MXene-based composite material as well as preparation method and application thereof

A composite material and substrate technology, applied in the coating and other directions, can solve the problems such as the inability to meet the multi-factor stimulus response, the inability to meet the application requirements of the actuator, and achieve the effects of excellent mechanical properties, large deformation, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

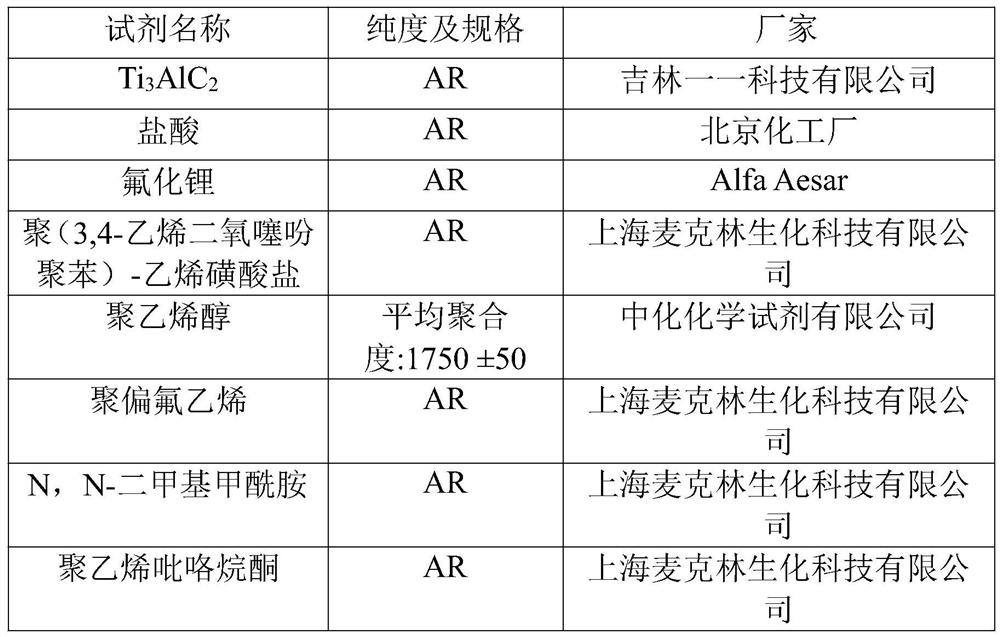

[0034] Step 1: Preparation of polyvinylidene fluoride (PVDF) substrate: Dissolve PVDF and polyvinylpyrrolidone (PVP) at a weight ratio of 20:1 in N,N-dimethylformamide (DMF) at a concentration of 25 mg / mL of the mixed solution, fully stirred at room temperature for 3 hours, took 10mL of the mixed solution in a watch glass with a diameter of 60mm, put it in a vacuum oven at 80°C and heated and cured for 1 hour, and a transparent PVDF substrate could be obtained on the watch glass;

[0035] Step 2: Prepare MXene-PEDOT / PSS mixed solution: mix 10mol / L monolithic MXene solution with PEDOT:PSS (poly(3,4-ethylenedioxythiophene polyphenylene)-ethylene sulfonate), polyvinyl alcohol Mix according to the volume ratio of 5:5:2 and carry out stirring and ultrasonication for 1h to prepare a mixed solution;

[0036] Step 3: Take 5 mL of the MXene-PEDOT / PSS mixed solution obtained in Step 2 and apply it to the watch glass covered with PVDF substrate in Step 1, and dry it in an oven at 60°C f...

Embodiment 2

[0039] Step 1: Prepare PVDF substrate: Dissolve PVDF and polyvinylpyrrolidone (PVP) at a weight ratio of 20:1 in N,N-dimethylformamide (DMF) to prepare a mixed solution with a concentration of 25mg / mL at room temperature Fully stir for 3 hours under high temperature, take 10mL of the mixed solution in a watch glass with a diameter of 60mm, put it in a vacuum oven at 80°C and heat and cure for 1 hour, and a transparent PVDF substrate can be obtained on the watch glass;

[0040] Step 2: Prepare MXene-PEDOT:PSS mixed solution: Mix 10mol / L monolithic MXene solution with PEDOT:PSS and polyvinyl alcohol in a ratio of 4:1:1 by volume and stir and sonicate for 1h to prepare the mixed solution solution;

[0041] Step 3: Take 5 mL of MXene-PEDOT:PSS mixed solution and apply it on the watch glass, and dry it in an oven at 60°C for 1 hour to obtain the MXene composite material;

[0042] Step 4: After drying, the watch glass is cooled, and the double-layer film is peeled off from the watc...

Embodiment 3

[0044] Step 1: Prepare PVDF substrate: Dissolve PVDF and polyvinylpyrrolidone (PVP) at a weight ratio of 20:1 in N,N-dimethylformamide (DMF) to prepare a mixed solution with a concentration of 25mg / mL at room temperature Fully stir for 3 hours under high temperature, take 10mL of the mixed solution in a watch glass with a diameter of 60mm, put it in a vacuum oven at 80°C and heat and cure for 1 hour, and a transparent PVDF substrate can be obtained on the watch glass;

[0045] Step 2: Prepare MXene-PEDOT:PSS mixed solution: Mix 10mol / L monolithic MXene solution with PEDOT:PSS and polyvinyl alcohol in a ratio of 3:2:1 by volume, stir and sonicate for 1h to prepare the mixed solution solution;

[0046] Step 3: Take 5 mL of MXene-PEDOT:PSS mixed solution and apply it to the above-mentioned watch glass, and dry it in an oven at 60°C for 1 hour to obtain the MXene composite material;

[0047] Step 4: After drying, the watch glass is cooled, and the double-layer film is peeled off ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com