Special repairing agent for boiler flue gas desulfurization tower and production process of special repairing agent

A technology of boiler flue gas and production process, applied in coating, grain treatment, special surface and other directions, can solve the problems of steel plate corrosion of desulfurization tower tower wall, easy corrosion of desulfurization tower inner wall, affecting the safe operation of equipment, etc., to improve protection The effect of performance, convenient construction and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

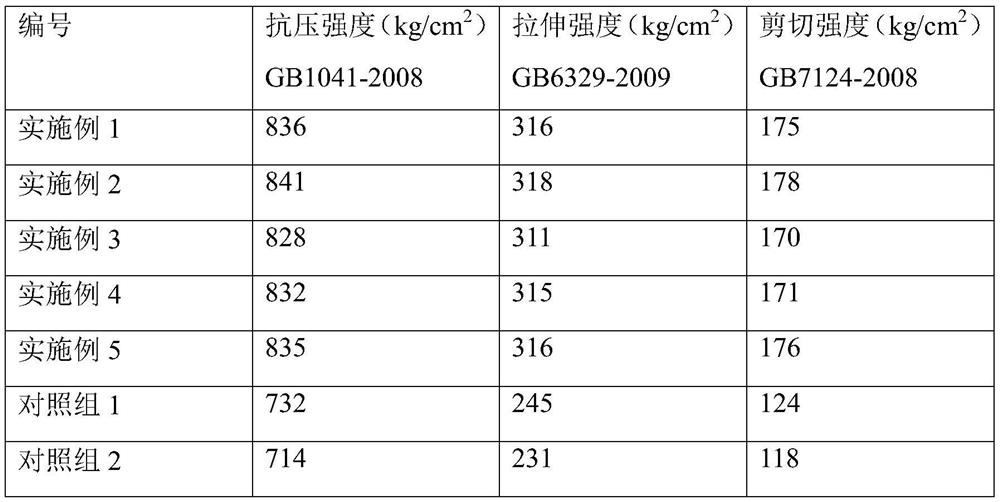

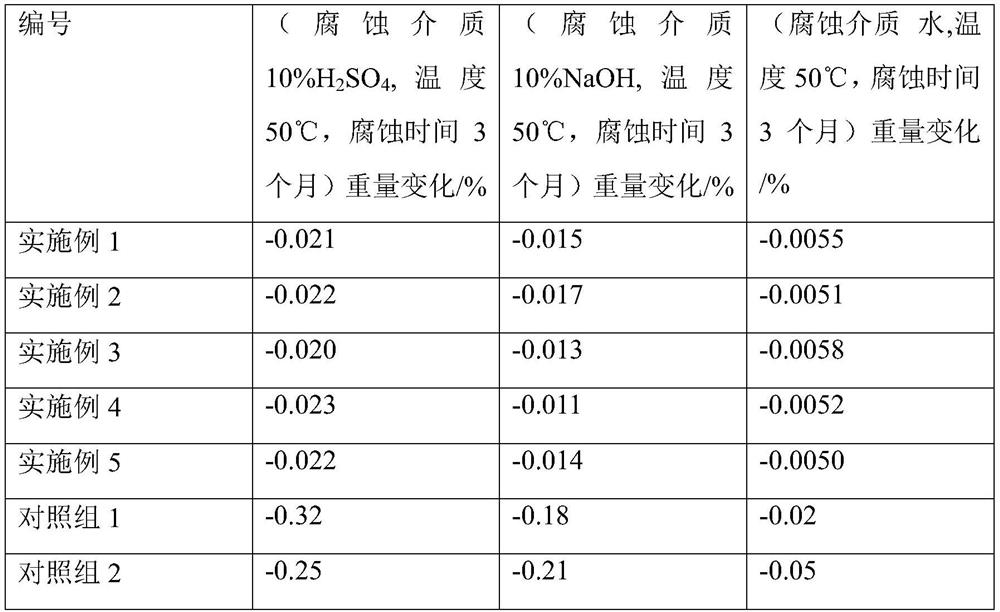

Examples

preparation example Construction

[0029] (1) Preparation of corrosion-resistant layer: take each raw material successively according to the weight ratio, put fly ash, carbon fiber, silicon steel, and ceramic particles into a ball mill for grinding, and the rotating speed of the ball mill is 700-1200r / min. Grind at 30°C for 1 hour to obtain premix A; put polyurethane modified epoxy resin, graphene modified epoxy resin, and acetone into a blender and mix evenly to obtain premix B; under constant stirring, premix B Mixture A is slowly added to premix B in batches, after the addition is complete, stir and mix evenly, add a curing agent, stir and mix evenly again to obtain a corrosion-resistant coating; apply the corrosion-resistant coating to the area to be repaired on the inner wall of the desulfurization tower Spraying, before spraying, perform surface grinding treatment on the area to be repaired. The thickness of spraying is 0.3mm~0.4mm. After spraying, a corrosion-resistant layer is obtained, and the corrosion...

Embodiment 1

[0035] A special repair agent for boiler flue gas desulfurization tower, the repair agent is a multi-layer composite coating, including a wear-resistant layer, a bonding layer, a corrosion-resistant layer, and a corrosion-resistant layer that are sequentially coated on the inner wall of the desulfurization tower from top to bottom Closely attached to the inner wall of the desulfurization tower, the total thickness of the repair agent is 1.8mm, wherein the thickness of the wear-resistant layer is 0.5mm, the thickness of the bonding layer is 1mm, and the thickness of the corrosion-resistant layer is 0.3mm.

[0036] The wear-resistant layer is prepared from the following raw materials in parts by weight: 20 parts of vinyl glass flake glue, 5 parts of alumina corundum ceramic balls, 5 parts of modified hollow glass microspheres, 5 parts of silicon carbide, 5 parts of zirconia, titanium 5 parts of tungsten alloy powder, 30 parts of styrene.

[0037] The binding layer is prepared fr...

Embodiment 2

[0044] A special repair agent for boiler flue gas desulfurization tower, the repair agent is a multi-layer composite coating, including a wear-resistant layer, a bonding layer, a corrosion-resistant layer, and a corrosion-resistant layer that are sequentially coated on the inner wall of the desulfurization tower from top to bottom Closely attached to the inner wall of the desulfurization tower, the total thickness of the repair agent is 2.5mm, of which the thickness of the wear-resistant layer is 0.6mm, the thickness of the bonding layer is 1.5mm, and the thickness of the corrosion-resistant layer is 0.4mm.

[0045] The wear-resistant layer is prepared from the following raw materials in parts by weight: 40 parts of vinyl glass flake glue, 10 parts of alumina corundum ceramic balls, 10 parts of modified hollow glass microspheres, 10 parts of silicon carbide, 10 parts of zirconia, titanium 10 parts of tungsten alloy powder, 40 parts of styrene.

[0046] The bonding layer is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com