Bio-based antibacterial ultraviolet fluorescent coating and preparation method thereof

A fluorescent coating, bio-based technology, applied in luminescent coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as harm to human health, and achieve the effects of low cost, simple preparation method, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of bio-based antibacterial ultraviolet fluorescent coating, the preparation method is carried out according to the following steps:

[0041] S1. Dissolve 5',5-diallyl-2,2'-diphenol and 1,6-hexanedithiol in an organic solvent at room temperature at a stirring speed of 200-400r / min to obtain mixture.

[0042] Among them, the mass fraction ratio of 5',5-diallyl-2,2'-diphenol and 1,6-hexanedithiol is 65-80: 20-35, the mass fraction of solute and solvent The ratio is 10-20:80-90.

[0043]The organic solvent is one of toluene or acetone or DMSO or DMF.

[0044] S2. Add catalyst b to the mixed solution obtained in step S1, the mass fraction ratio of catalyst b to solute in S1 is 1-5:100; and raise the temperature to 60-100°C, stirring at 600-800r / min The reaction speed is 4-6h.

[0045] S3. Add the product solution obtained after the reaction in step S2 into the cyclohexane solution, stir at a speed of 500~1000r / min for 20min, and then let it stand, ...

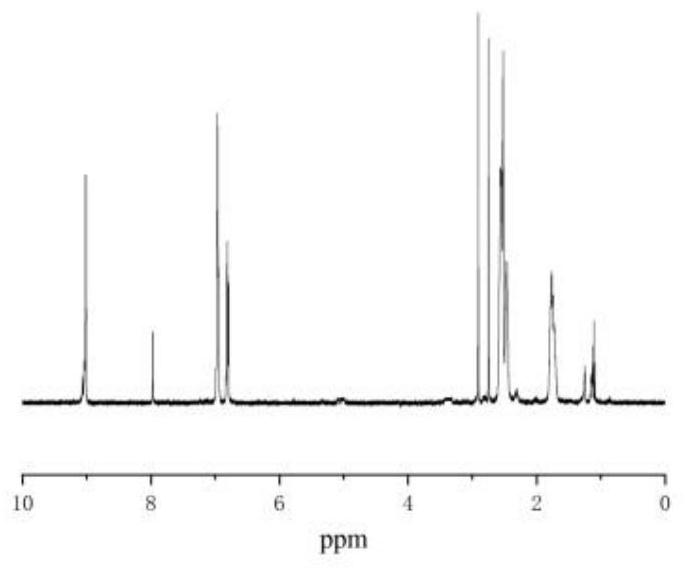

Embodiment 1

[0055] Preparation method of bio-based antibacterial ultraviolet fluorescent coating.

[0056] According to the above preparation method:

[0057] S1. Dissolve 6.5g of 5',5-diallyl-2,2'-diphenol and 3.5g of 1,6-hexanedithiol in 90g of toluene at room temperature with a stirring speed of 200r / min , to obtain a mixed solution.

[0058] S2. Add 100mg of azobisisobutyronitrile into the mixed solvent obtained in step S1, and raise the temperature to 60°C, and react at a stirring speed of 600r / min for 6h.

[0059] S3. The product solution obtained in step S2 was added to 900 g of cyclohexane solution, stirred at a speed of 500 r / min for 20 min, and then left to stand.

[0060] S4. Remove the supernatant of the solution obtained in step S3, collect the colloidal precipitate in the lower layer, and dry at 30°C and 0.09Mpa for 30min to obtain a prepolymer.

[0061] S5. Stir the prepolymer obtained in step S4 and 1.1 g of trimethylolpropane tris(3-mercaptopropionate) at 80° C. to mix...

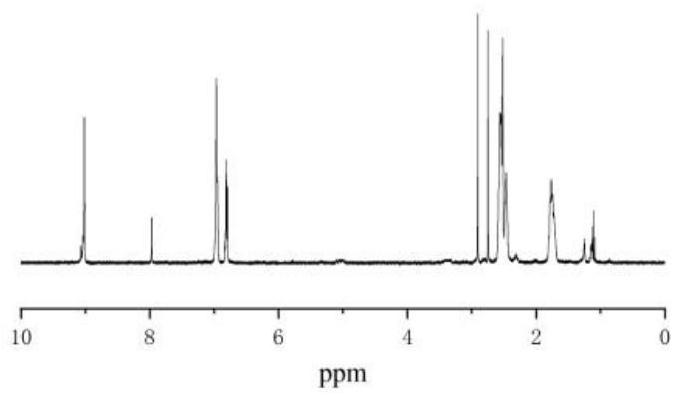

Embodiment 2

[0069] Preparation method of bio-based antibacterial ultraviolet fluorescent coating.

[0070] According to the above preparation method:

[0071] S1. Dissolve 8.0g of 5',5-diallyl-2,2'-diphenol and 2.0g of 1,6-hexanedithiol in 100g of toluene at room temperature with a stirring speed of 200r / min , to obtain a mixed solution.

[0072] S2. Add 500mg of azobisisobutyronitrile into the mixed solvent obtained in step S1, and raise the temperature to 100°C, and react at a stirring speed of 600r / min for 4h.

[0073] S3. The product solution obtained in step S2 was added to 1900 g of cyclohexane solution, stirred at a speed of 500 r / min for 20 min, and then left to stand.

[0074] S4. Remove the supernatant of the solution obtained in step S3, collect the colloidal precipitate in the lower layer, and dry at 30°C and 0.09Mpa for 30min to obtain a prepolymer.

[0075] S5. Stir the prepolymer obtained in step S4 and 2.5 g of trimethylolpropane tris(3-mercaptopropionate) under the con...

PUM

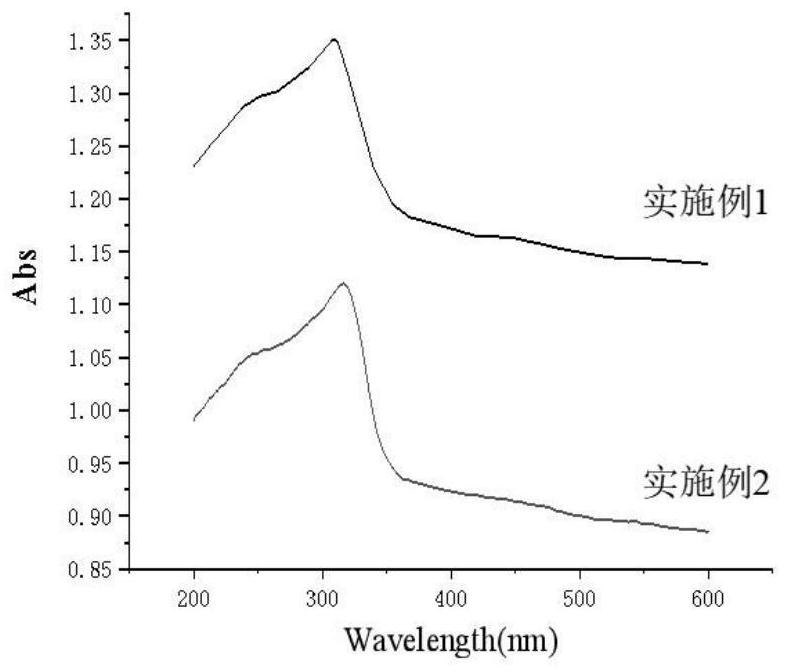

| Property | Measurement | Unit |

|---|---|---|

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com