Aluminum oxide for coating ceramic diaphragm of lithium battery and preparation method of aluminum oxide

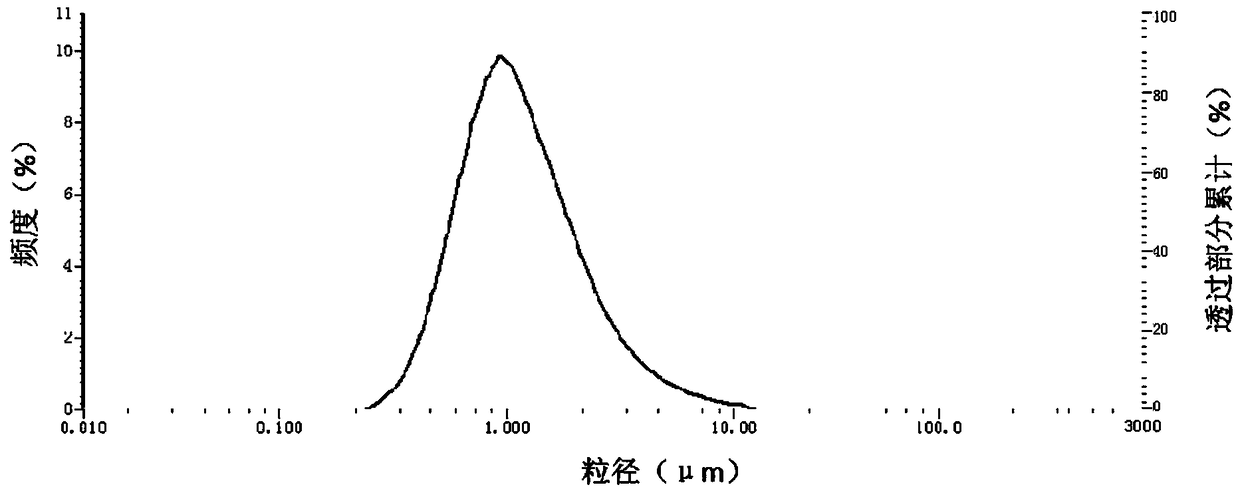

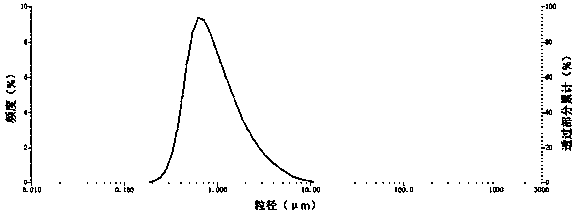

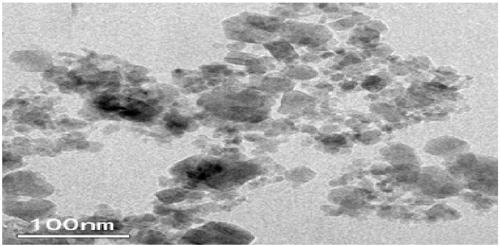

A ceramic diaphragm, alumina technology, applied in alumina/hydroxide preparation, chemical instruments and methods, alumina/aluminum hydroxide and other directions, can solve the problems of high cost, agglomeration, wide powder particle size distribution, etc. Effects of low content of magnetic substances, low content of magnetic substances, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Preparation of ammonium aluminum carbonate precursor:

[0061] The preparation of aluminum ammonium sulfate aqueous solution: 4kg aluminum ammonium sulfate is added into 96kg pure water, obtains clear and transparent 100kg aluminum ammonium sulfate aqueous solution, wherein, by mass fraction, the content of aluminum ammonium sulfate is 4%;

[0062] The preparation of ammonium bicarbonate aqueous solution: join 4.44kg ammonium bicarbonate, 1.48kg polyvinyl alcohol into 43.4kg pure water, stir, obtain clear and transparent 49.32kg ammonium bicarbonate aqueous solution, wherein, by mass fraction, ammonium bicarbonate The content of the dispersant is 9%; the content of the dispersant is 3%;

[0063] Under stirring conditions, add ammonium aluminum sulfate dropwise to the ammonium bicarbonate aqueous solution, and control the temperature of the solution at 10-50°C. After the dropwise addition, continue to stir and homogenize for 1 hour, then age for 12 hours, and finally...

Embodiment 2

[0071] (1) Preparation of ammonium aluminum carbonate precursor:

[0072] The preparation of aluminum ammonium sulfate aqueous solution: 10kg aluminum ammonium sulfate is added into 90kg pure water, obtains clear and transparent 100kg aluminum ammonium sulfate aqueous solution, wherein, by mass fraction, the content of aluminum ammonium sulfate is 4%;

[0073] The preparation of ammonium bicarbonate aqueous solution: join 11.1kg ammonium bicarbonate, 5.18kg polypropylene alcohol, into 57.72kg pure water, stir, obtain clear and transparent 74kg ammonium bicarbonate aqueous solution, wherein, by mass fraction, ammonium bicarbonate The content of the dispersant is 15%; the content of the dispersant is 7%;

[0074] Under stirring conditions, add ammonium aluminum sulfate dropwise to the aqueous ammonium bicarbonate solution, and control the temperature of the solution to 50°C. After the dropwise addition, continue to stir and homogenize for 1 hour, then age for 12 hours, and final...

Embodiment 3

[0082] (1) Preparation of ammonium aluminum carbonate precursor:

[0083] The preparation of aluminum ammonium sulfate aqueous solution: 6kg aluminum ammonium sulfate is added into 94kg pure water, obtains clear and transparent 100kg aluminum ammonium sulfate aqueous solution, wherein, by mass fraction, the content of aluminum ammonium sulfate is 4%;

[0084] Preparation of ammonium bicarbonate aqueous solution: add 6.66kg of ammonium bicarbonate, 1.11kg of hexadecylbenzenesulfonic acid, 1.11kg of Span 40, and 1.11kg of polyethylene glycol into 56.61kg of pure water and stir to obtain a clear and transparent 66.6kg ammonium bicarbonate aqueous solution, wherein, by mass fraction, the content of ammonium bicarbonate is 10%; The content of dispersant is 5%;

[0085] Under stirring conditions, add ammonium aluminum sulfate dropwise to the aqueous ammonium bicarbonate solution, and control the temperature of the solution to 30°C. After the dropwise addition, continue to stir and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com