Synthesis method of polycarboxylate superplasticizer by taking polyether macromonomer as raw material

A technology of polyether macromonomer and synthesis method, which is applied in the synthesis of polycarboxylate water reducer and the synthesis field of polycarboxylate water reducer. Problems such as high heat release rate can achieve the effect of improving frost resistance and early strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

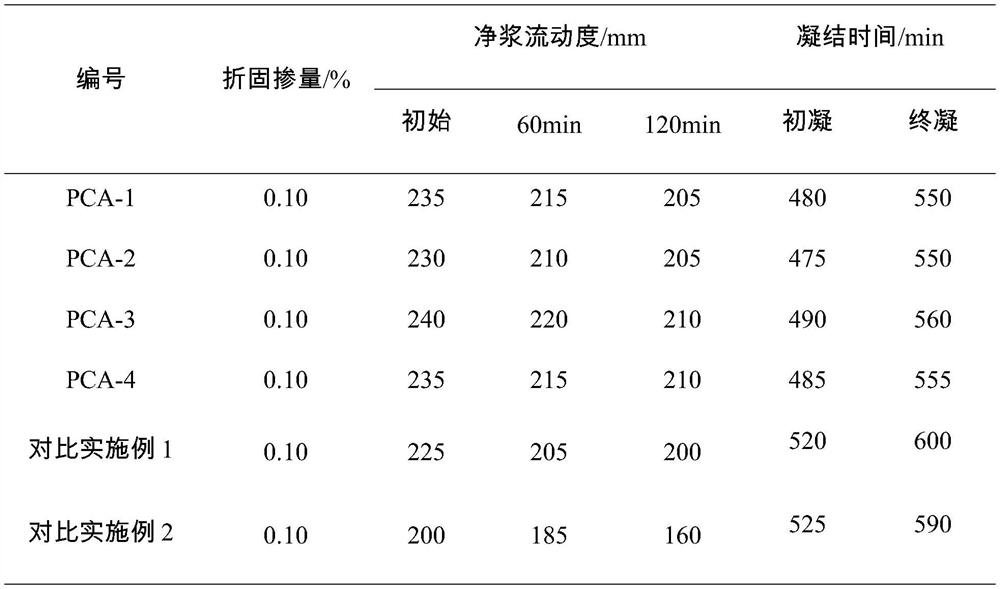

Examples

preparation example Construction

[0031] A kind of synthetic method of the polycarboxylate water-reducer taking polyether macromonomer as raw material, comprises the following steps,

[0032] S1. Preparation of dripping liquid: prepare unsaturated carboxylic acid, freezing point lowering additive, water, and cooling agent into dripping liquid A according to a certain mass ratio; chain transfer agent, reducing agent, freezing point lowering additive, water, and cooling agent The mass ratio is prepared into dripping solution B;

[0033] The consumption of freezing point depressing additive and cooling agent is the same in the above-mentioned dripping solution A and dripping solution B preparation process, and the mass ratio of described unsaturated carboxylic acid and the polyether macromonomer containing terminal ethyleneoxy structure is 1:(5 ~10), the prepared water reducer has better performance characteristics.

[0034]The consumption ratio of each substance in the preparation process of the dripping soluti...

Embodiment 1

[0049] Dropping solution A: Weigh 20.0 parts of acrylic acid, add 33.1 parts of water, stir well, add 1.14 parts of sodium nitrate as a freezing point lowering additive, and 2.86 parts of cooling agent ice cubes, fully stir and dissolve, and the preparation of dropping solution A is completed;

[0050] Dropping solution B: Weigh 0.24 parts of mercaptopropionic acid and 0.12 parts of L-ascorbic acid, add water and dilute to an aqueous solution with a mass concentration of 2%. Add 1.14 parts of sodium nitrate additive for lowering the freezing point, 2.86 parts of ice cubes for cooling agent, fully stir and dissolve, and the preparation of dripping liquid B is completed;

[0051] Weigh 100 parts of EPEG-5000 polyether macromonomer in a reaction device, add 150 parts of water, and prepare an aqueous solution with a mass concentration of 40%. Weigh 0.60 parts of 30% solid-containing hydrogen peroxide and add it to the reaction device, and the preparation of the primer solution is ...

Embodiment 2

[0053] Dropping solution A: Weigh 9.3 parts of methacrylic acid, 5.0 parts of itaconic anhydride, add 16.1 parts of water, stir well, add 1.79 parts of calcium nitrite for lowering the freezing point, and 3.56 parts of ammonium nitrate as a cooling agent, fully stir to dissolve, drop The preparation of liquid A is completed;

[0054] Dropping solution B: Weigh 0.91 part of thioglycolic acid and 0.34 part of white block, add water and dilute to an aqueous solution with a mass concentration of 5%. Add 1.79 parts of calcium nitrite to lower the freezing point additive, 3.56 parts of ammonium nitrate as a cooling agent, fully stir and dissolve, and the preparation of dripping liquid B is completed;

[0055] Weigh 100 parts of VPEG-3000 polyether macromonomer in a reaction device, add 66.7 parts of water, and prepare an aqueous solution with a mass concentration of 60%. Weigh 0.91 parts of sodium persulfate and add it to the reaction device, and the preparation of the primer solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com