Chemical tail gas treatment device with recovery function

A chemical exhaust gas treatment and function technology, applied in valve operation/release device, valve device, pump device, etc., can solve the problems of heat energy loss, waste, and the circuit switching is not uniform and smooth, and achieves the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

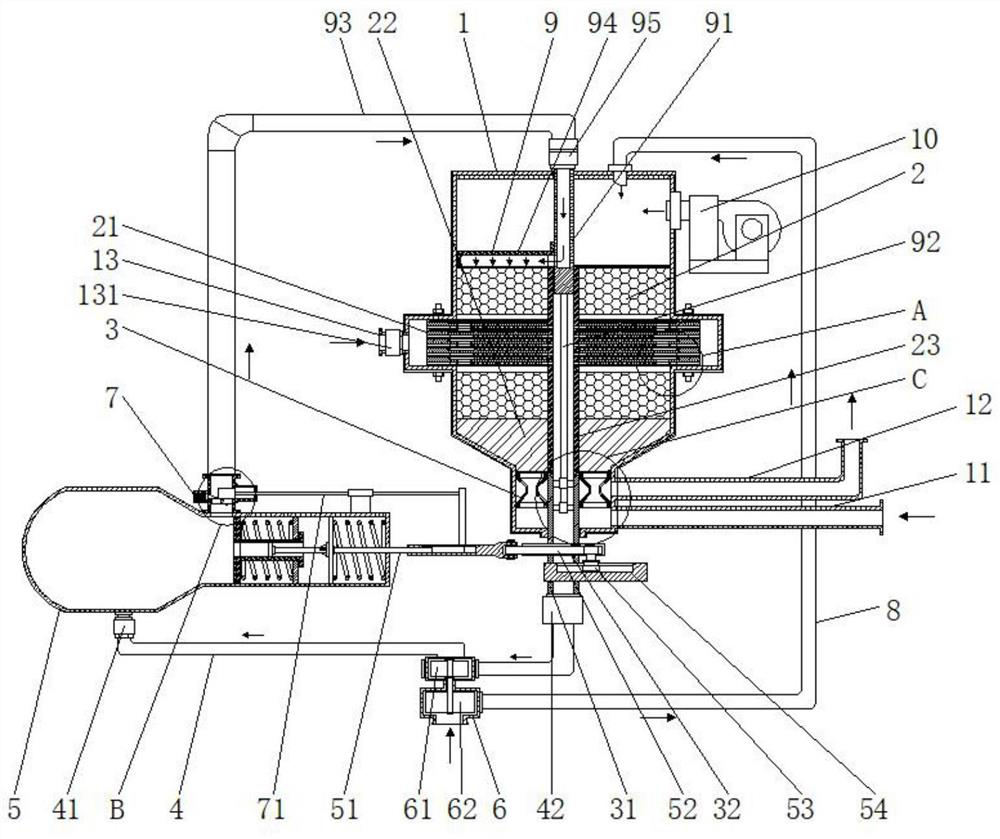

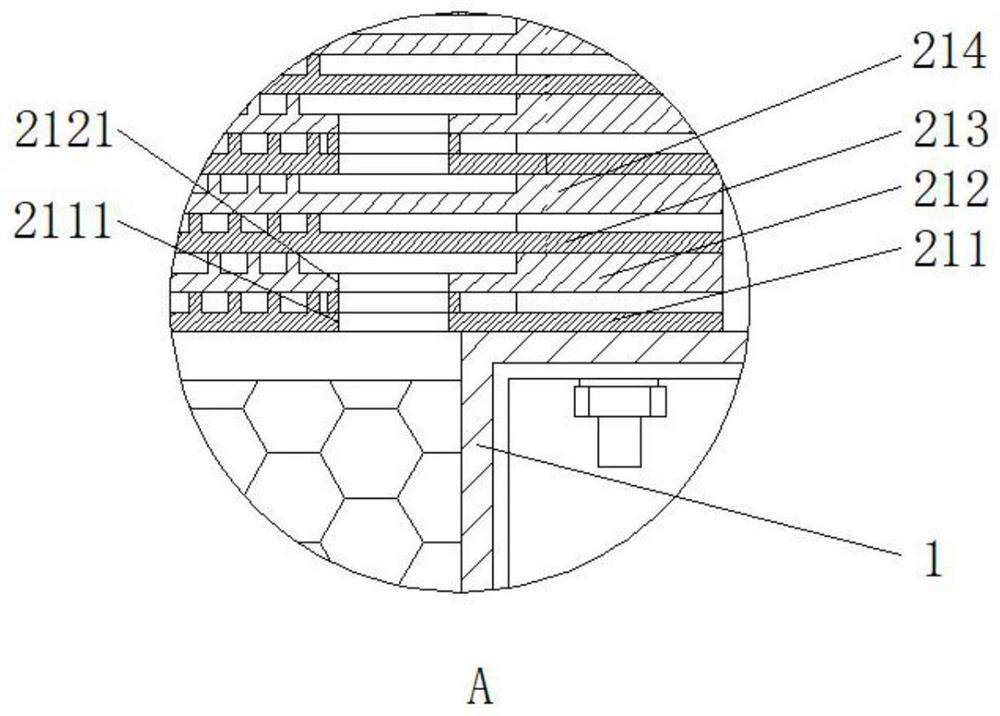

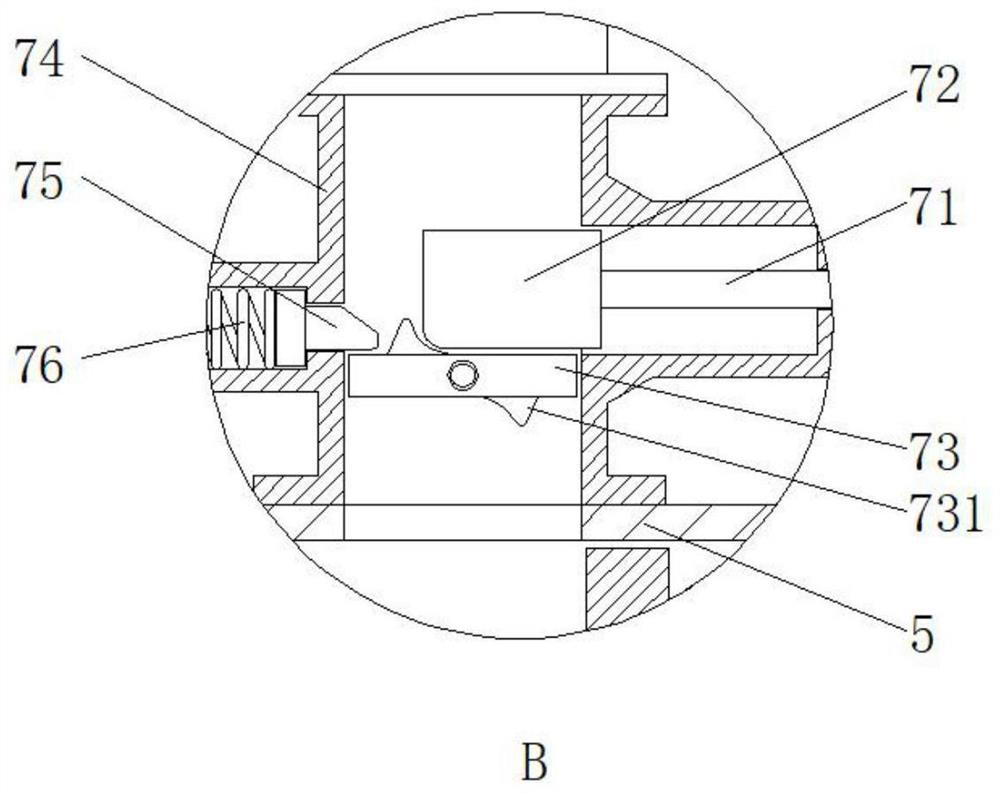

[0050] The present invention provides a kind of chemical tail gas treatment device with recovery function through improvement, such as Figure 1-Figure 16 As shown, a chemical tail gas treatment device with recovery function includes an incineration tank body 1, a burner 10 is connected to the top of one side of the incineration tank body 1, and a heat exchange combined heat storage body 2 is arranged inside the incineration tank body 1. The lower end of the heat exchange combined regenerator 2 is connected to one end of the steam transmission pipe 4 through the rotary valve assembly 3, the middle part of the steam transmission pipe 4 is connected to the oxygen booster pipe 8 through the turbocharger machine 6, and the steam transmission pipe 4 The other end is connected with a steam-powered push-pull tank 5, and one side of the steam-powered push-pull tank 5 is connected with an air jet cleaning assembly 9 through a passive pulse valve 7, and the air jet cleaning assembly 9 is...

Embodiment 2

[0061] The present invention provides a kind of chemical tail gas treatment device with recovery function through improvement, such as Figure 1-Figure 16 As shown, a chemical tail gas treatment device with recovery function includes an incineration tank body 1, a burner 10 is connected to the top of one side of the incineration tank body 1, and a heat exchange combined heat storage body 2 is arranged inside the incineration tank body 1. The lower end of the heat exchange combined regenerator 2 is connected to one end of the steam transmission pipe 4 through the rotary valve assembly 3, the middle part of the steam transmission pipe 4 is connected to the oxygen booster pipe 8 through the turbocharger machine 6, and the steam transmission pipe 4 The other end is connected with a steam-powered push-pull tank 5, and one side of the steam-powered push-pull tank 5 is connected with an air jet cleaning assembly 9 through a passive pulse valve 7, and the air jet cleaning assembly 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com