High-precision reference generation method and system

A production method and high-precision technology, which is applied in the direction of control/regulation system, instrument, and electric variable adjustment, to achieve high precision, low load regulation rate, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

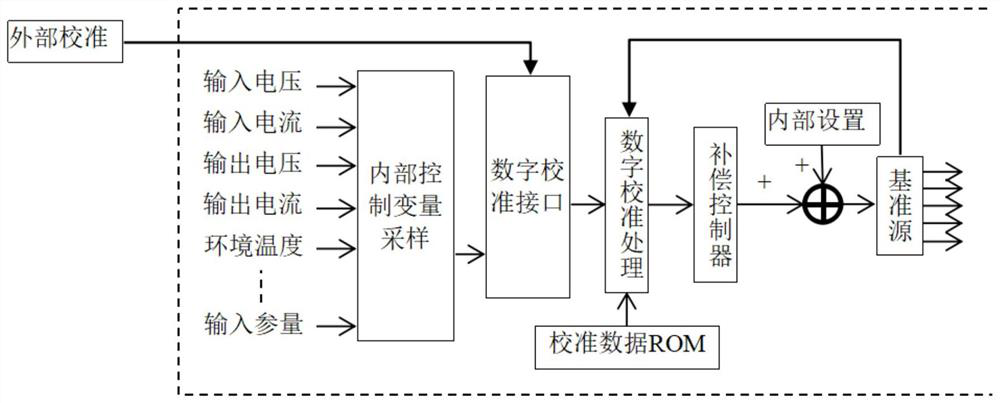

[0052] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5a , Figure 5b , Figure 6a , Figure 6b , Figure 7 , Figure 10 , which looks like this:

[0053] The high-precision reference source in this embodiment includes: an internally set conventional reference source, internal control variable sampling, digital calibration interface, digital calibration processing, calibration data and a compensation controller.

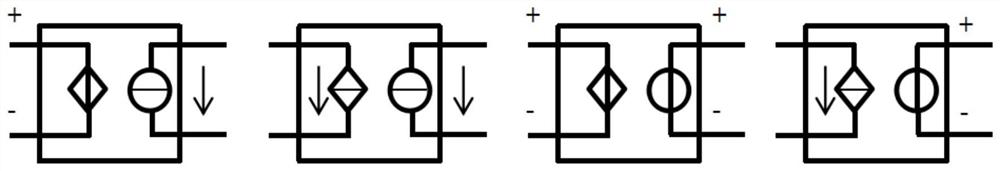

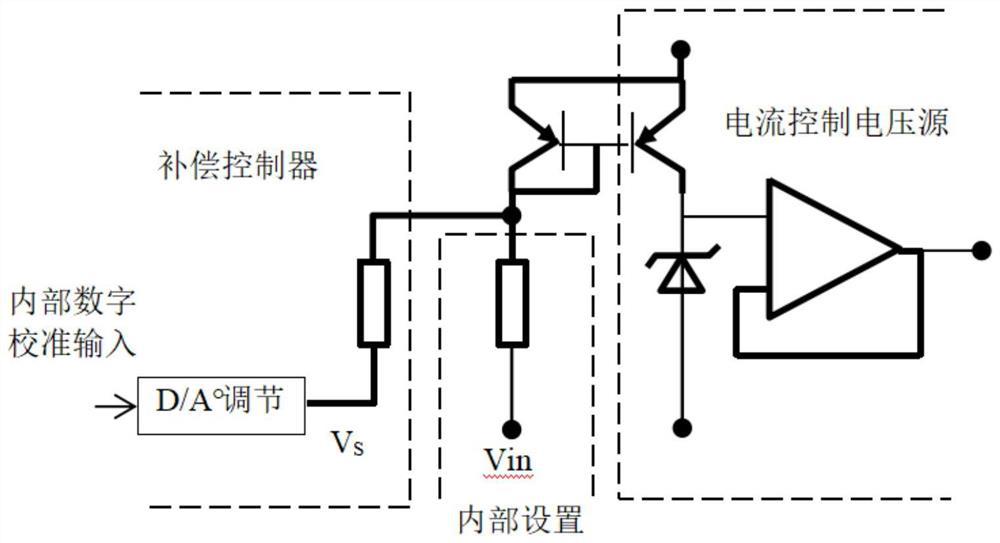

[0054] General reference source set internally. Divided into voltage-controlled current source, current-controlled current source, voltage-controlled voltage source, current-controlled voltage source, see figure 2 . The analog reference can be composed of triode, Zener tube, MOS, and corresponding peripheral resistors. The digital reference can be directly generated by D / A conversion, please refer to Figure 4 . By setting the current and voltage control source internally, the output circuit and voltage source can be adjusted. The internal ...

Embodiment 2

[0063] The digital calibration interface adopts the SPI interface, which is responsible for receiving digital signals from the temperature sensing part, the voltage measurement part at the load, the current measurement part at the load, and the power supply voltage measurement part, and sending them to the compensation controller. For the temperature and current sampling circuit, please refer to Figure 8 shown. The external calibration interface is an analog interface, which is not limited by the working conditions of the chip.

[0064] The compensation controller includes a central processing unit CPU with data processing capabilities, data memory RAM, program memory ROM, various I / O ports and interrupt systems, timers / counters, the compensation controller collects communication traffic from the digital calibration interface, and performs Decoding analysis, calculate the actual temperature value, load voltage value, load current value and power supply voltage value in the co...

Embodiment 3

[0071] see Figure 13 , Figure 13 A schematic diagram of a high-precision reference generation system module provided by the embodiment of the present invention is as follows:

[0072] The high-precision reference source module 10 is used to adjust the internal reference source and / or bias source according to the method of the digital circuit, so as to realize the high-precision reference or bias, internally set internal control variable sampling, digital calibration interface, and digital calibration processor , data memory, compensation controller, digital calibration processing;

[0073] Adding the calibration signal module 20 of the analog reference, which is used to externally add the calibration signal of the analog reference to the digital calibration interface, so as to realize the high-precision reference or offset under the required working conditions;

[0074] The calibration and compensation module 30 is used to correct the internal reference under various worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com