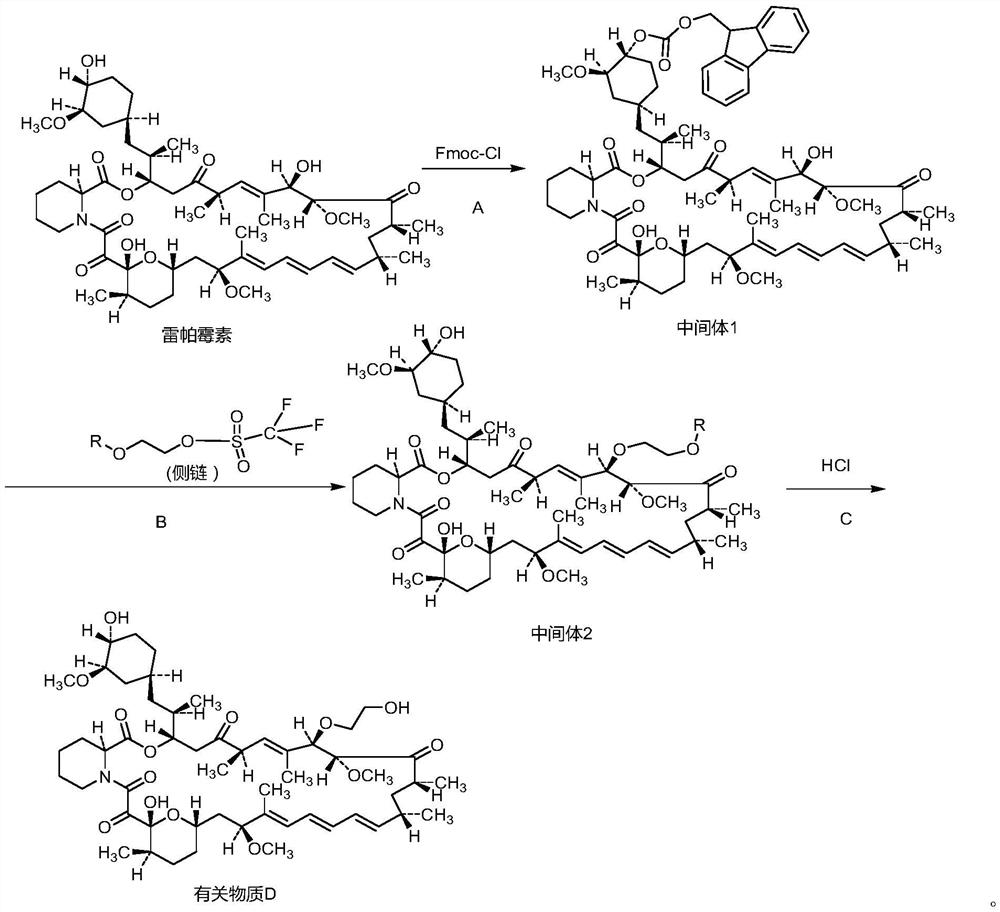

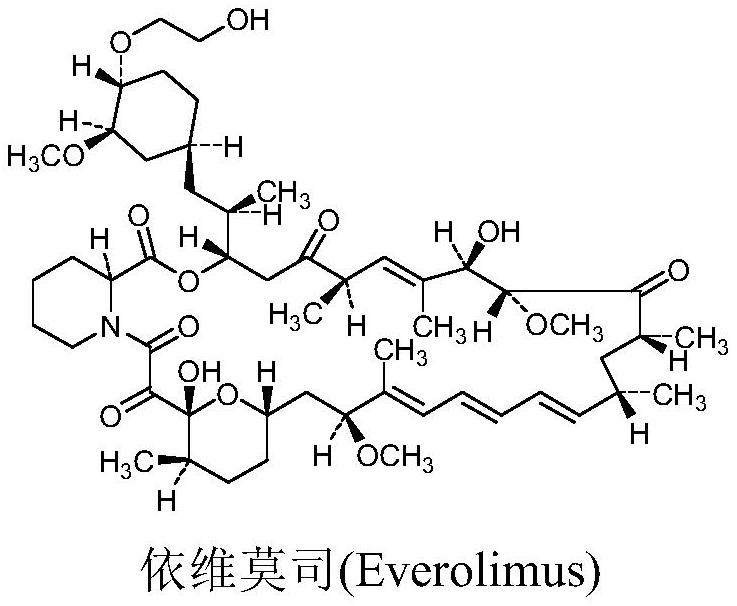

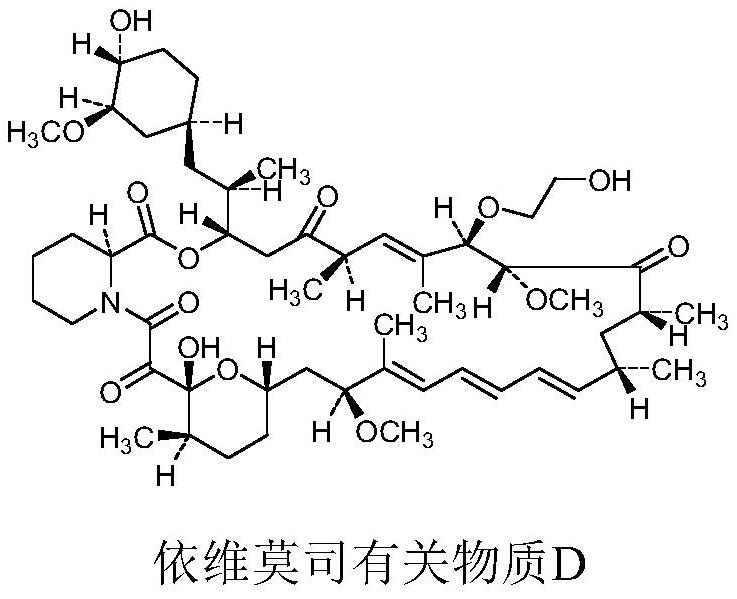

Synthesis method of everolimus related substance D

A related substance, everolimus technology, applied in the direction of organic chemistry, bulk chemical production, etc., can solve the problems of low yield, complex post-processing, etc., achieve high purity, simplify the purification process, and simplify the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The synthesis of embodiment 1 intermediate 1

[0055] Add 550ml of ethyl acetate into the round bottom flask, add 45.71g of rapamycin and 7.91g of pyridine under stirring, cool down to 0-5°C, add 15.52g of Fmoc-Cl, stir for 2 hours, raise the temperature to 25-30°C, keep warm Stir the reaction, TLC detects the reaction process until the rapamycin spots disappear, and the reaction is complete; add 150ml of purified water, stir for 20 minutes, extract and separate the liquid, extract the aqueous layer with 50ml ethyl acetate, combine the organic layers, and use 5% dilute Wash with 100ml of hydrochloric acid and 100ml of saturated brine, dry with anhydrous sodium sulfate for 4 hours, filter, and vacuum concentrate the filtrate to dryness at a temperature of 30-35°C, separate and purify on a silica gel column (respectively use petroleum ether / ethyl acetate=3 / 1 volume ratio and petroleum ether / ethyl acetate=2 / 1 volume ratio), the product eluate was concentrated in vacuo at 3...

Embodiment 2

[0056] The synthesis of embodiment 2 intermediate 1

[0057] Add 460ml of ethyl acetate to the round bottom flask, add 45.71g of rapamycin and 7.12g of pyridine under stirring, cool down to 0-5°C, add 13.58g of Fmoc-Cl, stir for 2 hours, heat up to 25-30°C, keep warm Stir the reaction, TLC detects the reaction process until the rapamycin spots disappear, and the reaction is complete; add 150ml of purified water, stir for 20 minutes, extract and separate the liquid, extract the aqueous layer with 50ml ethyl acetate, combine the organic layers, and use 5% dilute Wash with 100ml of hydrochloric acid and 100ml of saturated brine, dry with anhydrous sodium sulfate for 4 hours, filter, and vacuum concentrate the filtrate to dryness at a temperature of 30-35°C, separate and purify on a silica gel column (respectively use petroleum ether / ethyl acetate=3 / 1 volume ratio and petroleum ether / ethyl acetate=2 / 1 volume ratio), the product eluate was concentrated in vacuo at 30-35°C to drynes...

Embodiment 3

[0058] The synthesis of embodiment 3 intermediate 1

[0059] Add 640ml of ethyl acetate to the round bottom flask, add 45.71g of rapamycin and 8.70g of pyridine under stirring, cool down to 0-5°C, add 18.11g of Fmoc-Cl, stir for 2 hours, heat up to 25-30°C, keep warm Stir the reaction, TLC detects the reaction process until the rapamycin spots disappear, and the reaction is complete; add 150ml of purified water, stir for 20 minutes, extract and separate the liquid, extract the aqueous layer with 50ml ethyl acetate, combine the organic layers, and use 5% dilute Wash with 100ml of hydrochloric acid and 100ml of saturated brine, dry with anhydrous sodium sulfate for 4 hours, filter, and vacuum concentrate the filtrate to dryness at a temperature of 30-35°C, separate and purify on a silica gel column (respectively use petroleum ether / ethyl acetate=3 / 1 volume ratio and petroleum ether / ethyl acetate=2 / 1 volume ratio), the product eluate was concentrated in vacuo at 30-35°C to drynes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com