is obviously better than that of comparative examples 1 and 2, which shows that the preparation of flame retardant and fireproof sealant with polydimethylsiloxane is a raw material. Glue, adding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com