Grey cast iron platform surface polishing treatment system

A cast iron platform and surface polishing technology, which is applied to surface-polished machine tools, grinding/polishing equipment, and parts of grinding machine tools, etc. Accelerate the loss of gray graphite cast iron platform and other problems to achieve the effect of saving polishing cost, improving polishing effect and reducing polishing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

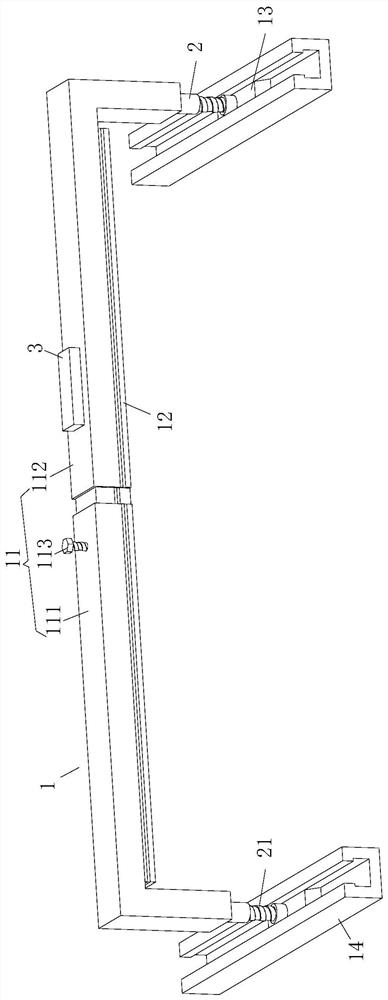

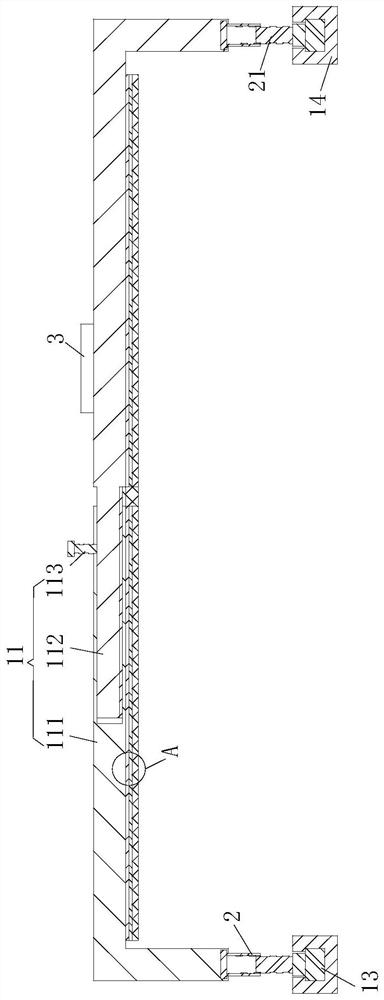

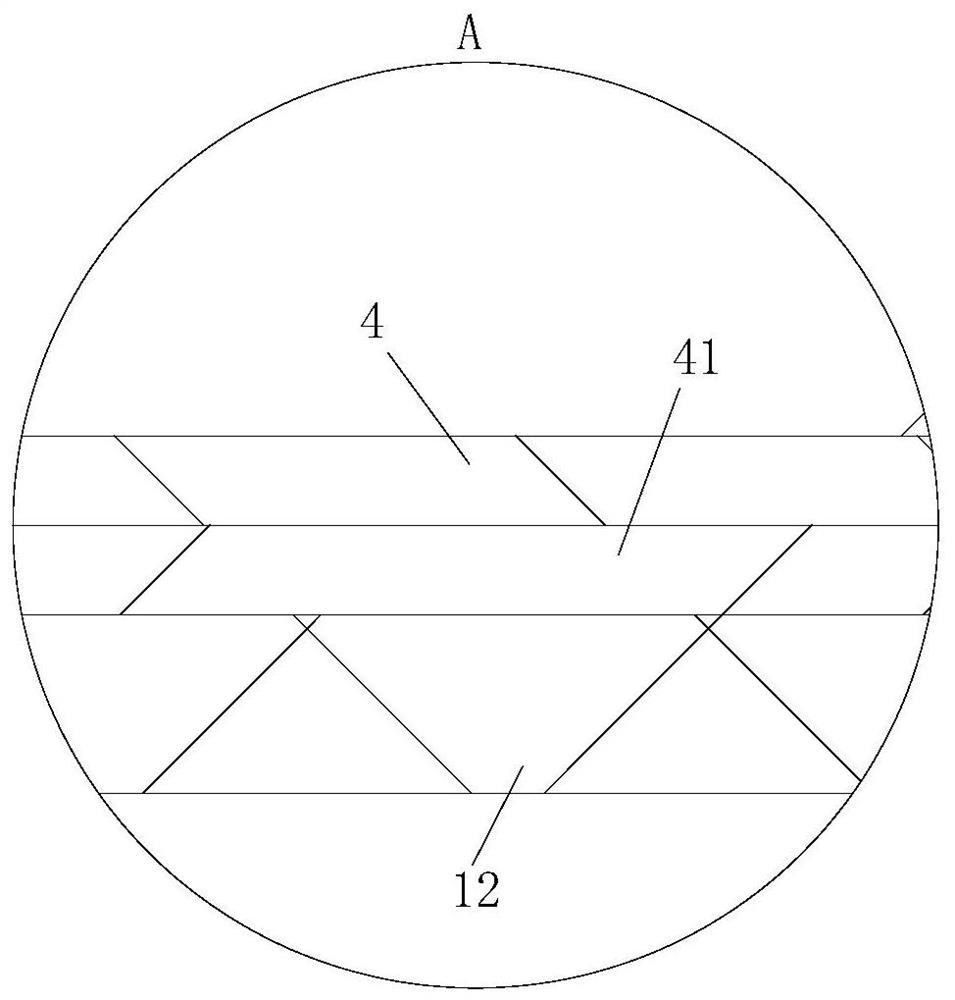

[0026]As an embodiment of the present invention, both sides of the bottom of the u-shaped frame 11 are rotatably connected with a rotating rod 2; the top of the slider 13 is fixedly connected with a threaded rod 21; Threaded connection; during work, when the lower surface of the cotton pad 12 cannot be in contact with the top of the gray black cast iron platform, by turning the rotating rod 2, adjust the amount that the threaded rod 21 extends into the rotating rod 2, thereby adjusting the height of the u-shaped frame 11 , until the lower surface of the cotton pad 12 can be in contact with the top of the gray black cast iron platform, thereby reducing the requirements for the installation position of the detection mechanism 1, improving the efficiency of the polishing work, and preventing the thickness of the gray black cast iron platform from reducing after multiple polishings, resulting in prior The cotton pad 12 on the installed detection mechanism 1 cannot be in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com