Glass fiber reinforced PMMA pultruded profile and manufacturing method thereof

A pultrusion profile and glass fiber technology, applied in the field of glass fiber reinforced PMMA pultrusion profile and its manufacturing, can solve the problems of non-environmental protection, difficult recycling, high cost and other problems in the production process, and achieve excellent UV resistance, good corrosion resistance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of glass fiber reinforced PMMA pultrusion profile of the present embodiment, the raw material used of this profile comprises the MMA prefabricated material of 25% by weight and the glass fiber of 70% by weight, wherein

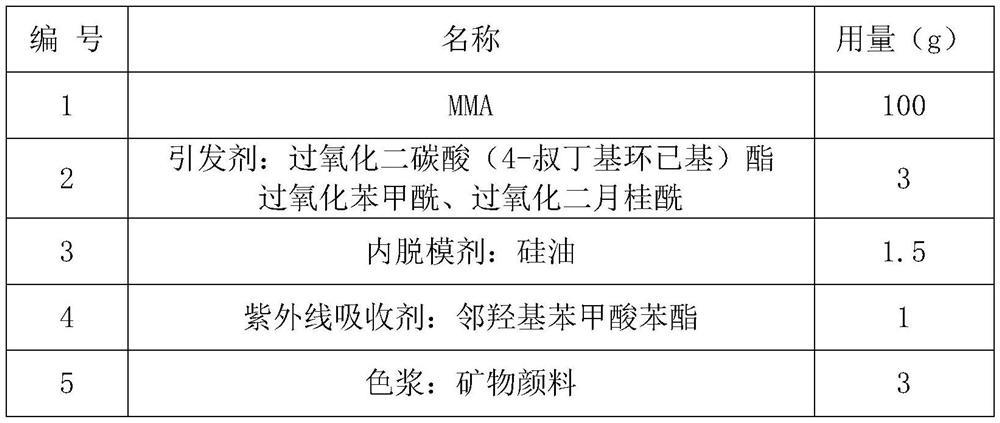

[0048] The MMA prefab configuration is:

[0049]

[0050] The glass fiber is a high-strength corrosion-resistant HCR glass fiber produced by Chongqing International Composite Materials Co., Ltd., which is a commercially available product.

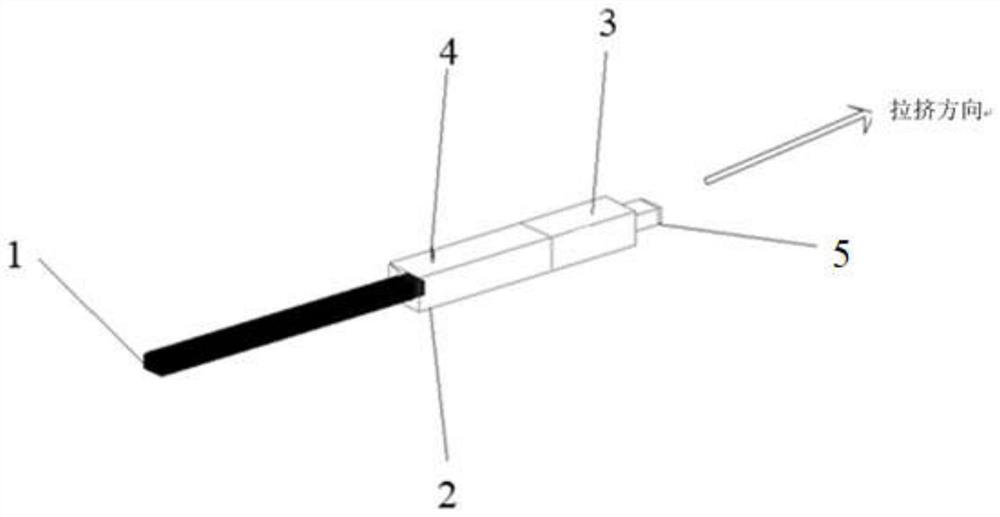

[0051] For specific manufacturing methods, see figure 1 ,

[0052] (1) The glass fiber 1 is drawn into the mold cavity of the pre-polymerization zone 2 of the mold, and the mold temperature of the pre-polymerization zone 2 is set between 25°C and 100°C;

[0053] (2) Methyl methacrylate preform is injected into the mold cavity of prepolymerization zone 2 from the prefabricated material injection port 4 by a glue injection machine, and the glass fiber 1 is soaked in the mold cavity of prepolymerization zone 2...

Embodiment 2

[0059] A kind of glass fiber reinforced PMMA pultrusion profile of the present embodiment, the raw material used of this profile comprises the MMA prefabricated material of 15% by weight and the glass fiber of 85% by weight, wherein

[0060] The MMA prefab configuration is:

[0061]

[0062]

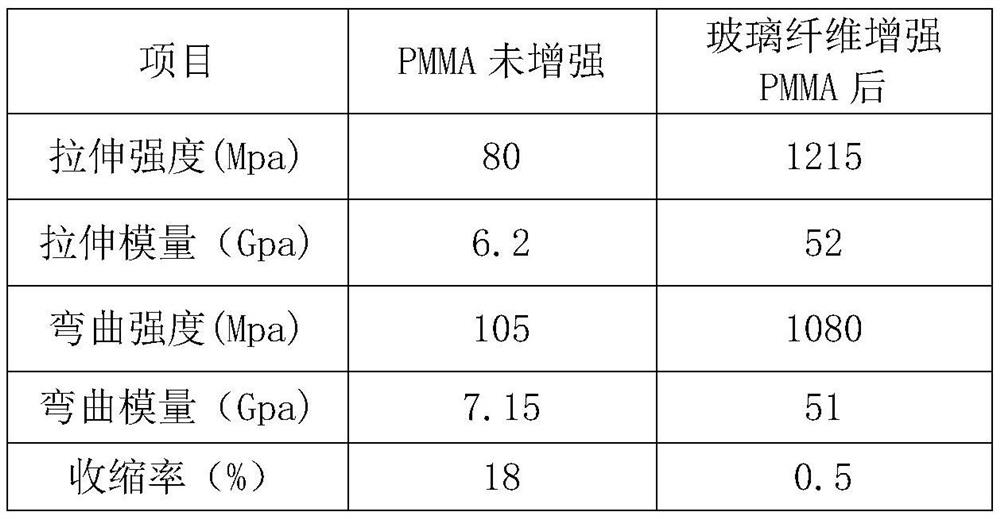

[0063] After testing, the mechanical properties of the glass fiber reinforced PMMA pultruded profile obtained in this embodiment are as follows:

[0064]

[0065] After artificially accelerated weather aging test by ultraviolet irradiation, the expected service life can reach more than 30 years.

Embodiment 3

[0067] A kind of glass fiber reinforced PMMA pultruded profile of the present embodiment, the raw material used for this profile comprises the MMA prefabricated material of 45% by weight and the glass fiber of 60% by weight, wherein, the MMA prefabricated material is configured as:

[0068]

[0069] After testing, the mechanical properties of the glass fiber reinforced PMMA pultruded profile obtained in this embodiment are as follows:

[0070]

[0071] After artificially accelerated weather aging test by ultraviolet irradiation, the expected service life can reach more than 30 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com