Generation system of standard gaseous nitric acid peroxide and preparation method thereof

A peroxynitric acid generation system technology, applied in standard gas analyzers, chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc., to achieve easy-to-operate structure, Gas distribution and calibration operations are simple and easy, and the effect of fewer reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

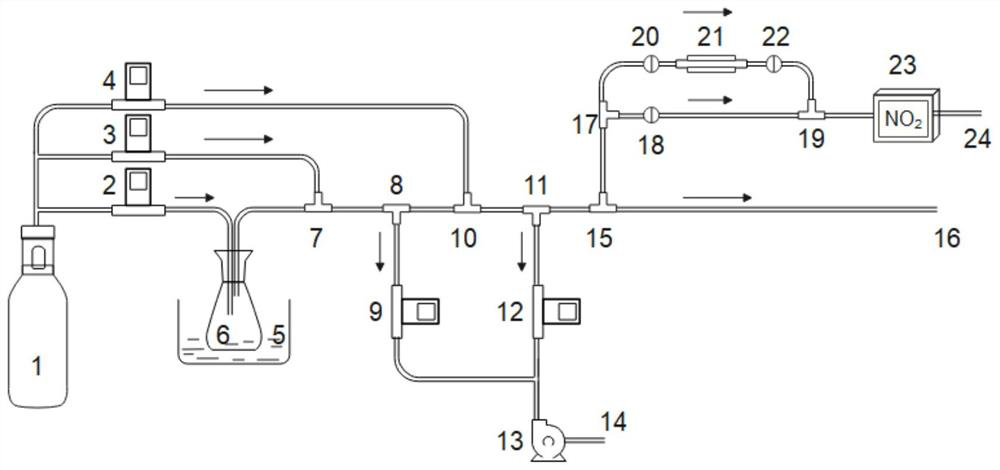

[0041] Embodiment 1: a kind of generation system of standard gaseous peroxynitric acid

[0042] like figure 1 As shown, the generation system of the standard gaseous peroxynitric acid includes a gas supply structure, a peroxynitric acid solution storage structure, a gaseous peroxynitric acid dilution structure, an exhaust structure, a gaseous peroxynitric acid calibration structure, and a calibration instrument connection structure.

[0043] The gas supply structure includes a high-pressure nitrogen source 1 .

[0044] The peroxynitric acid solution storage structure includes a cooling unit 5 and a glass container 6 arranged on the top of the cooling unit 5 . The gas outlet of the high-pressure nitrogen source 1 communicates with the gas inlet of the glass container 6 through the first mass flow controller 2 .

[0045] The gaseous peroxynitric acid dilution structure includes a first three-way joint 7 and a third three-way joint 10 . The air outlet of the glass container 6 ...

Embodiment 2

[0049] Embodiment 2: a kind of preparation method of standard gaseous peroxynitric acid

[0050] Adopt the generation system of the standard gaseous peroxynitric acid of embodiment 1 to prepare the standard gaseous peroxynitric acid that calibration instrument is used, concrete steps are as follows:

[0051] (1) prepare peroxynitric acid solution

[0052] In a dry and anhydrous atmosphere (operate in a glove box, pass in nitrogen to completely discharge the air in the box), take 1 mL of 50% hydrogen peroxide solution and pre-cool it below 0°C; use an ice-salt bath at a temperature of Pre-cool the hydrogen peroxide solution at -10°C.

[0053] Take 0.1g tetrafluoroborate nitric acid (NO 2 BF 4 ) Solid is added in the described precooling hydrogen peroxide solution, makes peroxynitric acid solution. The peroxynitric acid solution is transferred to the glass container 6, and the low temperature state of the peroxynitric acid solution in the glass container 6 is maintained by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com