Preparation method of ultrathin chalcogenide glass

A technology of chalcogenide glass and ultra-thin glass, applied in glass manufacturing equipment, glass forming, glass re-molding and other directions, can solve the problems of unsuitable production of chalcogenide glass, affecting the surface quality of ultra-thin glass, etc., and achieve good flexibility and controllable, strong densification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

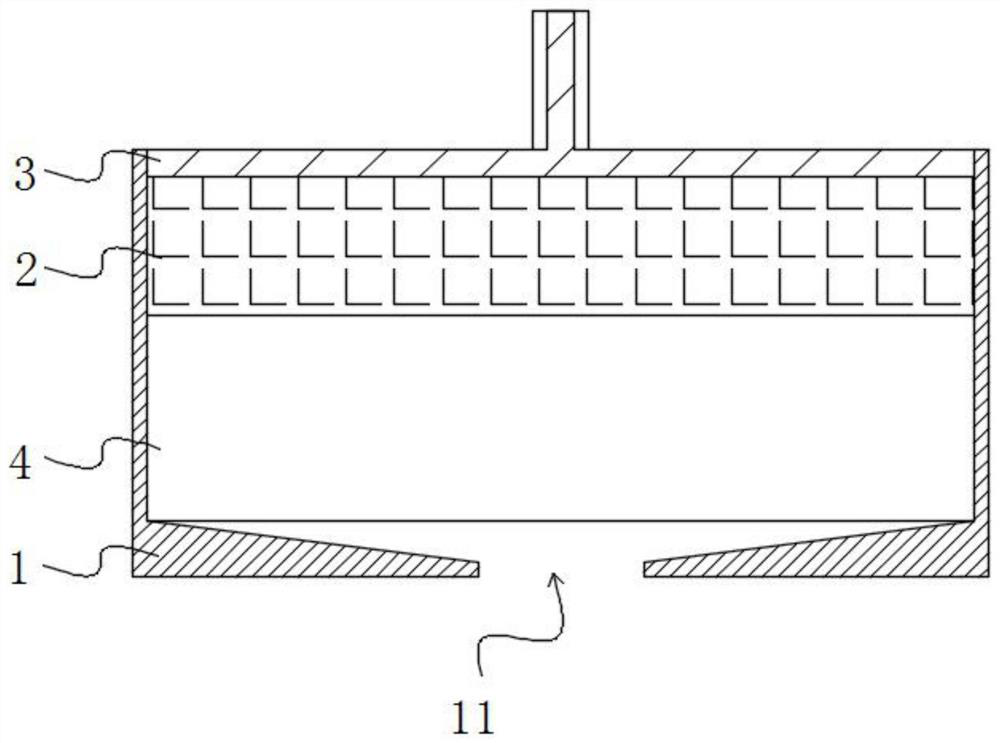

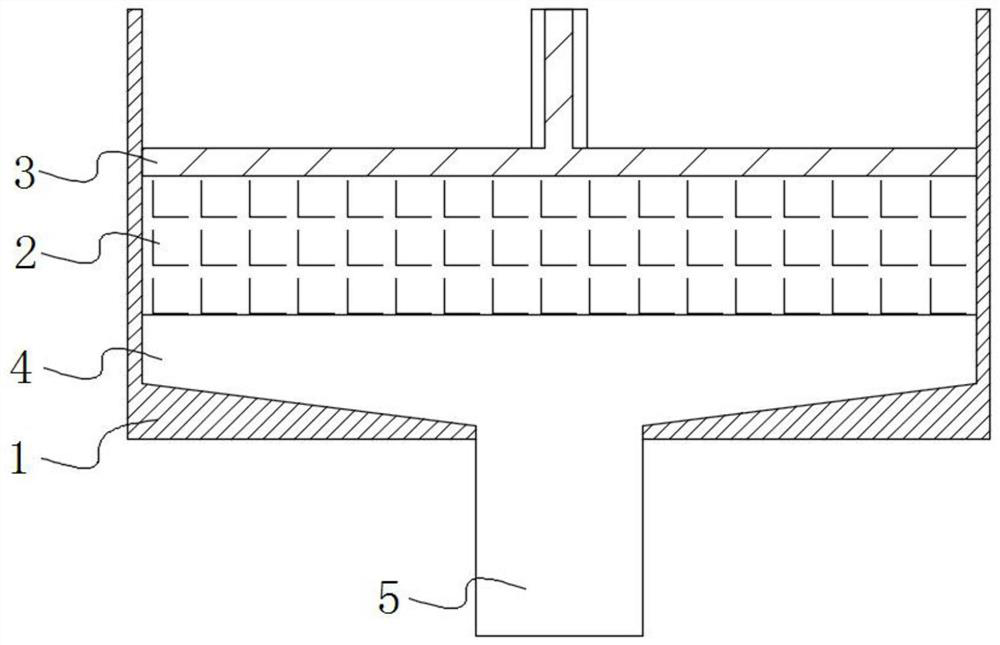

[0051] In this embodiment, what is to be prepared is a single-layer chalcogenide ultra-thin glass, and the selected chalcogenide glass ingot 4 is Ge 10 As 22 Se 68 ; see Figure 1 to Figure 4 shown. First prepare the prefabricated ultra-thin chalcogenide glass 5, which is made by the following steps:

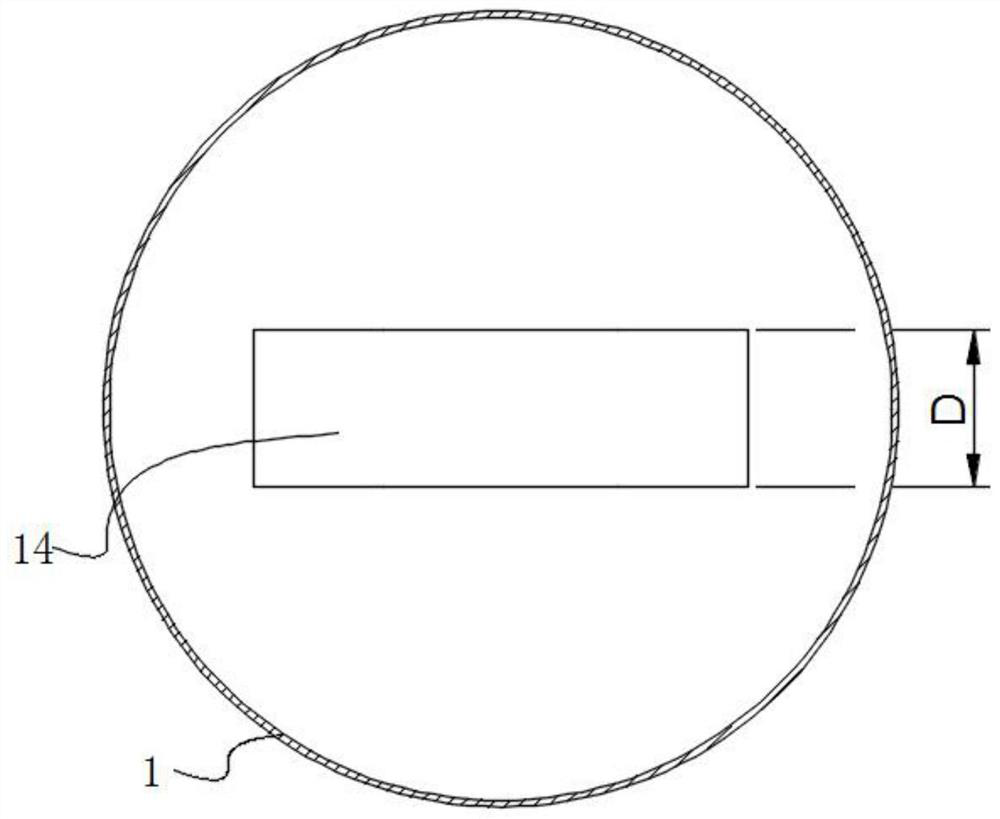

[0052] Step S1, pre-preparing the extrusion cylinder 1, the extrusion sheet 2 and the pressure rod 3, the extrusion cylinder 1 has a top opening and the bottom of the extrusion cylinder 1 is provided with a rectangular extrusion port 11; the outer surface of the extrusion sheet 2 diameter and the outer diameter of the pressure rod 3 are smaller than the size of the upper opening of the extrusion cylinder 1;

[0053] Step S2, preparing the cleaned and dried chalcogenide glass ingot 4, the outer diameter of the chalcogenide glass ingot 4 is equal to the outer diameter of the extruded sheet 2;

[0054] Step S3, putting the chalcogenide glass ingot 4 into the bottom of the extr...

Embodiment 2

[0096] like Figure 9 As shown, what is to be prepared in this embodiment is double-layer ultra-thin chalcogenide glass, which requires two kinds of chalcogenide glass ingots 4 with different refractive indices. Specifically, the glass ingots are Ge glass with high refractive index. 9 As 23 Se 68 and low-index Ge 10 As 22 Se 68 .

[0097] First of all, it is necessary to prepare prefabricated ultra-thin chalcogenide glass 5, according to steps S1-S6 in Example 1 to finally obtain Ge with a high refractive index 9 As 23 Se 68 Prefabricated ultrathin chalcogenide glass 5 and low-index Ge 10 As 23 Se 68 Prefabricated ultra-thin chalcogenide glass5.

[0098] Specifically, the chalcogenide glass ingot 4 in steps S1-S6 is composed of two materials in equal proportions, which are high refractive index Ge 9 As 23 Se 68 Glass ingot and low refractive index Ge 10 As 23 Se 68 For the glass ingot, the bonding surface of the two materials is a vertical surface, and the ver...

Embodiment 3

[0102] like Figure 10 As shown, the three-layer ultra-thin chalcogenide glass to be prepared in this embodiment requires three kinds of chalcogenide glass ingots 4 with different refractive indices, specifically, Ge 8 As 24 Se 68 , higher refractive index Ge 9 As 23 Se 68 and low-index Ge 10 As 23 Se 68 , the three ultra-thin chalcogenide glasses are referred to as the first ultra-thin chalcogenide glass 8 , the second ultra-thin chalcogenide glass 9 and the third ultra-thin chalcogenide glass 10 .

[0103] First of all, it is necessary to prepare prefabricated ultra-thin chalcogenide glass 5 respectively, and according to steps S1-S6 in Example 1, Ge glass with high refractive index is finally prepared. 8 As 24 Se 68 , higher refractive index Ge 9 As 23 Se 68 and low-index Ge 10 As 23 Se 68 Composition of prefabricated ultra-thin chalcogenide glass 5.

[0104] Specifically, such as Figure 10 As shown, the chalcogenide glass ingot 4 in steps S1-S6 is compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com