Metal nanoparticle enhanced semiconductor film for functionalized textiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

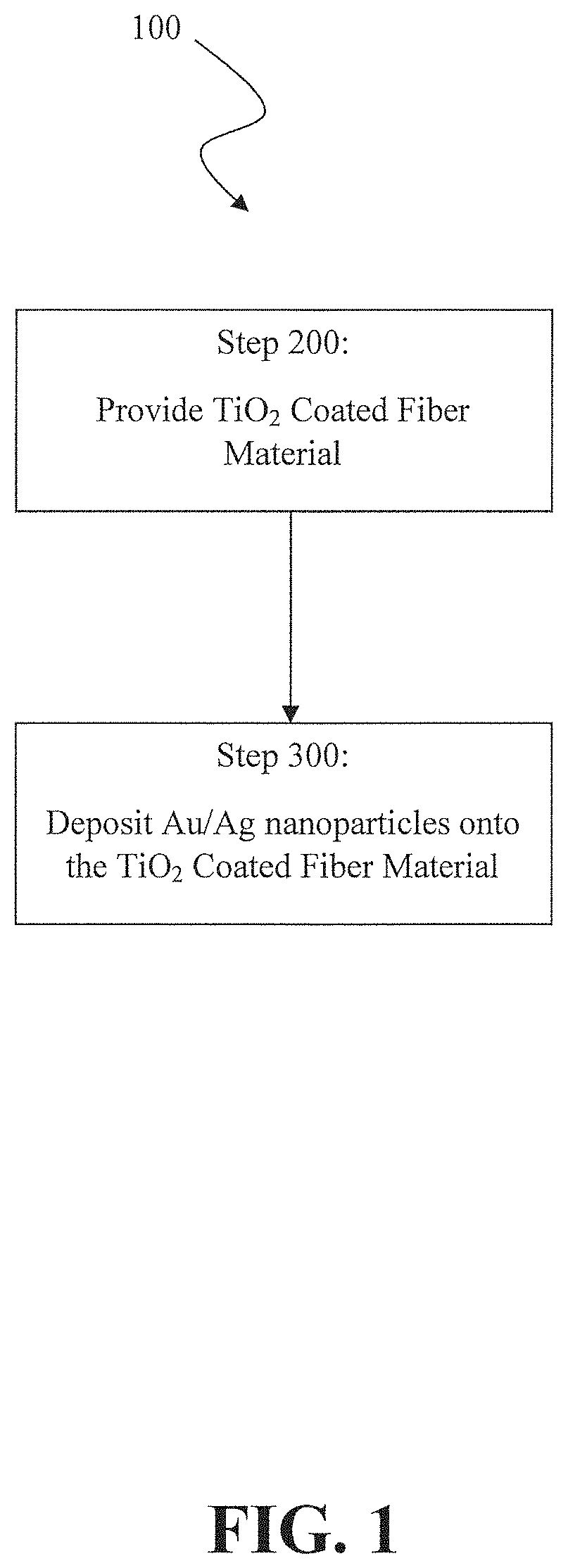

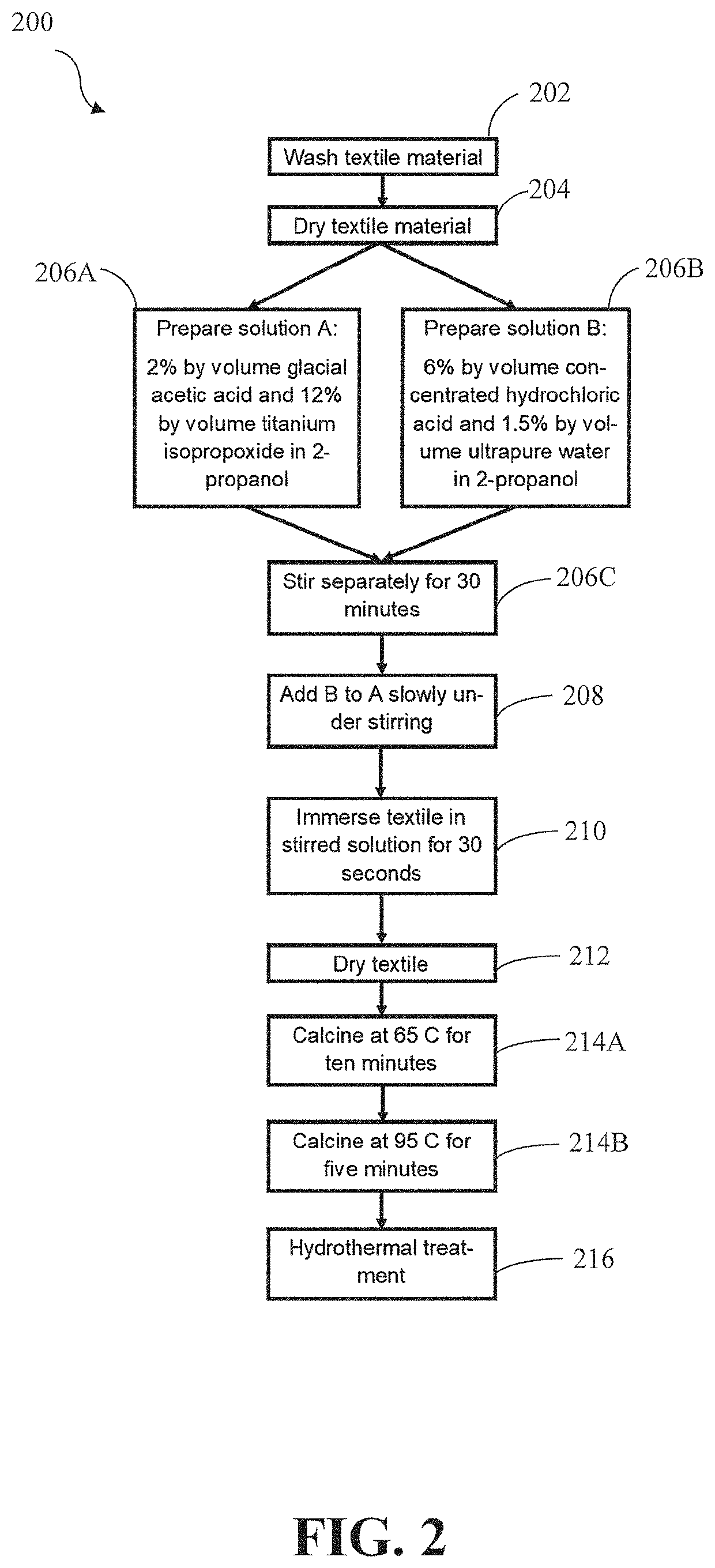

Method used

Image

Examples

example 1

Protective Equipment (PPE), Gloves, Gowns, Masks, Surgical and Facility Draping

[0069]The present example demonstrates the utility of the present invention for providing personal protective equipment (PPE), fabricated with the herein described functionalized textile materials. Personal protective equipment (PPE) refers to protective clothing, helmets, gloves, face shields, goggles, facemasks and / or respirators or other equipment designed to protect the wearer from injury or the spread of infection or illness. In particular applications, the infection and / or illnesses may comprise infections or illnesses caused by bacteria, viruses (including corona virus), fungus and other related infectious agents.

[0070]PPE is commonly used in health care settings such as hospitals, doctor's offices and clinical labs. When used properly, PPE acts as a barrier between infectious materials such as viral and bacterial contaminants and your skin, mouth, nose, or eyes (mucous membranes). The barrier has ...

example 2

of a PPE Device to include a Metal Nanoparticle Enhanced Semiconductor Film

[0080]The present example demonstrates that the present process and treatment may be provided onto the surface of an existing article of personal protective equipment, such as a mask.

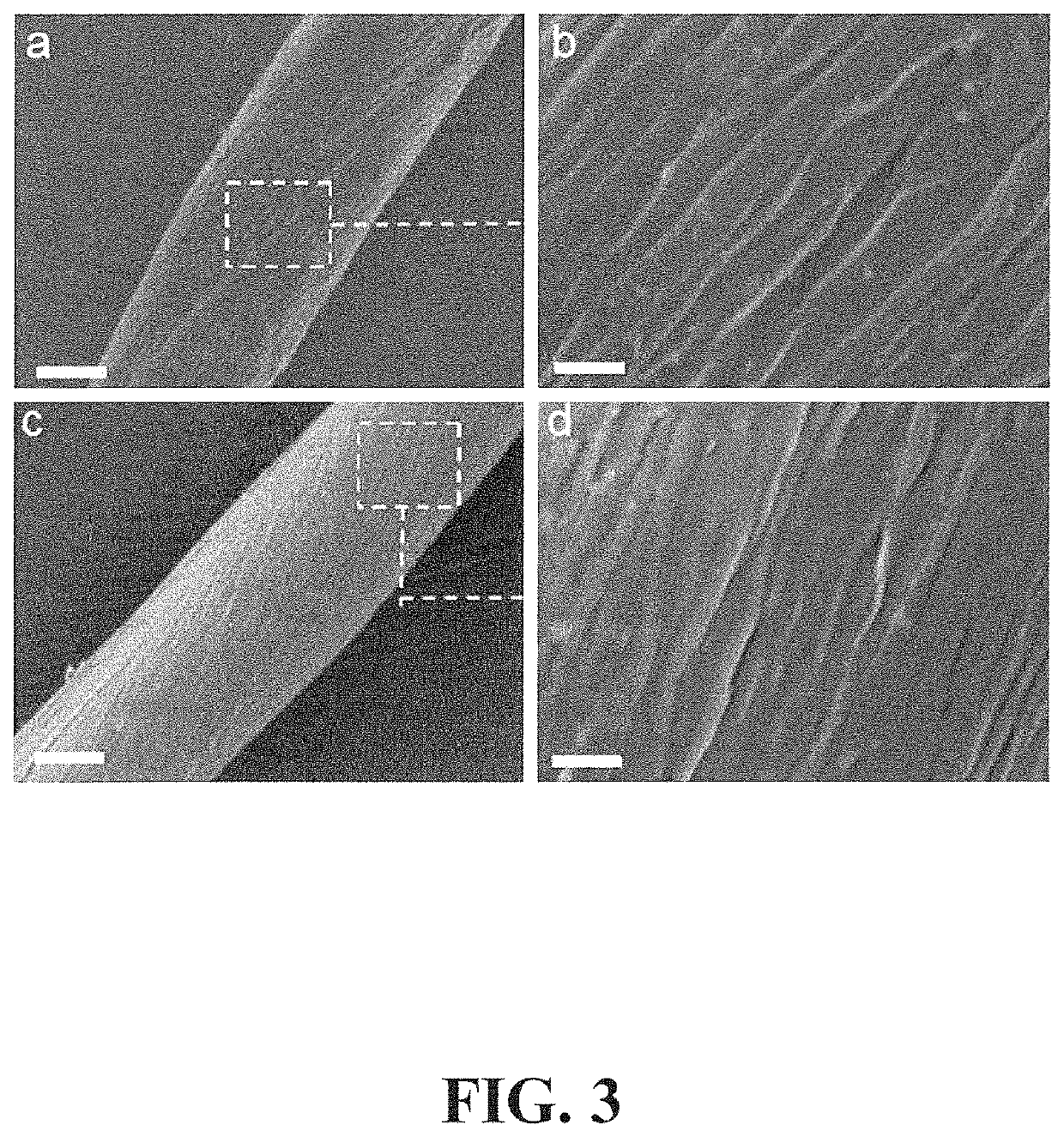

[0081]Conventional commercially available face masks made of a tight-weave cotton, were treated according to the methods described herein to include a thin, 1 mM, Ag—TiO2 film or an Au—TiO2 film. These treated cotton masks were then examined for stability of the deposited thin film.

[0082]The results demonstrated that the methods used provided for the successful deposition of a thin semi-conductive layer and growth of a uniform layer of metal nanostructured particles to the surface.

[0083]As demonstrated in the following examples, cotton materials / textiles treated as described herein were also observed to be stable and resistant to degradation and / or deterioration from multiple machine washings with fabric detergents, did not demon...

example 3

and Reusable Personal Protective Equipment

[0084]The present example demonstrates that the articles treated to include the functionalized surfaces are stable, may be washed using conventional methods, such as in a conventional washing machine with detergents, and may also be sterilized after use with white or ultraviolet light.

[0085]After use of a mask, for example, that has been treated to include the herein described thin film semiconductor layer and noble metal nanoparticle materials, the mask may be placed in an area where white light (e.g., daylight) is available to the surface. The semi-conductive nature of the film permits the surface to neutralize and / or destroy microbes that may have become exposed to the surface of the material, such as to destroy virus or bacteria. This decontaminating action may also be provided upon exposure of the material textile to ultraviolet light. This presents yet another advantage of the present materials and products as protective garments and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com