A special fertilizer for corn and peanut intercropping and a cultivation method for maintaining soil organic carbon balance

A cultivation method and a special fertilizer technology, applied in fertilization methods, grain cultivation, soil preparation methods, etc., can solve problems affecting crop growth, weakening of crop root systems, and decline in disease prevention functions, so as to increase ventilation and light transmittance, and improve crop growth. Promote and improve the effect of yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

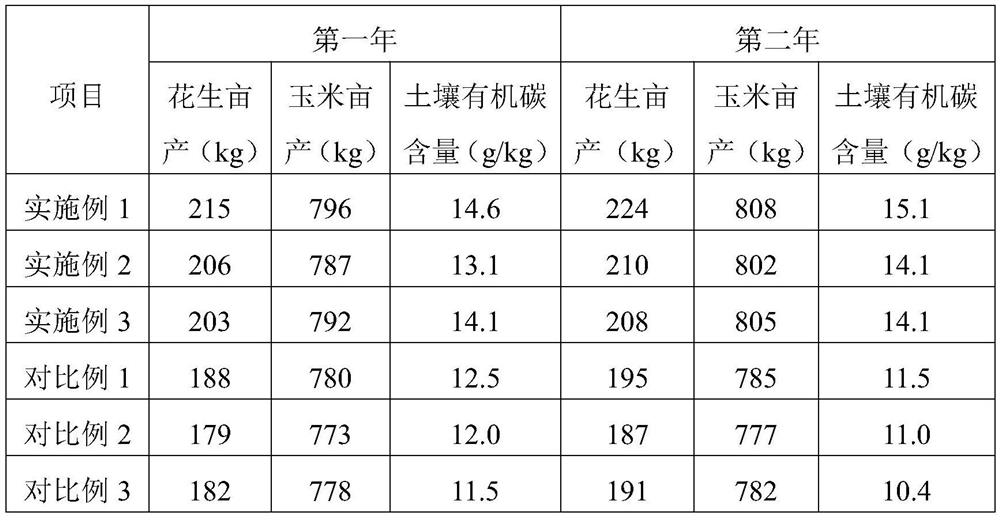

Examples

Embodiment 1

[0038] Get 45 parts of coated urea (wherein, fly ash and polyvinyl alcohol are coating materials, and the two consumption accounts for 20% of the total weight of coated urea, and the mass ratio of fly ash and polyvinyl alcohol is 3:1, and the two The amount of cyanamide accounts for 3% of the total weight of the coated urea), 25 parts of superphosphate, 18 parts of ammonium sulfate, 4 parts of fermented soybean meal, 22 parts of bentonite, 1.2 parts of sodium molybdate, 6 parts of borax, 8 parts of humic acid , 6 parts of ammonium dihydrogen phosphate, 4 parts of plant ash, and 2 parts of zinc sulfate heptahydrate. All the weighed raw materials were placed in a mixer for 5 minutes, dried in an oven at 60°C for 5 hours, and granulated by a granulator to obtain a special fertilizer for corn and peanut intercropping rotation.

Embodiment 2

[0040] Get 40 parts of coated urea (wherein, fly ash and polyvinyl alcohol are coating materials, and the two consumption accounts for 20% of the total weight of coated urea, and the mass ratio of fly ash and polyvinyl alcohol is 3:1, and the two The amount of cyanamide accounts for 3% of the total weight of the coated urea), 30 parts of superphosphate, 15 parts of ammonium sulfate, 5 parts of fermented soybean meal, 20 parts of bentonite, 1.5 parts of sodium molybdate, 5 parts of borax, 10 parts of humic acid , 5 parts of ammonium dihydrogen phosphate, 5 parts of plant ash, and 1 part of zinc sulfate heptahydrate. All the weighed raw materials were placed in a mixer for 5 minutes, dried in an oven at 60°C for 5 hours, and granulated by a granulator to obtain a special fertilizer for corn and peanut intercropping rotation.

Embodiment 3

[0042] Get 50 parts of coated urea (wherein, fly ash and polyvinyl alcohol are coating materials, and the two consumption accounts for 20% of the total weight of coated urea, and the mass ratio of fly ash and polyvinyl alcohol is 3:1, and the two The amount of cyanamide accounts for 3% of the total weight of the coated urea), 20 parts of superphosphate, 20 parts of ammonium sulfate, 3 parts of fermented soybean meal, 30 parts of bentonite, 1 part of sodium molybdate, 8 parts of borax, and 5 parts of humic acid , 10 parts of ammonium dihydrogen phosphate, 3 parts of plant ash, and 3 parts of zinc sulfate heptahydrate. All the weighed raw materials were placed in a mixer for 5 minutes, dried in an oven at 60°C for 5 hours, and granulated by a granulator to obtain a special fertilizer for corn and peanut intercropping rotation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com