MW (megawatt) grade cogeneration fuel cell power station

A fuel cell and combined heat and power technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve the lack of systematic water resources management, lack of waste heat utilization, and inability to adapt to MW-level combined heat and power fuel cell power station projects Application and other issues to achieve the effect of reducing gas supply costs, reducing overall costs, and improving gas supply quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

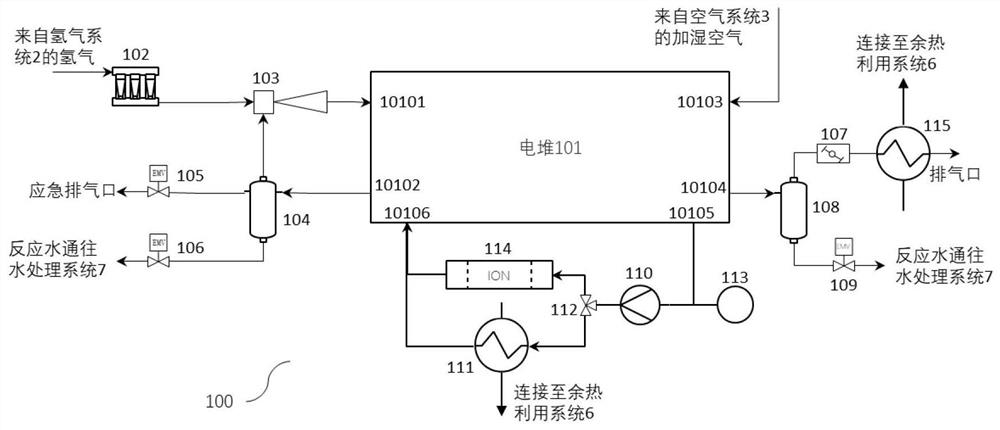

[0060] Embodiment 1: A MW-level combined heat and power fuel cell power station.

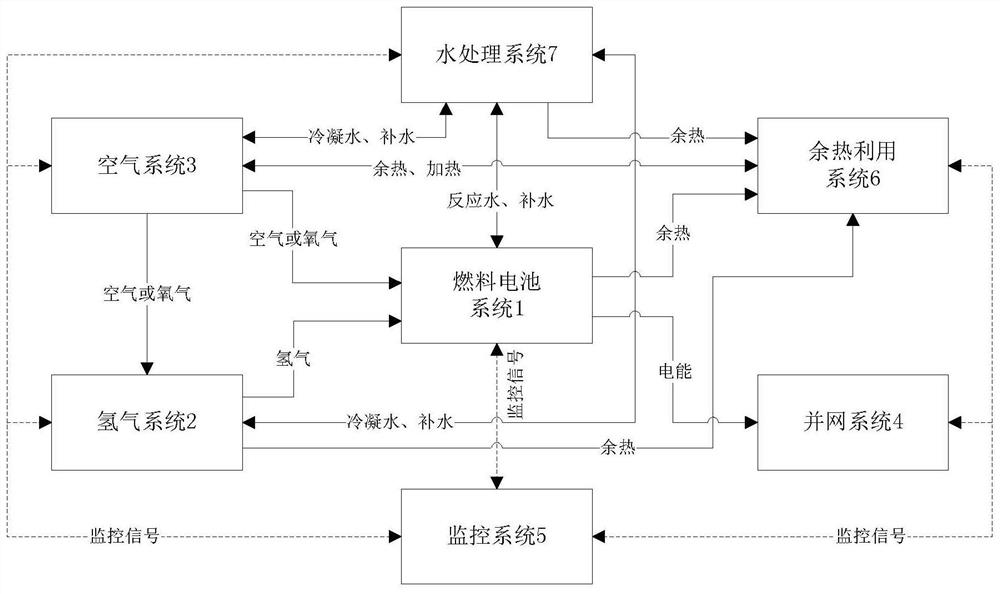

[0061] like figure 1 As shown, the MW-level combined heat and power fuel cell power plant of this embodiment includes a fuel cell system 1 , a hydrogen system 2 , an air system 3 , a grid-connected system 4 , a monitoring system 5 , a waste heat utilization system 6 and a water treatment system 7 . Hydrogen system 2 adopts methanol reforming hydrogen production technology to provide high-purity hydrogen for fuel cell system 1; air system 3 provides air or oxygen for fuel cell system 1 and hydrogen system 2, which is used to provide the air side reaction of fuel cell system 1 Gas, providing high-pressure gas for the high-pressure catalytic combustion reaction of the hydrogen system; the grid-connected system 4 is used to transmit electric energy to the grid, and the monitoring system 5 is used to monitor and control the operating parameters of the power station; the waste heat utilization system ...

Embodiment 2

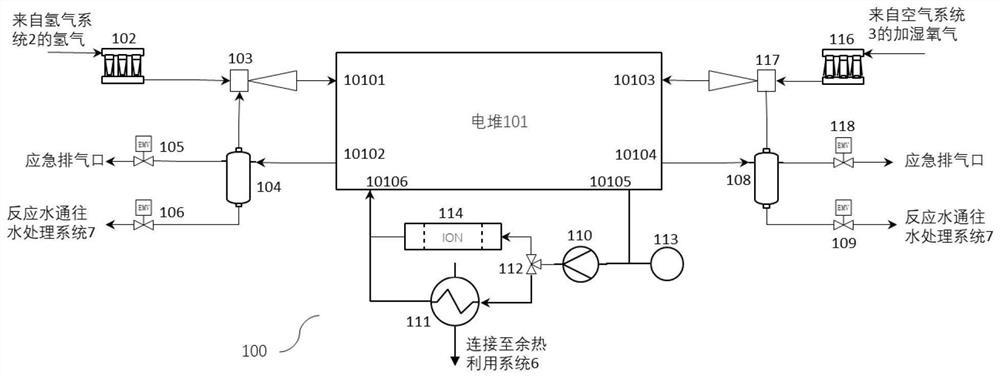

[0086] Embodiment 2: A MW-level combined heat and power fuel cell power station.

[0087] The difference between this embodiment and Embodiment 1 is, as Figure 9 As shown, multiple heat exchangers are connected in series-parallel combination. Specifically, after the first heat exchanger 111 and the second heat exchanger 115 of the fuel cell system 1 are connected in parallel, they are sequentially connected with the fifth heat exchanger 309 and the first cooler 304 of the air system 3 and the fourth heat exchanger 304 of the hydrogen system 2. The heat exchanger 205 is connected in series to the hot-side pipeline 603 and the cold-side pipeline 602 . The above connection mode is designed according to the working temperature of the system where each heat exchanger is located, that is, the circulating water flows through the first heat exchanger 111 and the second heat exchanger 115 with a temperature of about 80°C on the hot side to cool the electric stack 101, and then flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com