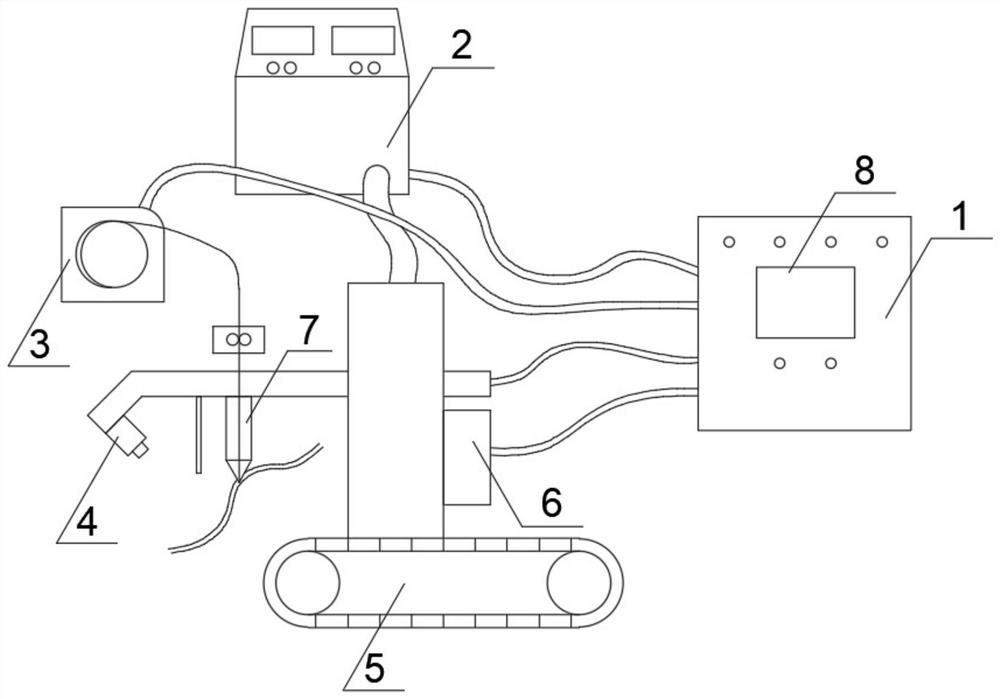

Centralized controller device of embedded crawling robot welding system

A technology of crawling robots and welding systems, applied in welding equipment, welding accessories, electrode support devices, etc., can solve the problems of large electromagnetic noise, large volume, affecting the stability of arc voltage, etc., to improve the quality of welding seam forming, expand the interface rich , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

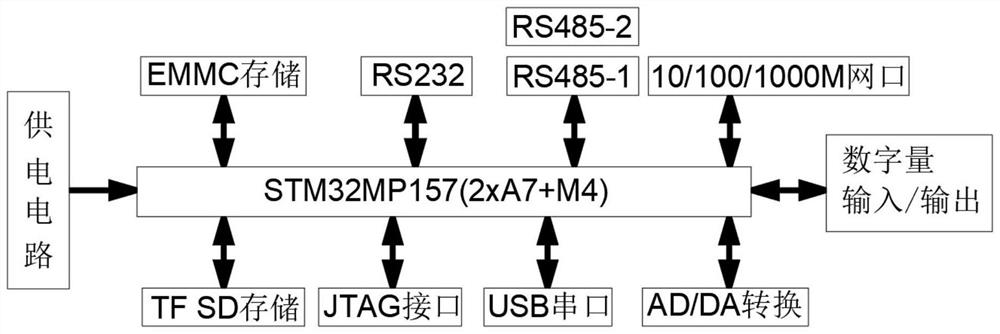

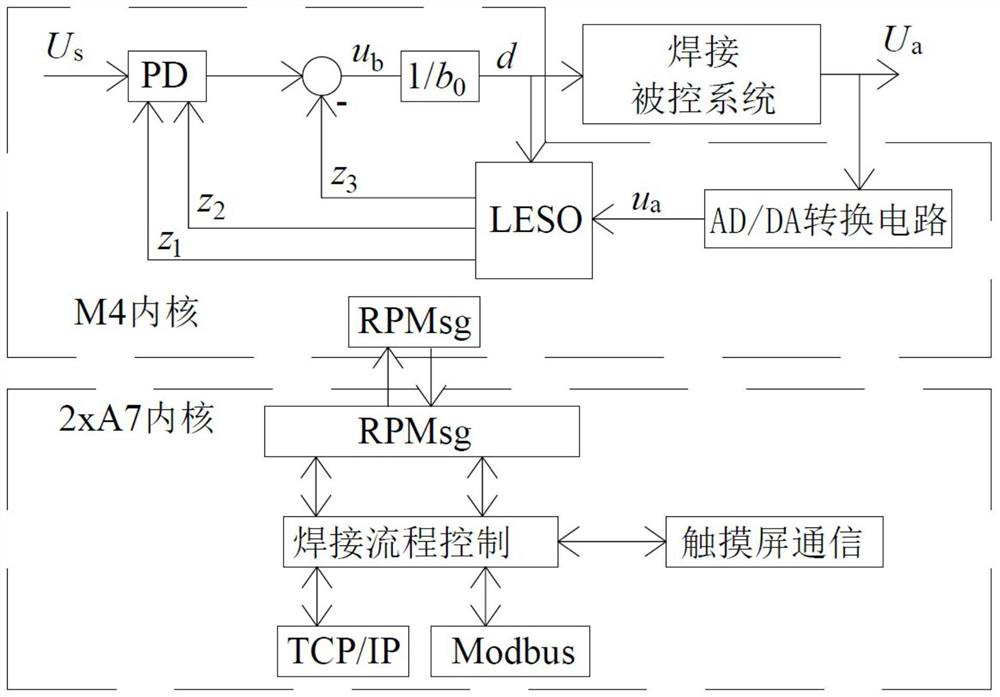

[0049] An embedded crawler robot welding system centralized controller device, such as figure 2 As shown, it includes a processor, a conversion circuit connected to the processor, a power supply circuit, a storage circuit, an interface circuit, a communication circuit, a digital input circuit and a digital output circuit.

[0050] In this embodiment, the processor adopts STM32MP157DAA1 multi-core heterogeneous chip, based on dual-core A7 800MHz main frequency and 209MHz M4 to form multi-core heterogeneous, integrated on one chip, running embedded Linux and FreeRTOS at the same time, respectively running on different kernels , in which the first A7 core and the second A7 core are connected to each other through a shared bus, run the embedded Linux system together, and distribute multiple threads to different A7 cores to achieve parallel computing and improve computing speed, while the dual A7 cores and M4 The core is also connected through the bus and receives processing infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com