Method for modifying surface of lithium transition metal oxide positive electrode material

A lithium transition metal and positive electrode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of surface BET increase, battery impedance increase, uneven coating, etc., achieve small interface BET and improve high-voltage resistance performance , reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

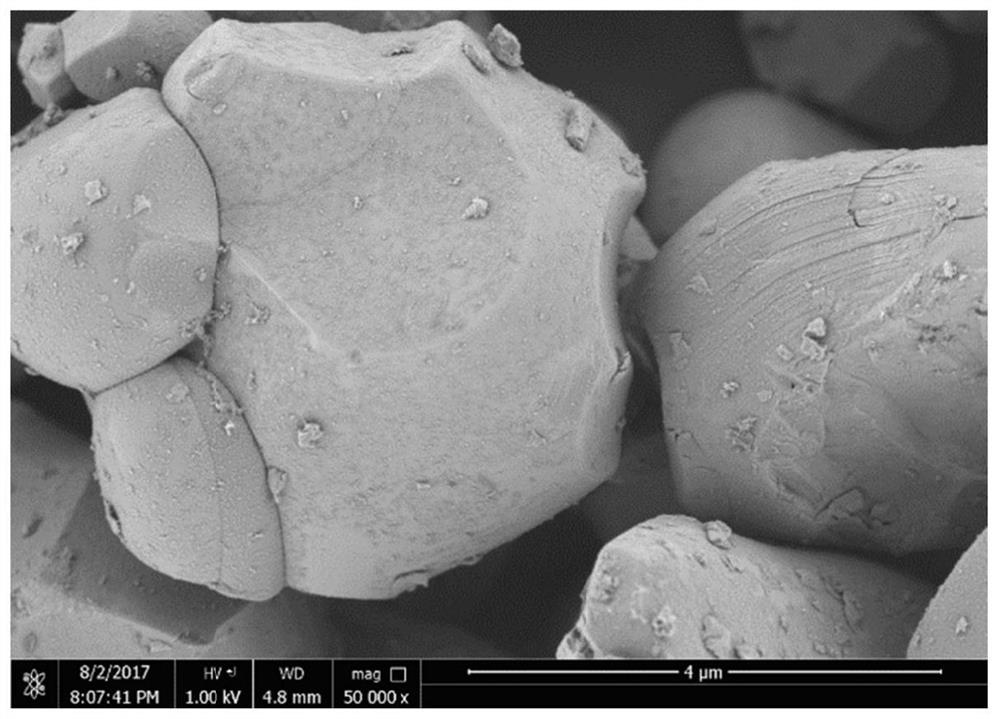

[0040] In this example, a surface-modified lithium transition metal oxide positive electrode material was prepared, and the specific process was as follows:

[0041] (1) Pour 50kg of deionized water into the washing kettle, then add the first additive LiPO to the deionized water 3 and the second additive Al 2 (SO 4 ) 3 sulfuric acid solution, Al in the second additive 3+ The concentration is 0.2mol / L, stir evenly, and then follow the LiCoO 2 The solid-to-liquid mass ratio of the first-fired powder (particle size Dv50 is 8 μm) and deionized water is 1:0.8, and the amount of the first additive added is LiCoO 2 0.02wt% of the mass of the first-fired powder, 200r / min high-speed stirring to form a uniform first slurry;

[0042] (2) Add TiO dropwise to the first slurry 2+ Concentration of 0.2mol / L TiOSO 4 Sulfuric acid solution, and control the dropping time for 5 minutes. After the dropping is completed, continue to stir at a high speed of 500r / min for 10 minutes to obtain t...

Embodiment 2

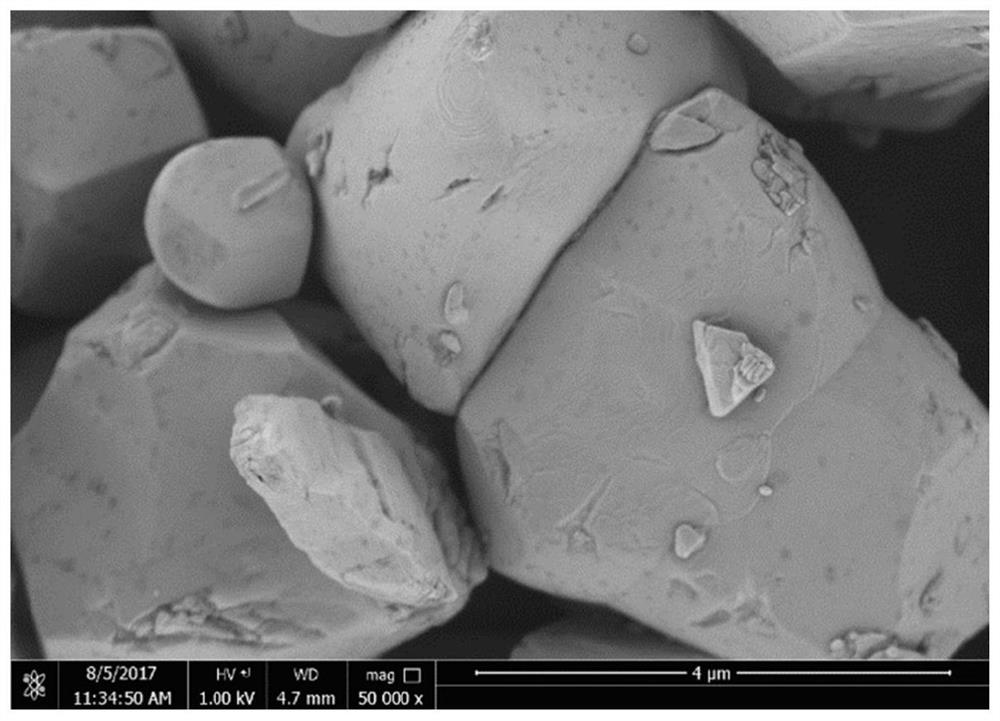

[0048] In this example, a surface-modified lithium transition metal oxide positive electrode material was prepared, and the specific process was as follows:

[0049] (1) Pour 50kg of deionized water into the washing kettle, then add the first additive Li to the deionized water 3 PO 4 and the second additive Al 2 Cl 3 sulfuric acid solution, Al in the second additive 3+ The concentration is 0.1mol / L, stir evenly, and then follow the LiCoO 2 The solid-to-liquid mass ratio of the first-fired powder (particle size Dv50 is 10 μm) and deionized water is 1:3, and the amount of the first additive added is LiCoO 2 0.01wt% of the mass of the first-fired powder, 300r / min high-speed stirring to form a uniform first slurry;

[0050] (2) Add TiO dropwise to the first slurry 2+ Concentration of 0.1mol / L TiOSO 4 Sulfuric acid solution, and control the dropwise addition time for 7min, after the dropwise addition is completed, continue to stir at a high speed of 500r / min for 10min to obt...

Embodiment 3

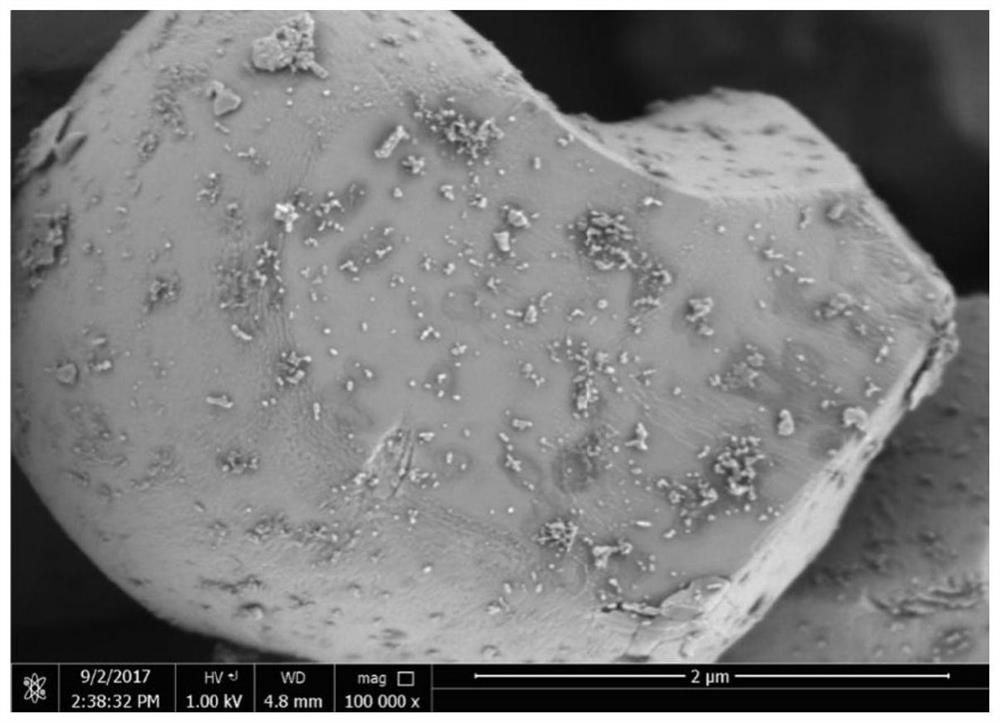

[0055] In this example, a surface-modified lithium transition metal oxide positive electrode material was prepared, and the specific process was as follows:

[0056] (1) Pour 50kg of deionized water into the washing kettle, then add the first additive LiPO to the deionized water 3 and the second additive Y 2 (SO 4 ) 3 sulfuric acid solution, Y in the second additive 3+ The concentration is 0.05mol / L, stir evenly, and then add LiNi according to the solid-liquid mass ratio of high-nickel ternary material primary sintered powder and deionized water as 1:5 0.85 co 0.10 mn 0.05 o 2 (Particle diameter Dv50 is 3 μm) powder, the addition amount of the first additive is 0.01wt% of the mass of the added first-burned powder, 200r / min high-speed stirring forms the uniform first slurry;

[0057] (2) Add ZrO dropwise to the first slurry 2- ZrOSO with a concentration of 0.05mol / L 4 Sulfuric acid solution, and control the dropwise addition time for 6min. After the dropwise addition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com