Insect-shaped carbon material for supercapacitor and application of insect-shaped carbon material

A technology of supercapacitors and carbon materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, and can solve the problems of reducing surface area normalized capacitance, increasing cost, and incomplete charge shielding capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

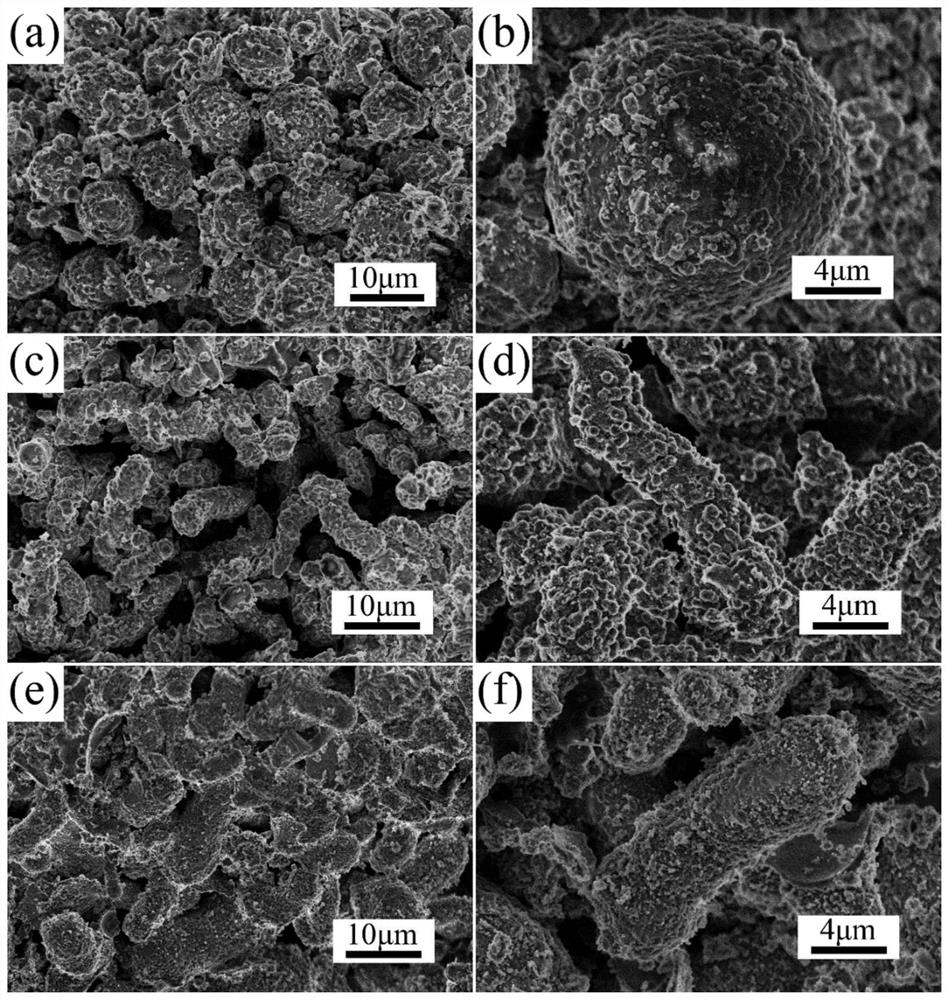

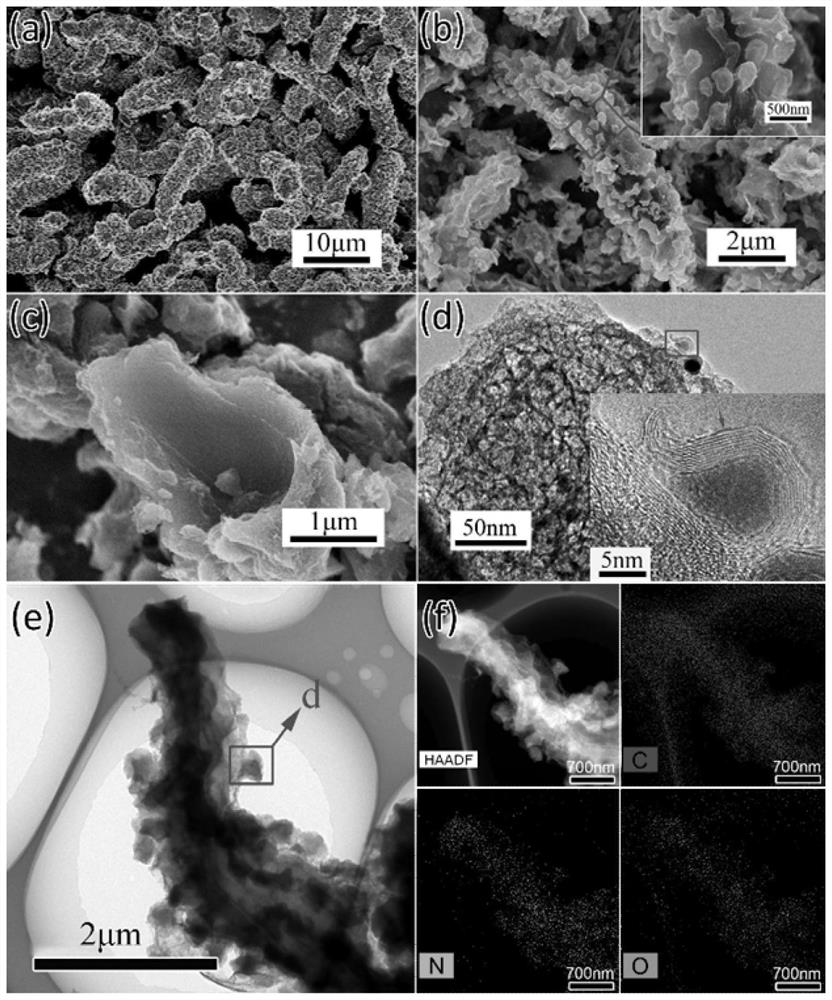

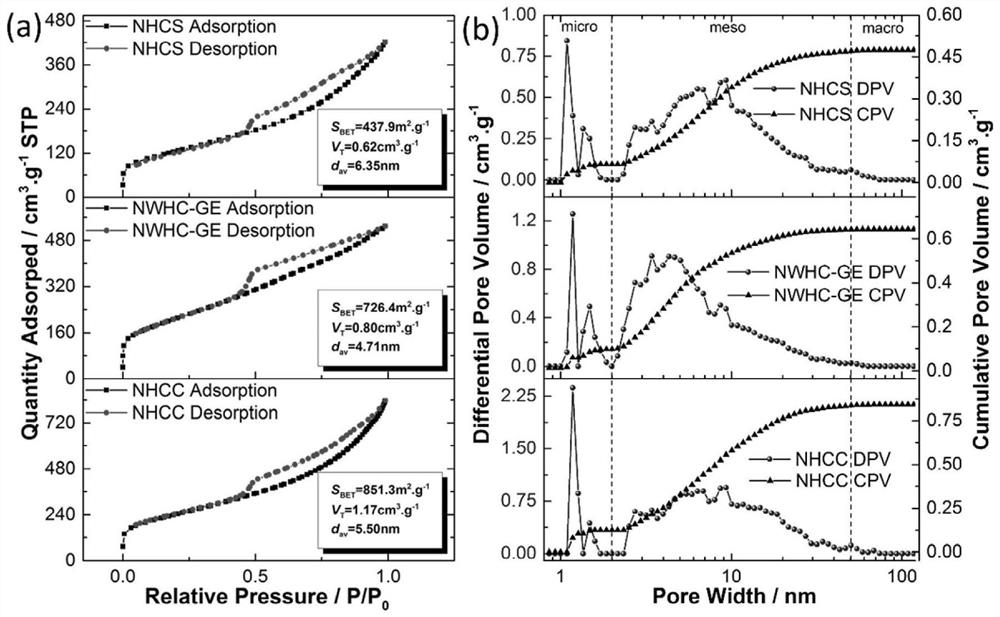

[0036] The invention provides a kind of worm-like carbon material that supercapacitor is used, and its preparation method comprises the following steps:

[0037] (1) heating the mixture of melamine, formaldehyde and water to convert insoluble melamine molecules into its soluble methylol derivatives to obtain a prepolymer solution of melamine-formaldehyde resin polymer, which is solution A;

[0038] (2) Prepare a mixed solution containing emulsifier, silicon source and ferrous sulfate to obtain emulsion B;

[0039] (3) Add solution A to emulsion B under stirring, and stir the mixed system to obtain MF / silica / Fe 2+ Complex. The prepolymers of MF were cross-linked and aggregated around the surface of surfactant micelles to form MF capsules, while the silicon source was hydrolyzed into silica and incorporated into the clusters, resulting in a change in the surface morphology of the MF capsules. Ferrous sulfate is the key influencing factor for the formation of worm-like structur...

Embodiment 1

[0046] Add 9.45 g (75 mmol) of melamine and 15.0 mL (196 mmol) of formaldehyde solution (36 wt%) into 37.5 mL of deionized water and stir at 85 °C for 30 min to obtain a clear solution (referred to as solution A). Tetraethyl orthosilicate (15 mL, purity ≥99.9%), OP-10 (7.5 mL, 10 wt % aqueous solution) and 0.01 mol ferrous sulfate were mixed and stirred in deionized water for 60 ℃ in a water bath at 50 °C with magnetic stirring. minutes to obtain an olive green emulsion (named Emulsion B). The A solution was slowly added to B after cooling, after that, the pH of the mixture was adjusted to 4.5 by using HCl solution (2.0 M), and the mixture was continuously stirred for 2 h to obtain MF / SiO / Fe 2+ Complex. These composites were collected by filtration, washed repeatedly with water and ethanol three times, and dried in air at 80 °C. To prepare sample one, firstly the MF / SiO2 / Fe 2+ The composites were cured in air at 200 °C for 24 h, and then carbonized at 900 °C for 2 h in an a...

Embodiment 2

[0048] Add 9.45 g (75 mmol) of melamine and 15.0 mL (196 mmol) of formaldehyde solution (36 wt%) into 37.5 mL of deionized water and stir at 85 °C for 30 min to obtain a clear solution (referred to as solution A). Tetraethyl orthosilicate (15 mL, purity ≥99.9%), OP-10 (7.5 mL, 10 wt % aqueous solution) and 0.02 mol ferrous sulfate were mixed and stirred in deionized water for 60 ℃ in a water bath at 50 °C with magnetic stirring. minutes to obtain an olive green emulsion (named Emulsion B). The A solution was slowly added to B after cooling, after that, the pH of the mixture was adjusted to 4.5 by using HCl solution (2.0 M), and the mixture was continuously stirred for 2 h to obtain MF / SiO / Fe 2+ Complex. These composites were collected by filtration, washed repeatedly with water and ethanol three times, and dried in air at 80 °C. To prepare sample one, firstly the MF / SiO2 / Fe 2+ The composites were cured in air at 200 °C for 24 h, and then carbonized at 900 °C for 2 h in an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com