Preparation method of organic/inorganic hybrid electron transport layer with porous structure

An electron transport layer and organic technology, applied in the manufacture/processing of organic semiconductor devices, organic semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems of unfavorable commercial application of organic solar cells and restrictions on wide application, and achieve improvement Effects of charge extraction efficiency, multiple charge transport channels, and increased ohmic contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

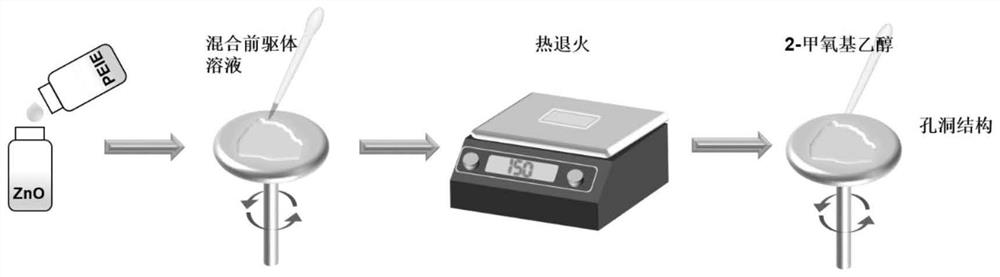

[0022] Step 1, dissolving zinc acetate dihydrate (2g) in 10mL of 2-methoxyethanol, and adding 0.28mL of ethanolamine to aid dissolution, fully stirring, and preparing a clear and transparent zinc oxide precursor solution;

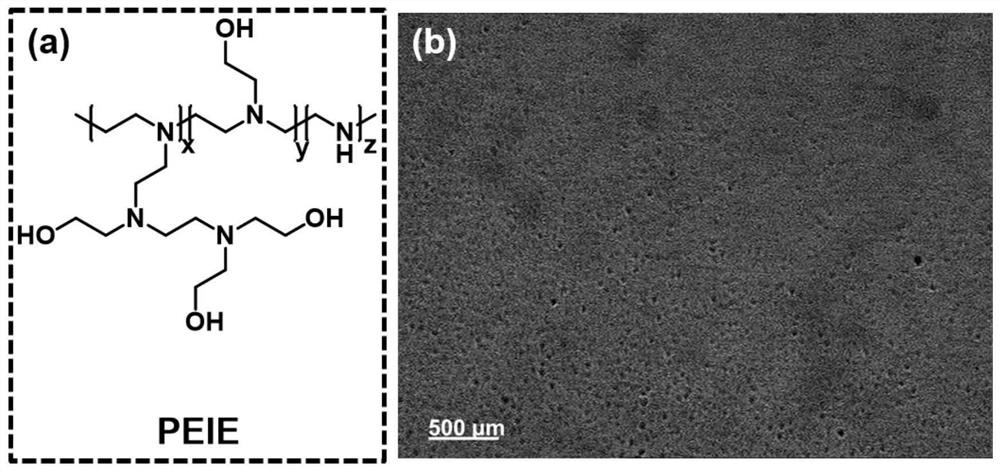

[0023] Step 2, dilute the 35wt% PEIE aqueous solution to 0.5% with 2-methoxyethanol, and use the mixed solution of the zinc oxide precursor obtained in step 1 as the electron transport layer solution;

[0024] Step 3: Spin coating with a homogenizer, the spin coating substrate is ITO, the spin coating speed is 5000rpm, and the spin coating time is 30s. After the end, perform thermal annealing at 150°C for 40 minutes;

[0025] Step 4, after annealing, cool to room temperature, and spin-coat with 2-methoxyethanol to clean at a speed of 3000rpm, and spin-coat for 30s;

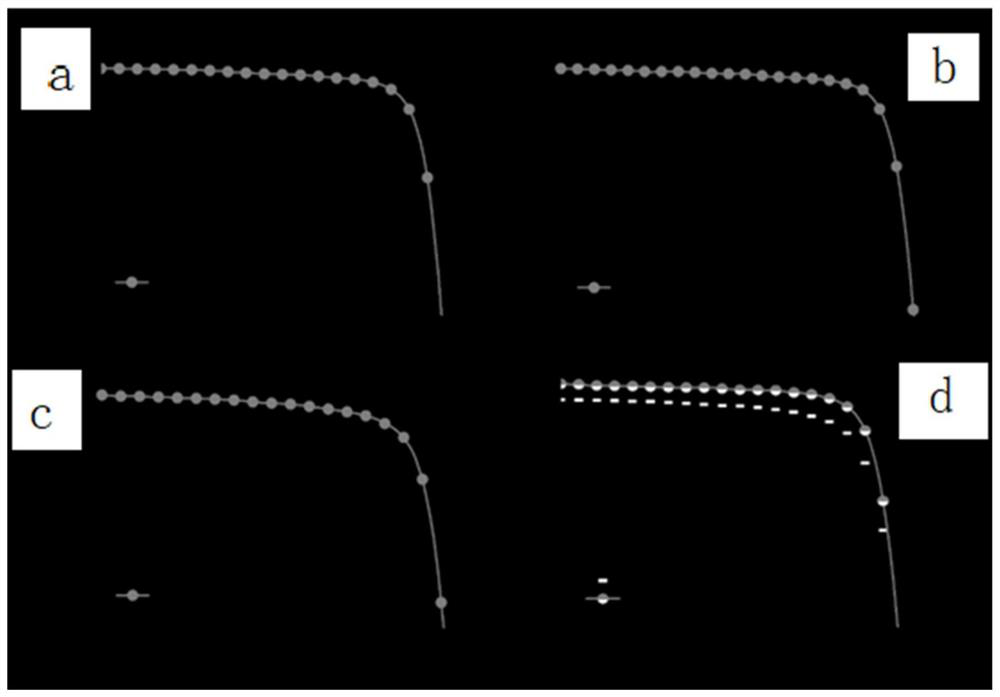

[0026] Step 5, move the substrate prepared with the electron transport layer into the glove box to spin-coat the active layer PBDB-T / DTPPSe-2F, PM6 / Y6, PTB7-Th / PC 71 BM, finally evaporated MoO...

Embodiment 2

[0034] Step 1, dissolving zinc acetate dihydrate (2g) in 10mL of 2-methoxyethanol, and adding 0.28mL ethanolamine to aid in dissolution, stirring thoroughly, and preparing a clear and transparent zinc oxide precursor solution;

[0035] Step 2, dilute the high-concentration PEIE aqueous solution to 0.5% with 2-methoxyethanol, and use the mixed solution of the zinc oxide precursor obtained in step 1 as the electron transport layer solution;

[0036] Step 3: Spin coating with a homogenizer, the spin coating substrate is ITO, the spin coating speed is 5000rpm, and the spin coating time is 30s. After the end, perform thermal annealing at 150°C for 40 minutes;

[0037] Step 4, after annealing, cool to room temperature, and spin-coat with 2-methoxyethanol to clean at a speed of 3000rpm, and spin-coat for 30s;

[0038] Step 5, move the substrate prepared with the electron transport layer into an indoor fume hood to spin-coat the active layer PBDB-T / DTPPSe-2F, and finally evaporate MoO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com