Preparation method and application of three-dimensional nitrogen-phosphorus-sulfur doped honeycomb carbon

A honeycomb, sulfur-doped technology, applied in the manufacture of hybrid/electric double layer capacitors, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as high cost, equipment corrosion, and environmental pollution, and achieve Large energy density, reduced waste liquid generation, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

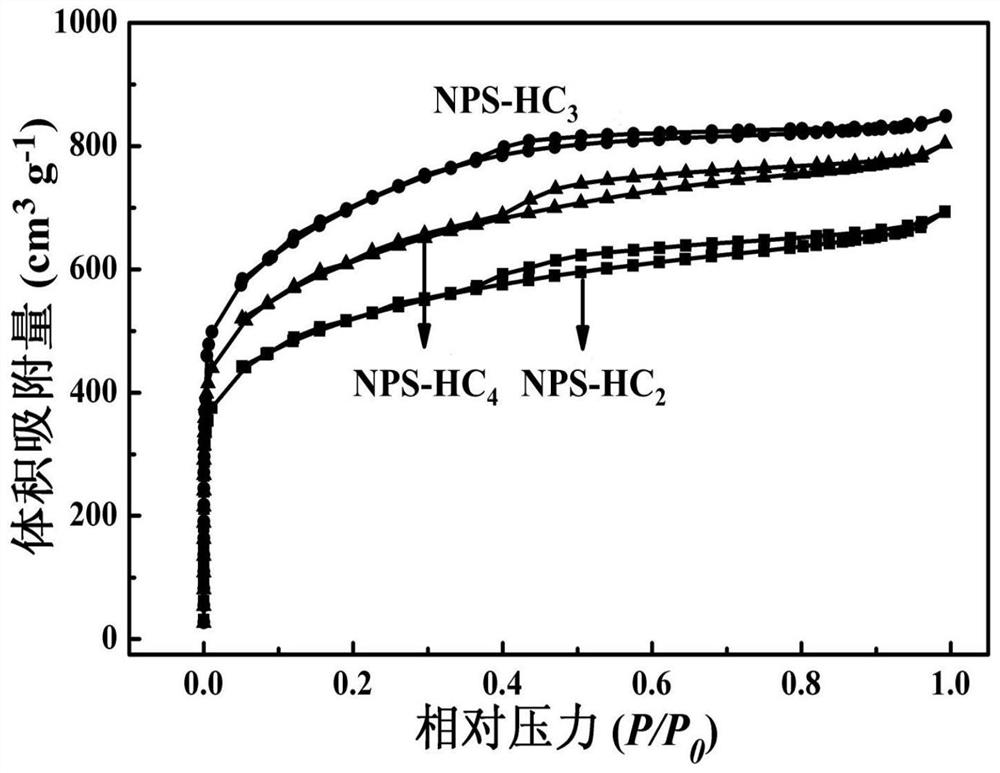

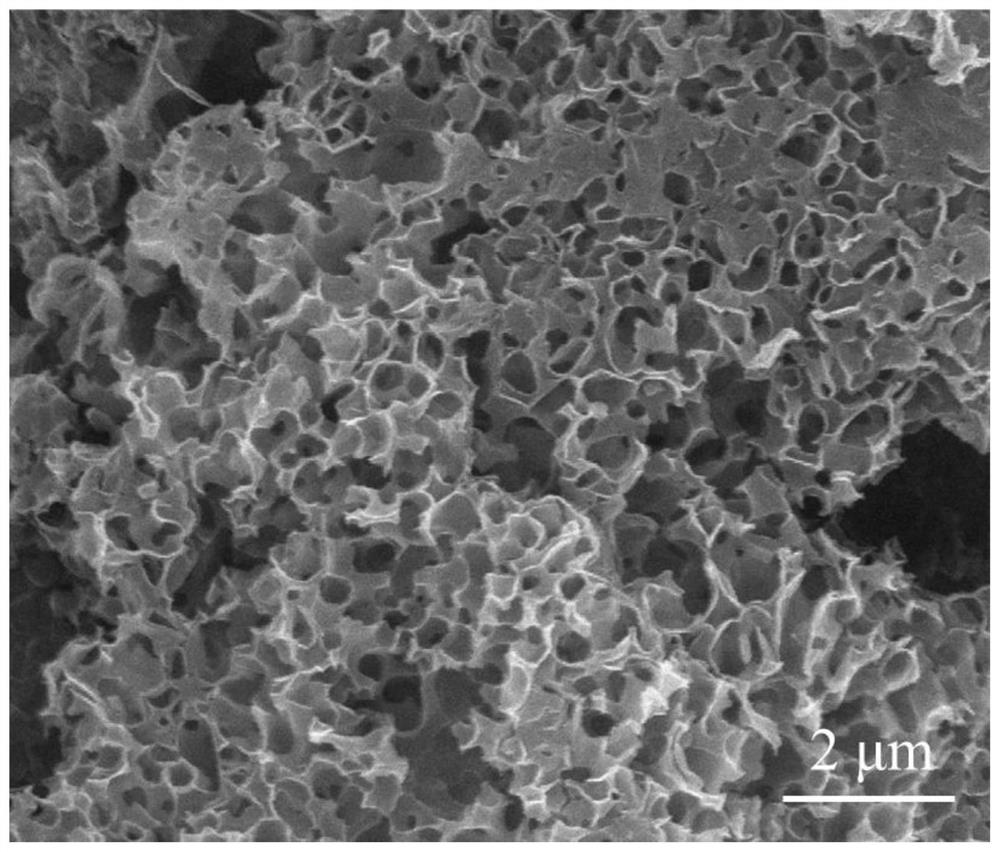

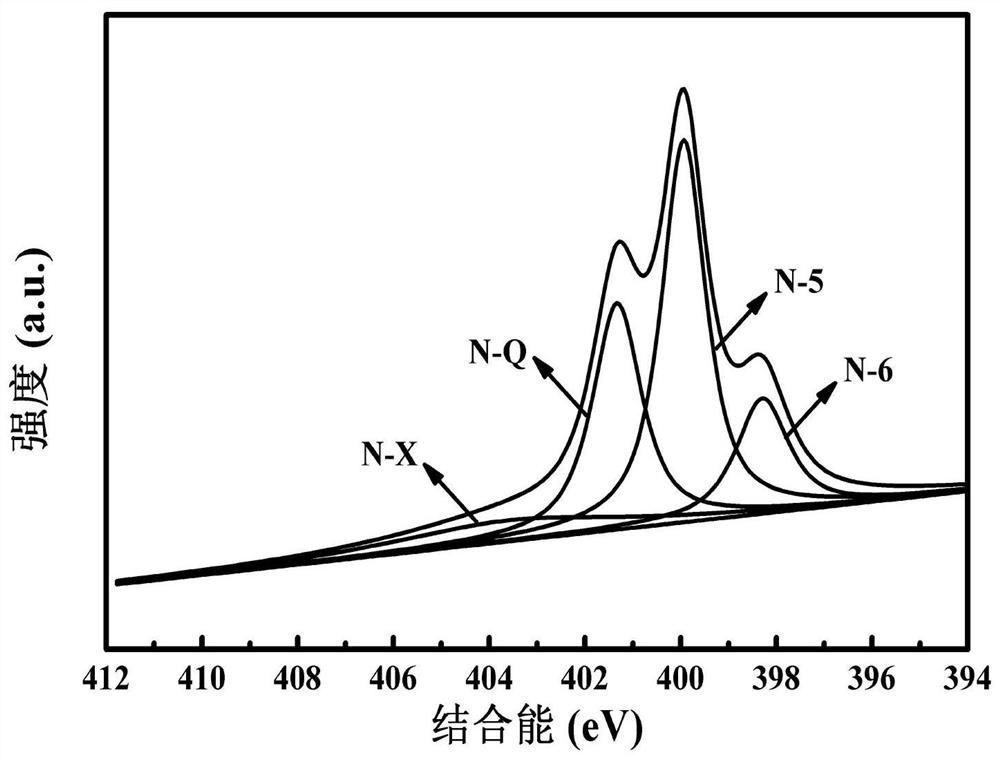

[0034] The present invention proposes that the specific preparation process of the three-dimensional nitrogen, phosphorus and sulfur doped honeycomb carbon constructed by two-dimensional carbon nanosheets is as follows:

[0035] S1: Preparation of nitrogen source and phosphorus source precursors: first heat deionized water to 60°C, add melamine with constant temperature stirring, slowly add phytic acid after dissolving, react for 6 hours, freeze, filter, and dry to obtain nitrogen source and phosphorus source Precursor;

[0036] S2: Pretreatment of reactants: Grinding and uniformly mixing phenanthrene, potassium sulfate, oxalic acid and the product obtained in step S1 according to a certain mass ratio;

[0037] S3: Transfer the reactants obtained in step S2 to a tube furnace, react under the protection of argon, and allow to cool to room temperature, and remove impurities to obtain a three-dimensional nitrogen, phosphorus and sulfur doped honeycomb constructed of two-dimension...

Embodiment 2

[0041] The present invention proposes that the specific preparation process of the three-dimensional nitrogen, phosphorus and sulfur doped honeycomb carbon constructed by two-dimensional carbon nanosheets is as follows:

[0042] S1: Preparation of nitrogen source and phosphorus source precursors: first heat deionized water to 70°C, add melamine with constant temperature stirring, slowly add phytic acid after dissolving, react for 9 hours, freeze, filter, and dry to obtain nitrogen source and phosphorus source Precursor;

[0043] S2: Pretreatment of reactants: Grinding and uniformly mixing phenanthrene, potassium sulfate, activator and the product obtained in step S1 according to a certain mass ratio;

[0044] S3: Transfer the reactants obtained in step S2 to a tube furnace, react under the protection of argon, and allow to cool to room temperature, and remove impurities to obtain a three-dimensional nitrogen, phosphorus and sulfur doped honeycomb constructed of two-dimensional...

Embodiment 3

[0048] The present invention proposes the specific preparation process of the three-dimensional nitrogen, phosphorus and sulfur doped honeycomb carbon constructed of two-dimensional carbon nanosheets as follows:

[0049] S1: Preparation of nitrogen source and phosphorus source precursors: first heat deionized water to 80°C, stir at constant temperature and add melamine, slowly add phytic acid after dissolving, react for 12 hours, freeze, filter, and dry to obtain nitrogen source and phosphorus source Precursor;

[0050] S2: Pretreatment of reactants: Grinding and uniformly mixing phenanthrene, potassium sulfate, activator and the product obtained in step S1 according to a certain mass ratio;

[0051] S3: Transfer the reactants obtained in step S2 to a tube furnace, react under the protection of argon, and allow to cool to room temperature, and remove impurities to obtain a three-dimensional nitrogen, phosphorus and sulfur doped honeycomb constructed of two-dimensional carbon nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com