Preparation method of dielectric ceramic material

A technology for dielectric ceramics and powders, which is applied in the field of preparation of dielectric ceramic materials, can solve the problems of limited application, difficult application, and difficulty in meeting demands, and achieves the effect of low sintering temperature and high Qf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

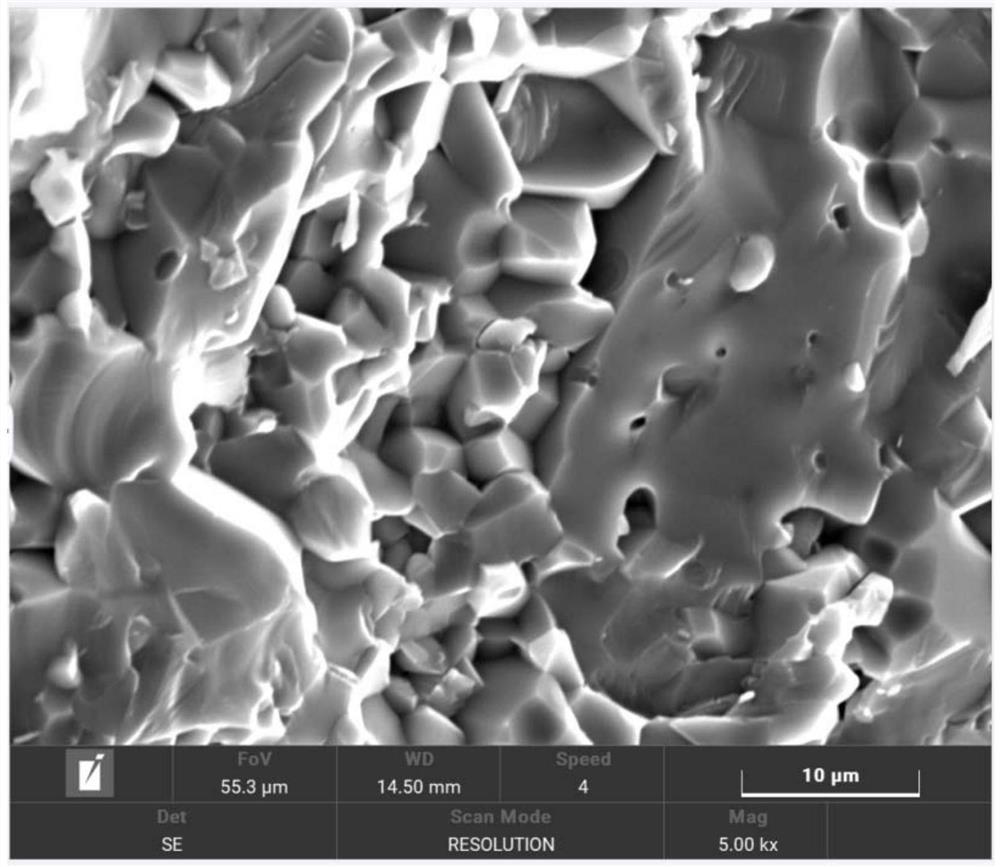

Image

Examples

Embodiment 1

[0040]A method for preparing a dielectric ceramic material, comprising the steps of:

[0041] Step S1: Use an electronic balance to weigh 407g ZnO powder, 512g Al 2 o 3 Powder, 77g TiO2 powder, 4gMnO 2 .

[0042] Step S2: Put the weighed powder into a ball mill, and then add 800 g of deionized water, and grind various raw materials into a slurry with a particle size of 0.9 μm. Most of the water in the slurry is squeezed out by filter press. Dry the slurry after pressure filtration, and then crush and sieve to obtain a powder with a particle size of less than 0.2mm. The powder is pre-fired, the pre-fire temperature is 1150°C, the pre-fire time is 5h, and the primary powder is obtained after pre-fire.

[0043] Step S3: Perform secondary mixing of the primary powder: add the primary powder and 50% deionized water equal to the weight of the primary powder into the ball mill, and use the ball mill to grind into a slurry with a particle size of 1.3 μm. The obtained slurry was ...

Embodiment 2

[0046] A preparation method of a dielectric ceramic material, except that the sintering temperature is 1330° C. in the experimental steps, the rest are the same as in Example 1.

Embodiment 3

[0048] A preparation method of a dielectric ceramic material, except that the sintering temperature is 1360° C. in the experimental steps, the rest are the same as in Example 1.

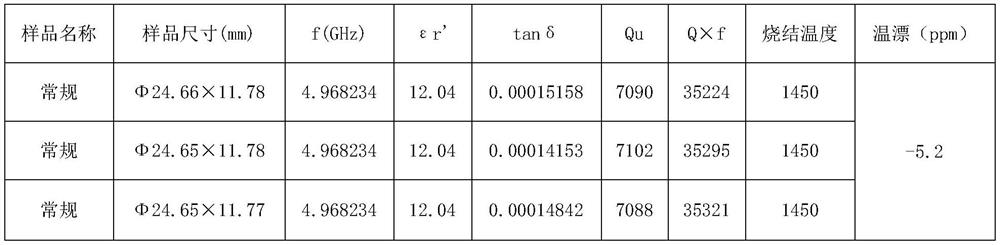

[0049] Table 1. Performance data of experimental samples of the same size

[0050] Example number εr Qf / GHz ppm / °C Sintering temperature / ℃ Comparative example 1 8.5 145688 -79 1450 Comparative example 2 11.56 139582 -12.6 1350 Comparative example 3 12.18 122549 -5 1350 Example 1 11.89 90886 25.6 1300 Example 2 12.26 126035 0.2 1330 Example 3 12.32 118879 6.3 1360

[0051] Microwave dielectric ceramic is a dielectric material used in the microwave frequency band. Under the action of an external electric field, its plan strength changes, and electric energy is transmitted and stored in an inductive manner. In recent years, the rapid progress of information processing technology and electronic information digitization technology...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com