TSV-combined electroplating pretreatment process method

A technology of electroplating pretreatment and process method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as copper seed layer electroplating defects, and achieve the effects of easy control, large process window, and reduced scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

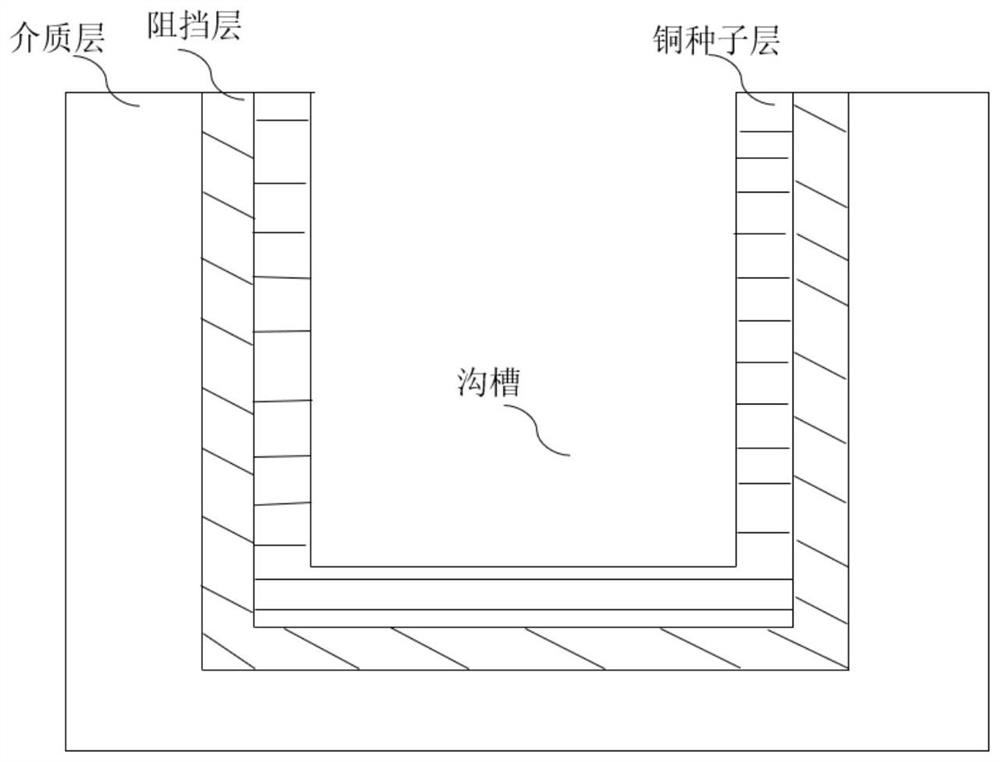

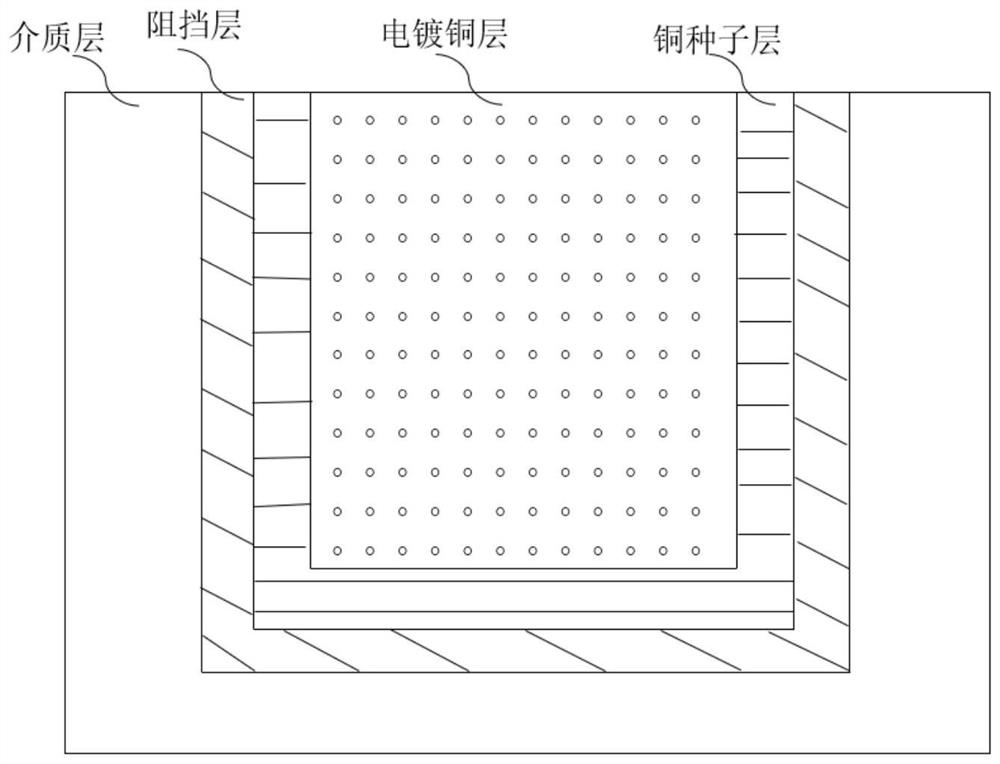

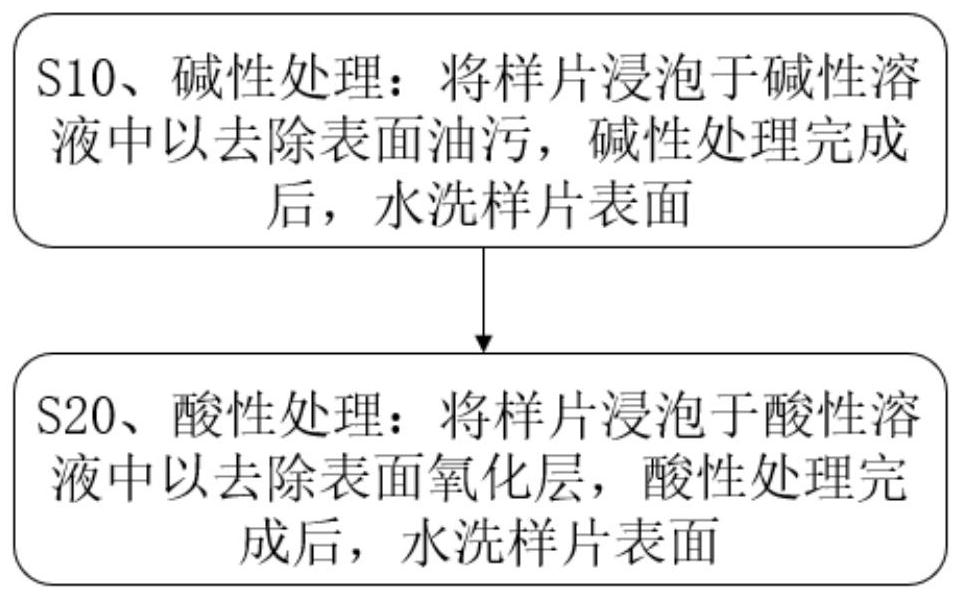

[0049] like image 3 As shown, this embodiment provides a method for combining TSV electroplating pretreatment process, including the following steps:

[0050] S10. Alkaline treatment: soak the sample in alkaline solution to remove surface oil, after the alkaline treatment is completed, wash the surface of the sample;

[0051] S20. Acid treatment: soak the sample in an acidic solution to remove the surface oxide layer, and wash the surface of the sample with water after the acid treatment is completed.

[0052] In the above steps, step S10, that is, the alkaline treatment step, can effectively remove the oil stain on the surface of the sample, and make the surface of the sample and the acidic electroplating solution more bonded; step S20, that is, the acidic treatment step, can effectively remove the oxide layer on the surface of the sample, thereby Avoid the electroplating defect problem caused by the oxidation problem in the wafer electroplating, and reduce the scrapping of...

no. 2 example

[0055] like Figure 4 As shown, this embodiment provides a method for combining TSV electroplating pretreatment process, including the following steps:

[0056] S10. Alkaline treatment: Soak the sample in an alkaline solution to remove surface oil. The alkaline solution is KOH solution or NaOH solution. The pH value of the alkaline solution is between 7 and 13. After the alkaline treatment is completed, wash with water sample surface;

[0057] S20. Acid treatment: soak the sample in an acid solution to remove the surface oxide layer. The acid solution is a mixture of 0.3% to 5% sulfuric acid and hydrogen peroxide. After the acid treatment, the surface of the sample is washed with water.

[0058] The important difference between this embodiment and the first embodiment is that this embodiment specifically defines that the alkaline solution used is KOH solution or NaOH solution, and the acidic solution is a mixture of sulfuric acid and hydrogen peroxide, wherein KOH solution or...

no. 3 example

[0060] like Figure 5 As shown, this embodiment provides a method for combining TSV electroplating pretreatment process, including the following steps:

[0061] S10. Alkaline treatment: soak the sample in an alkaline solution under vacuum conditions to remove surface oil, and wash the surface of the sample with water after the alkaline treatment is completed;

[0062] S20. Acid treatment: soak the sample in an acidic solution under vacuum conditions to remove the surface oxide layer, and wash the surface of the sample with water after the acid treatment is completed.

[0063] The difference between this embodiment and the first embodiment is that this embodiment limits the alkali treatment and acid treatment steps under vacuum conditions, thus having the beneficial effect that the vacuum conditions can extract the air in the sample groove, Therefore, it is beneficial for the alkaline solution and the acidic solution to enter into it, thereby achieving the purpose that the alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com