Manufacturing method of heat supply and warm-keeping ecological felt utilizing wind and light energy for high altitude area

A production method and high-altitude technology, applied in land preparation methods, applications, renewable energy machines, etc., can solve problems such as soil freezing and the inability of soil to provide heat sources, to overcome soil compaction, reduce plant death, and increase air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

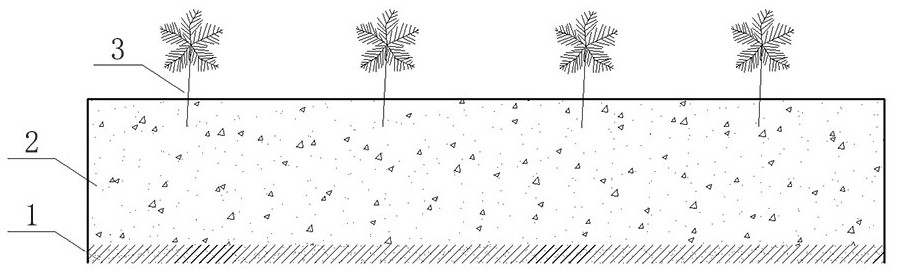

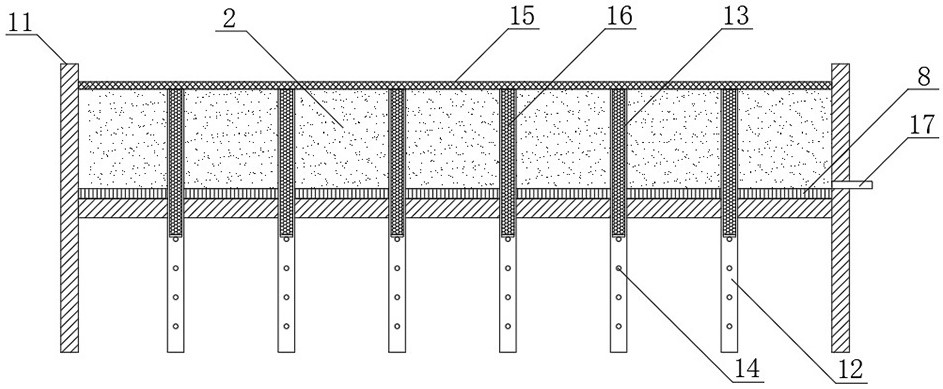

[0041] A method for manufacturing an ecological felt for heating with wind energy in high-altitude areas. The ecological felt includes a heat-retaining layer 1, a light substrate layer 2, and a vegetation layer 3. The manufacturing method includes the following steps:

[0042] S1, first make a thermal insulation layer for later use;

[0043] S2. Under indoor greenhouse conditions, lay the thermal insulation layer 20cm below the frozen soil. When the soil temperature reaches the temperature required by the plants, mix the light matrix and the thawed soil evenly to form a light matrix layer 2, the temperature required by the plants. The temperature is 15°C, the raw material of the light substrate is mushroom residue, animal manure, biochar, and the mass ratio of mixing with the thawed soil is 5:3:1:10, and the animal manure is sheep manure;

[0044] S3, sowing plant seeds at a depth of 21 cm in the light matrix layer, and carrying out maintenance and management of the plant seed...

Embodiment 2

[0047] A method for manufacturing an ecological felt for heating with wind energy in high-altitude areas. The ecological felt includes a heat-retaining layer 1, a light substrate layer 2, and a vegetation layer 3. The manufacturing method includes the following steps:

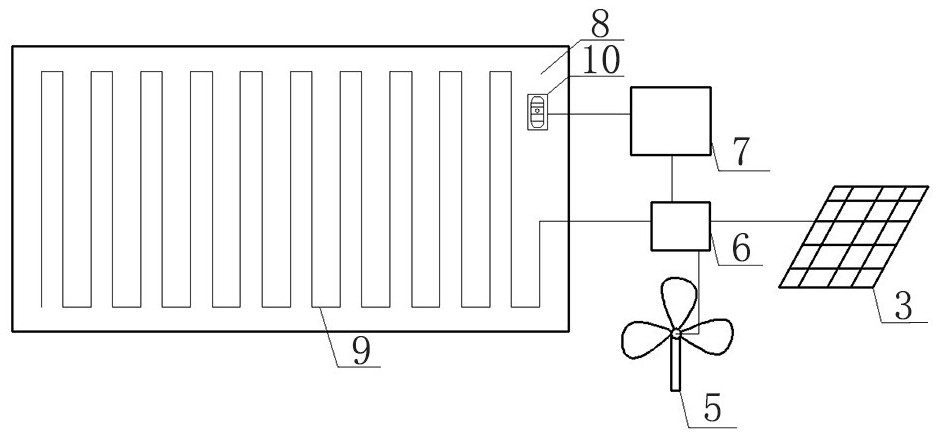

[0048] S1, thermal insulation layer 1 comprises solar panel 4, wind-driven generator 5, storage battery 6, intelligent control system 7, insulation cloth 8, resistance wire 9 is arranged in insulation cloth 8 and is connected with storage battery 6, and described insulation cloth 8 is also set There is a temperature sensor 10, the battery 6 is electrically connected to the solar panel 4 and the wind generator 5 respectively, and the intelligent control system 7 is electrically connected to the battery 6 and the temperature sensor 10 respectively;

[0049] S2. Under indoor greenhouse conditions, lay the insulating cloth 8 at a place 30 cm below the frozen soil. When the soil temperature reaches the temperature re...

Embodiment 3

[0053] A method for manufacturing an ecological felt for heating with wind energy in high-altitude areas. The ecological felt includes a heat-retaining layer 1, a light substrate layer 2, and a vegetation layer 3. The manufacturing method includes the following steps:

[0054] S1, thermal insulation layer 1 comprises solar panel 4, wind-driven generator 5, storage battery 6, intelligent control system 7, insulation cloth 8, resistance wire 9 is arranged in insulation cloth 8 and is connected with storage battery 6, and described insulation cloth 8 is also set There is a temperature sensor 10, the battery 6 is electrically connected to the solar panel 4 and the wind generator 5 respectively, and the intelligent control system 7 is electrically connected to the battery 6 and the temperature sensor 10 respectively;

[0055] S2. Under indoor greenhouse conditions, lay the insulating cloth 8 at 25 cm below the frozen soil. When the soil temperature reaches the temperature required b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Altitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com