Preparation method of high-performance neodymium-iron-boron permanent magnet

A neodymium-iron-boron, permanent magnet technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of affecting magnetic properties, reducing the diffusion efficiency of diffusion channels, and unable to carry out corresponding processing, etc. Improved performance, reduced carbon content, easy diffusion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

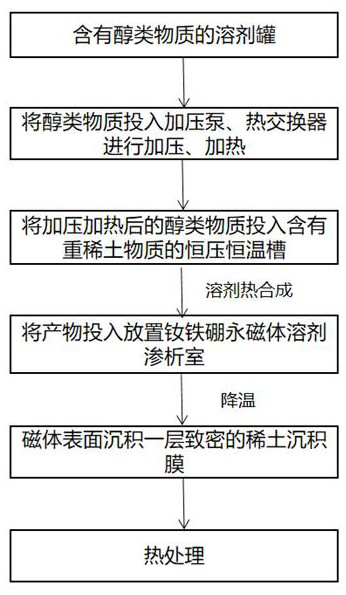

[0031] A method for preparing a high-performance NdFeB permanent magnet, the steps of the preparation method are:

[0032] S1: Take the NdFeB permanent magnet raw material with a specification of 5.2mm*5.2mm*2mm, slice the NdFeB permanent magnet raw material, remove oil, clean and dry it, and then put it into a vacuumized solvent dialysis chamber;

[0033] S2: Put the heavy rare earth material mixed with anhydrous dysprosium acetate and anhydrous terbium nitrate at a ratio of 1:1 into a constant temperature and pressure tank;

[0034] S3: After the absolute ethanol in the solvent tank is pressurized to 6.32MPa through a booster pump and a heat exchanger, heated to 180°C, it flows through a constant temperature and pressure tank, and the solvothermal synthesis method is used to decompose the ethanol in the constant temperature and pressure tank. The heavy rare earth is extracted, the reaction time is 8 hours, and then flows into the solvent dialysis chamber;

[0035] S4: Cool ...

Embodiment 2

[0043] A method for preparing a high-performance NdFeB permanent magnet, the steps of the preparation method are:

[0044] S1: Take a sintered and untempered NdFeB permanent magnet with a size of 5.2mm*5.2mm*2mm, slice the NdFeB permanent magnet raw material, remove oil, clean and dry it, and put it into a vacuumized solvent dialysis chamber;

[0045] S2: Put the heavy rare earth material mixed with anhydrous dysprosium oxide and anhydrous terbium oxide at a ratio of 1:1 into a constant temperature and pressure tank;

[0046] S3: After the absolute ethanol in the solvent tank is pressurized to 6.35MPa through a booster pump and a heat exchanger, heated to 243.1°C, it flows through a constant temperature and pressure tank, and the heavy alcohol in the constant temperature and pressure tank is purified by solvothermal synthesis. The rare earth is extracted, the reaction time is 8 hours, and then flows into the solvent dialysis chamber;

[0047] S4: Cool down the solvent dialysi...

Embodiment 3

[0055] A method for preparing a high-performance NdFeB permanent magnet, the steps of the preparation method are:

[0056] S1: Take a sintered and untempered NdFeB permanent magnet with a size of 5.2mm*5.2mm*2mm, slice the NdFeB permanent magnet raw material, remove oil, clean and dry it, and put it into a vacuumized solvent dialysis chamber;

[0057] S2: Put the heavy rare earth material containing anhydrous dysprosium oxide into the constant temperature and pressure tank;

[0058] S3: The anhydrous butanol in the solvent tank is pressurized to 4.41MPa through a booster pump and a heat exchanger, heated to 289°C, and then flows through a constant temperature and pressure tank, and the solvothermal synthesis method is used to synthesize the anhydrous butanol in the constant temperature and pressure tank. The heavy rare earth is extracted, the reaction time is 8 hours, and then flows into the solvent dialysis chamber;

[0059] S4: Cool down the solvent dialysis chamber at a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com