Method for preparing uniform lithium ion battery ternary cathode material by one-step in-situ complexation

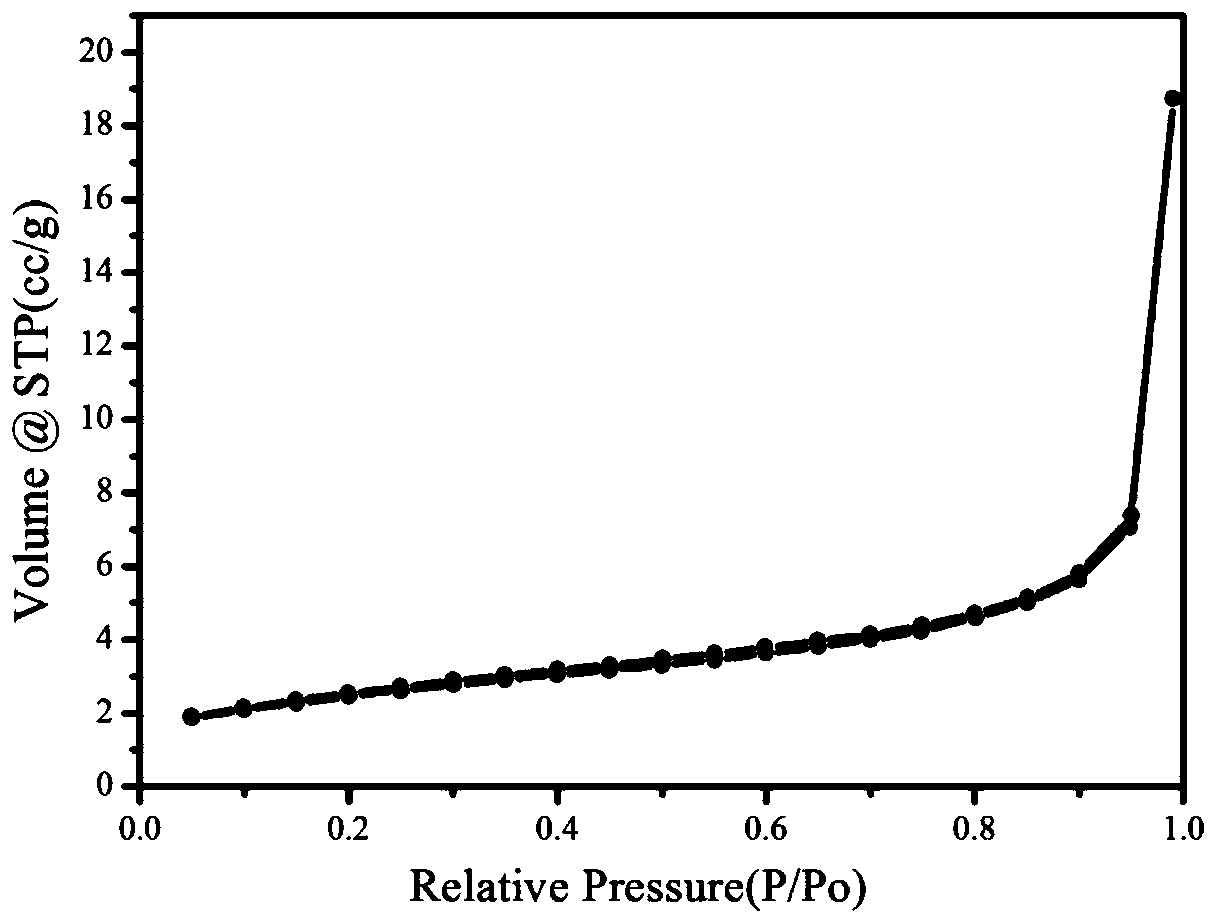

A technology for lithium-ion batteries and cathode materials, which is applied in the field of one-step in-situ complexation to prepare uniform lithium-ion battery ternary cathode materials, can solve the problems of metal alkoxide toxicity, high cost, and complicated process, and achieve good electrochemical performance. Appropriate performance and specific surface area, suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

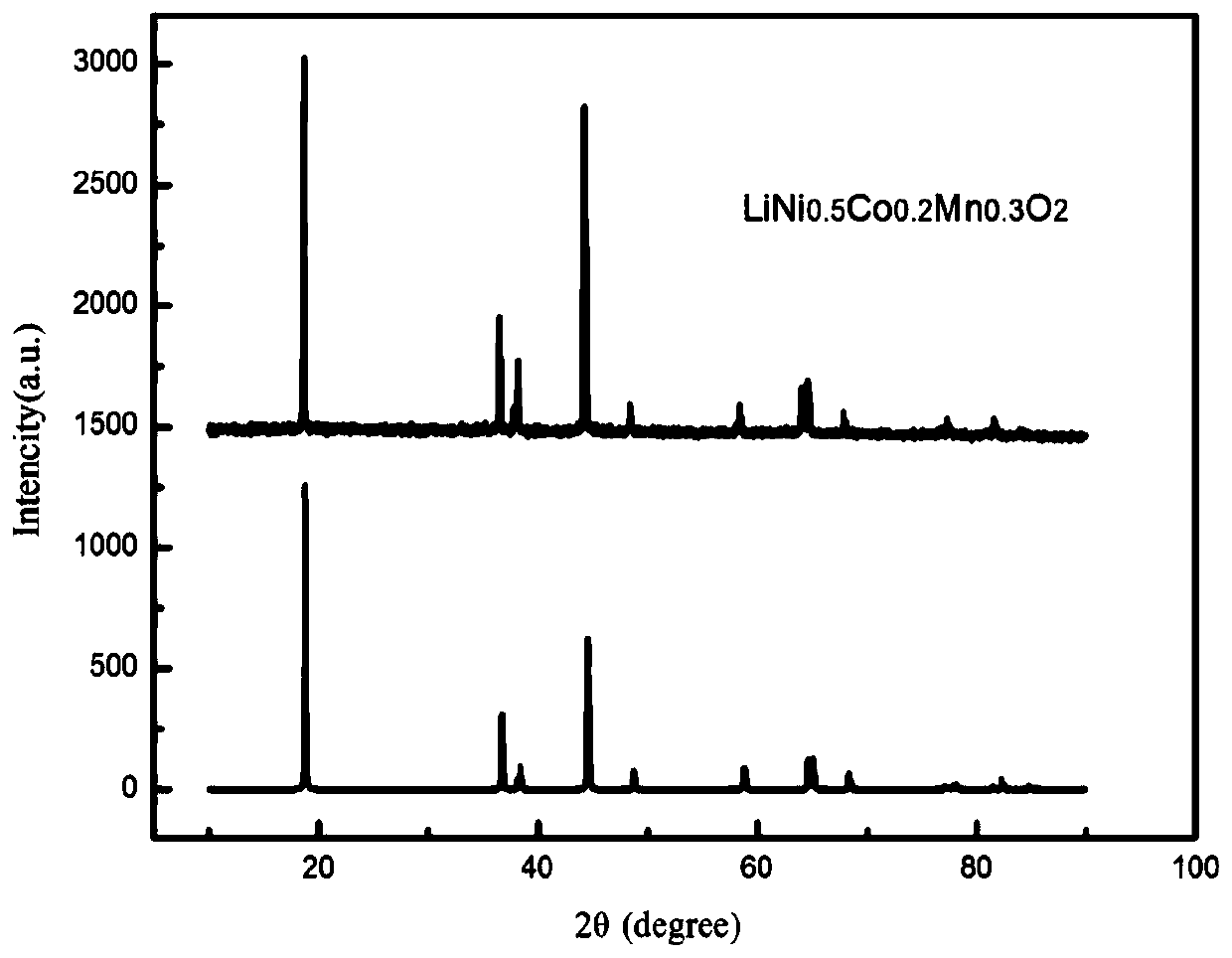

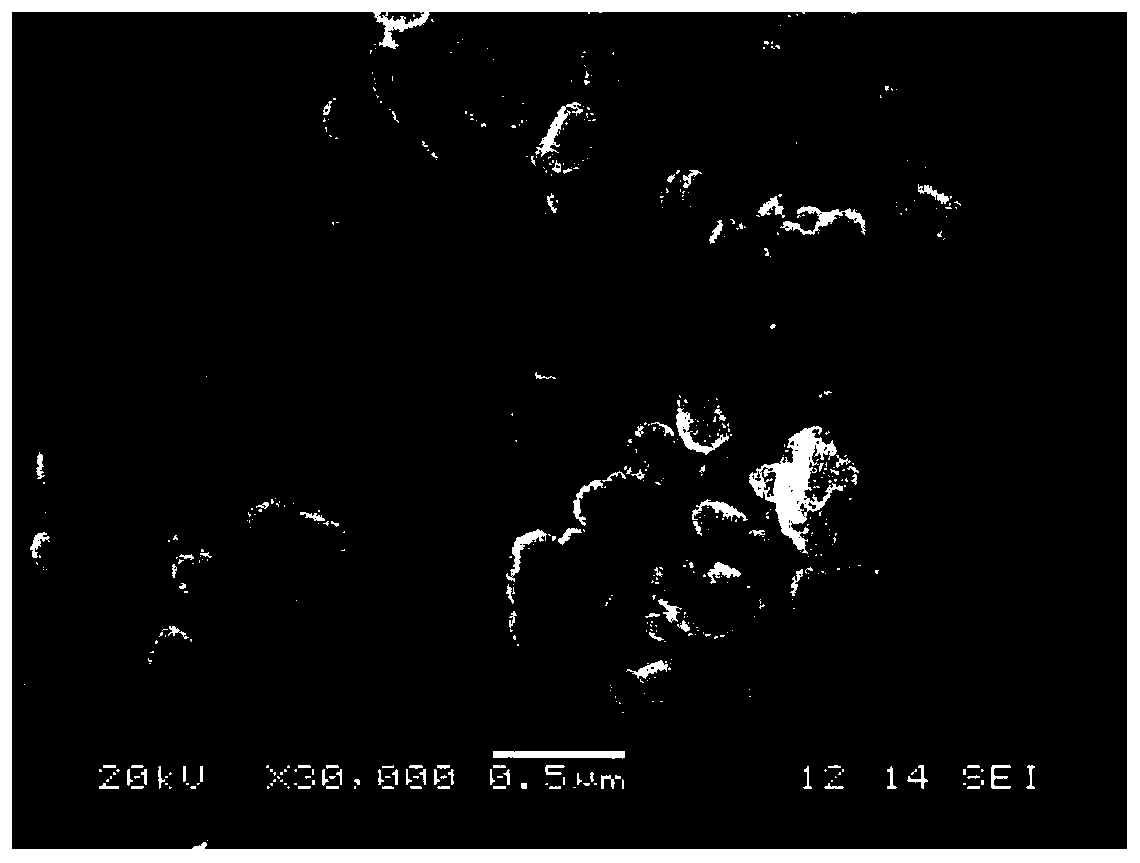

[0034] A kind of lithium-ion battery ternary cathode material (LiNi 0.5 mn 0.2 co 0.3 o 2 ), its synthesis process comprises the following steps:

[0035] 1) Weigh 1g of glucose and 1g of urea respectively, place them in a small beaker, stir at 120°C for 20min, and wait for complete dissolution to form a homogeneous sol;

[0036] 2) Weigh lithium carbonate 0.2108g, nickel nitrate 0.8288g, cobalt nitrate 0.3317g, manganese nitrate 0.4290g (the molar ratio of lithium salt, nickel salt, cobalt salt, manganese salt is 1:0.5:0.2:0.3), add In the obtained homogeneous sol, stir at 120°C for about 2 hours to mix various metal salts evenly to form a black gel;

[0037] 3) Heat-treat the obtained black jelly in a drying oven at 180°C for 12 hours to obtain a black fluffy foamy solid;

[0038] 4) Grind the obtained foamy solid, pretreat it at 500°C for 5h in an air atmosphere, heat it up to 900°C for 10h, and grind it after cooling to room temperature to obtain LiNi 0.5 mn 0.2 co ...

Embodiment 2

[0044] A kind of lithium-ion battery ternary cathode material (LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 ), its synthesis process comprises the following steps:

[0045] 1) Weigh 1g of sucrose and 10g of urea respectively, place them in a small beaker, stir at 120°C for 20min, and wait for complete dissolution to form a homogeneous sol;

[0046] 2) take lithium carbonate 0.2108g, nickel nitrate 0.5528g, cobalt nitrate 0.3317g, manganese nitrate 0.3686g respectively (the mol ratio of lithium salt, nickel salt, cobalt salt, manganese salt is 1:1 / 3:1 / 3: 1 / 3), adding to the obtained homogeneous sol, and stirring at 120°C for about 2 hours to mix various metal salts evenly to form a black jelly;

[0047] 3) The obtained black jelly was placed in a microwave oven with a power of 900W for 5 minutes to obtain a black fluffy foamy solid;

[0048] 4) Grind the obtained foamy solid, pretreat it at 500°C for 5h in an air atmosphere, heat it up to 900°C for 10h, and grind it after cooling to room te...

Embodiment 3

[0051] A kind of lithium-ion battery ternary cathode material (LiNi 0.8 mn 0.1 co 0.1 o 2 ), its synthesis process comprises the following steps:

[0052] 1) Weigh 10g of glucose and 1g of urea respectively, place them in a small beaker, stir at 120°C for 20min, and wait for complete dissolution to form a homogeneous sol;

[0053] 2) Weigh lithium carbonate 0.2108g, nickel nitrate 1.3261g, cobalt nitrate 0.1659g, manganese nitrate 0.1430g (the molar ratio of lithium salt, nickel salt, cobalt salt, manganese salt is 1:0.8:0.1:0.1), add In the obtained homogeneous sol, stir at 120°C for about 2 hours to mix various metal salts evenly to form a black gel;

[0054] 3) Heat-treat the obtained black jelly in a drying oven at 180°C for 12 hours to obtain a black fluffy foamy solid;

[0055] 4) Grind the obtained foamy solid, pretreat it at 500°C for 5h in an air atmosphere, heat it up to 900°C for 10h, and grind it after cooling to room temperature to obtain LiNi 0.8 mn 0.1 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com