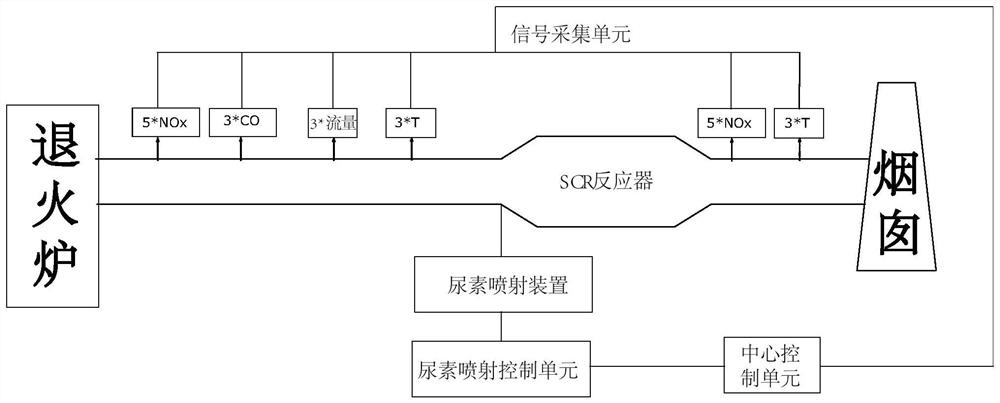

Intelligent control system for flue gas denitration of annealing furnace

An intelligent control system and annealing furnace technology, applied in the field of flue gas denitrification, can solve the problems of poor effect and high labor cost, and achieve the effect of fast response and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

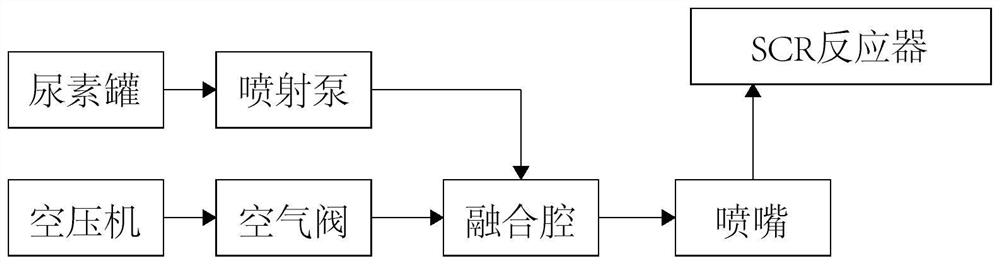

Method used

Image

Examples

Embodiment 1

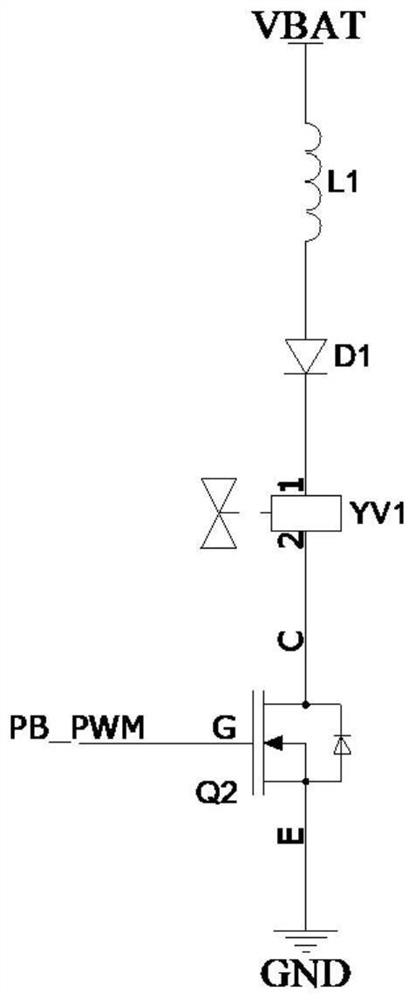

[0029] Example 1, such as image 3 as shown,

[0030] The urea injection control unit includes a nozzle control circuit, the nozzle control circuit includes a diode D1 and a transistor Q2, the gate of the transistor Q2 is connected to the PB_PWM signal output by the central control unit, the emitter of the transistor Q2 is grounded, and the collector of the transistor Q2 is connected in series with the nozzle electromagnetic The cathode of the diode D1 is connected behind the valve YV1, and the anode of the diode D1 is connected to the power supply VBAT through the inductor L1.

[0031] The urea nozzle is a component that realizes the precise injection of urea solution. The main part of the nozzle is a solenoid valve, so the control of the nozzle by this system is essentially the control of the solenoid valve. Its main function is to atomize and spray the urea water mixed with air. The principle is to control the opening and closing of the solenoid valve of the nozzle by usin...

Embodiment 2

[0033] Example 2, such as Figure 4 as shown,

[0034]On the basis of Embodiment 1, the nozzle control circuit also includes a pulse width modulation chip U1, a diode D2, a resistor R1, a resistor R2, a capacitor C1, and a transistor Q1. The input pin Vi of the pulse width modulation chip U1 is connected to the power supply BAT, and the pulse The voltage feedback pin VFB of the width modulation chip U1 is connected to the cathode of the diode D2, the anode of the diode D2 is connected to the PB_CUT signal output by the central control unit, the output terminal OUT of the pulse width modulation chip U1 is connected to the gate of the transistor Q1 through the resistor R3, and the transistor Q1 The emitter of transistor Q1 is grounded through resistor R5, the collector of transistor Q1 is connected to the anode of diode D1, the positive pole of capacitor C1 is connected to the cathode of diode D1, and the negative pole is grounded. The first end of resistor R1 is connected to th...

Embodiment 3

[0038] Example 3, such as Figure 5 as shown,

[0039] The urea injection control unit includes a jet pump control circuit, the jet pump control circuit includes driver chips U2 and U3, the input pin IN of the driver chip U2 is connected to the PB_M1 signal output by the central control unit, and the output pin OUT of the driver chip U2 is connected to the jet pump motor The input pin IN of the drive chip U3 is connected to the PB_M2 signal output by the central control unit, and the output pin OUT of the drive chip U3 is connected to the second end of the jet pump motor.

[0040] The injection pump is a power device for injecting urea water in the pipeline. It mainly uses the rotation of the internal DC motor rotor to make the eccentric wheel on the shaft drive the diaphragm to reciprocate, thereby adjusting the injection pressure inside the pipeline. This pressure can be divided into There are two parts, positive pressure and negative pressure. Negative pressure can be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com