High-cohesiveness anti-cracking epoxy powder composition and preparation method thereof

An epoxy powder, high-adhesion technology, used in non-polymer adhesive additives, epoxy resin adhesives, adhesive types, etc., can solve problems such as affecting electrical properties, chip corrosion, product cracking, etc. Enhance the anti-delamination ability, enhance the bonding performance, and facilitate the processing and use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below by specific embodiment content of the present invention is described in further detail, and following embodiment is descriptive, not limiting, can not limit protection scope of the present invention with this.

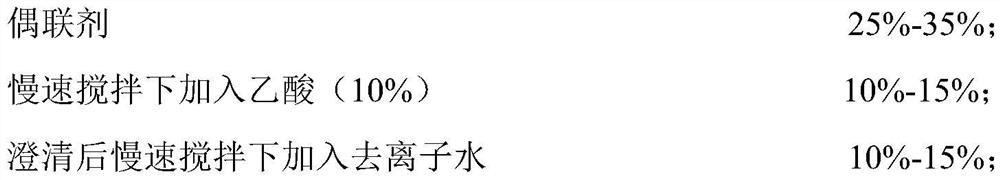

[0033] Each component is accurately weighed, added to a high-speed mixer and mixed evenly, the mixed material is melted and mixed in a twin-screw extruder at 170 degrees, the tablet is cooled and crushed, and the appropriate particle size is sieved to test the product performance index . The addition ratio of each embodiment and comparative example is as follows, and formula unit is mass fraction.

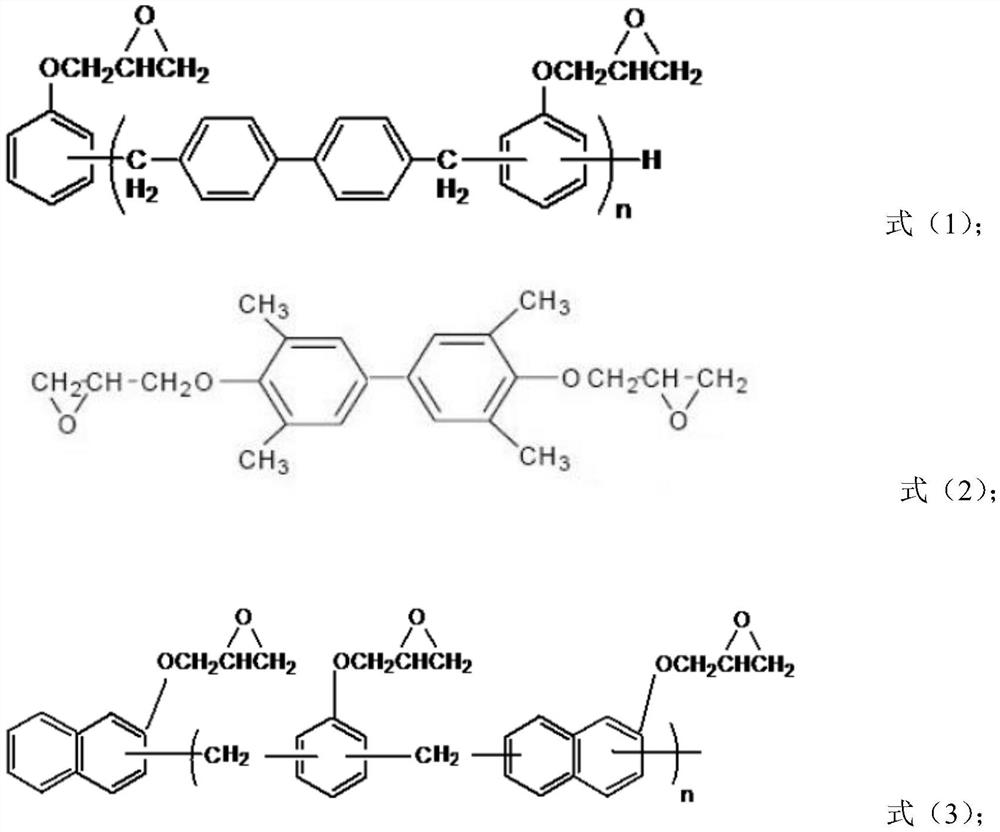

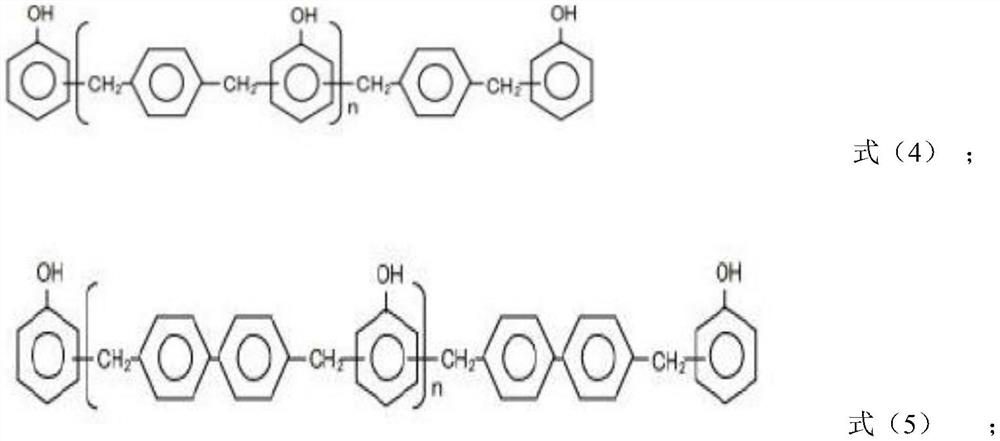

[0034] Wherein self-made special epoxy resin 1 is prepared as follows:

[0035] Add 45kg of tetrafunctional glycidylamine epoxy resin (TGDDM) into the reaction kettle, and heat the resin to 100°C. Add 4.5kg of oxalic acid and stir for 1 hour to fully mix the oxalic acid and epoxy resin. Add accelerator TPP, heat up to 150°C, vacuumize, and fully react for 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com